6 - Association of Interior Specialists

6 - Association of Interior Specialists

6 - Association of Interior Specialists

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

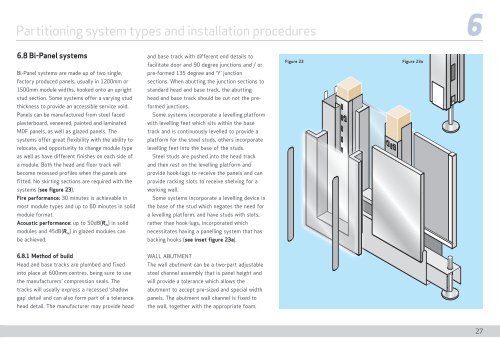

Partitioning system types and installation procedures 66.8 Bi-Panel systemsBi-Panel systems are made up <strong>of</strong> two single,factory produced panels, usually in 1200mm or1500mm module widths, hooked onto an uprightstud section. Some systems <strong>of</strong>fer a varying studthickness to provide an accessible service void.Panels can be manufactured from steel facedplasterboard, veneered, painted and laminatedMDF panels, as well as glazed panels. Thesystems <strong>of</strong>fer great flexibility with the ability torelocate, and opportunity to change module typeas well as have different finishes on each side <strong>of</strong>a module. Both the head and floor track willbecome recessed pr<strong>of</strong>iles when the panels arefitted. No skirting sections are required with thesystems (see figure 23).Fire performance: 30 minutes is achievable inmost module types and up to 60 minutes in solidmodule format.Acoustic performance: up to 50dB(R w ) in solidmodules and 45dB(R w ) in glazed modules canbe achieved.and base track with different end details t<strong>of</strong>acilitate door and 90 degree junctions and / orpre-formed 135 degree and ‘Y’ junctionsections. When abutting the junction sections tostandard head and base track, the abuttinghead and base track should be cut not the preformedjunctions.Some systems incorporate a levelling platformwith levelling feet which sits within the basetrack and is continuously levelled to provide aplatform for the steel studs, others incorporatelevelling feet into the base <strong>of</strong> the studs.Steel studs are pushed into the head trackand then rest on the levelling platform andprovide hook-lugs to receive the panels and canprovide racking slots to receive shelving for aworking wall.Some systems incorporate a levelling device inthe base <strong>of</strong> the stud which negates the need fora levelling platform, and have studs with slots,rather than hook-lugs, incorporated whichnecessitates having a panelling system that hasbacking hooks (see inset figure 23a).Figure 23Figure 23a6.8.1 Method <strong>of</strong> buildHead and base tracks are plumbed and fixedinto place at 600mm centres, being sure to usethe manufacturers’ compression seals. Thetracks will usually express a recessed ‘shadowgap’ detail and can also form part <strong>of</strong> a tolerancehead detail. The manufacturer may provide headWALL ABUTMENTThe wall abutment can be a two-part adjustablesteel channel assembly that is panel height andwill provide a tolerance which allows theabutment to accept pre-sized and special widthpanels. The abutment wall channel is fixed tothe wall, together with the appropriate foam,27