Partitioning system types and installation procedures 6compression seals and acoustic sealant. Once the levellingplatform has been levelled, a steel stud is inserted into anabutment stud channel and locked together by engaging withthe stud hook-lugs. This assembly is then inserted into thebase track and slid into the head track. When vertical theassembly is slid over the abutment wall channel.DOOR FRAMESDoor frames are factory prepared and painted and arriveon site ready to be hooked onto the studs either side <strong>of</strong>the door module. The studs should be carefully movedapart to allow the frame to be eased into position. Thestuds are then moved back into position to allow the doorframe to be pulled down over the hook-lugs on the steelstud and into position. It is advisable to hang the door laterto avoid any damage.GLAZED PANELSGlazed panels are delivered to site as sealed units, with aprotective film on the back, manufactured to half thepartition thickness, with locking strips built into thevertical edges. The panel is positioned on the floor infront <strong>of</strong> where it is about to be installed, then lifted intoposition and pushed back over the hook-lugs to meet thestud face and then pulled down over the hook-lugs into itsfinal position. The same occurs on the other side but thistime the protective film on the back <strong>of</strong> both panels shouldbe removed.Between all panel joints, a joint infill is cut to panel size andinserted in the gap. An acoustic seal is fitted in the horizontalgap between the panels and the head and base tracks.6.9 Monobloc systemsMonobloc systems are manufactured and assembled infactory conditions to either specific or standard dimensions.Each panel will arrive on site with its pre-finished face whichcan be solid, glazed, glazed with integral blinds, or half glazed.This enables a fast installation time on site, flexibility <strong>of</strong>design, and simple relocation benefits (see figure 24).Monobloc systems divide into three categories:1 Monobloc: generally full height, very good fire andacoustic specification, bespoke design, possibilities toaccommodate working wall, usually installed by themanufacturer2 Steel panel: which <strong>of</strong>fers standard and bespoke products,single or double skin, full or partial height, predominantlysteel or glazed modules, installed either by themanufacturer or the specialist contractor3 Cleanroom: which <strong>of</strong>fers technical solutions for themedical / high tec environment, installed either by themanufacturer or the specialist contractor6.9.1 Method <strong>of</strong> build – monobloc systemsMonobloc systems are set out with a head and floor channelwhich are fixed to the ceiling and floor and plumbed level.Any acoustic foams or seals are also fitted along with anysections that will allow for wireways at either the head orbase detail. Both the head and floor track will becomerecessed pr<strong>of</strong>iles when the panels are fitted no skirtingsections are required with the systems.Panels, which are factory manufactured in one piece, arethen fitted by being lifted up into the head track, which hassufficient depth for the panel to then be dropped down ontothe floor track. Seals at the head track are then inserted.Some systems have a single line junction without a coverstrip, enabled by a system that clips the panels together.Other system types push panels together leaving a 6mm gapbetween panel faces to allow a vinyl or steel seal to beinserted. Solid vertical junctions can accommodate aconcealed racking upright that facilitates the support <strong>of</strong>furniture items such as shelving, storage units and desking.The upright can be retr<strong>of</strong>itted and relocated if required.Movement (service) panels can be provided withremovable skins to allow installation and integration <strong>of</strong>electric switches and power sockets. Also small movementpanels can be installed next to each door.Doorsets also arrive to site pre manufactured with eithera steel, timber or glass door, complete with floor mounteddoor seals.Fire performance: <strong>of</strong> up to 60 minutes on solid and glazedelevations, 30 minutes on door modules. In certaincircumstances 90 minutes can be achieved on solidelevations.Acoustic performance: <strong>of</strong> up to 47dB(R w ) on solid elevations,45dB(R w ) on double glazed elevations and 43dB(R w ) on doormodules can be achieved, but higher performance solutionscan be provided as a bespoke manufacture.6.9.2 Method <strong>of</strong> build - steel panel systemsSteel panel systems are available in double or single skin(including steel mesh), fire and non-fire resisting. Full or partheight elevation and can be installed either by themanufacturer or the specialist contractor.28

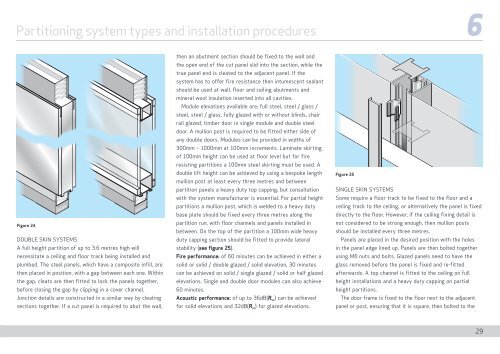

Partitioning system types and installation procedures 6Figure 24DOUBLE SKIN SYSTEMSA full height partition <strong>of</strong> up to 3.6 metres high willnecessitate a ceiling and floor track being installed andplumbed. The steel panels, which have a composite infill, arethen placed in position, with a gap between each one. Withinthe gap, cleats are then fitted to lock the panels together,before closing the gap by clipping in a cover channel.Junction details are constructed in a similar way by cleatingsections together. If a cut panel is required to abut the wall,then an abutment section should be fixed to the wall andthe open end <strong>of</strong> the cut panel slid into the section, while thetrue panel end is cleated to the adjacent panel. If thesystem has to <strong>of</strong>fer fire resistance then intumescent sealantshould be used at wall, floor and ceiling abutments andmineral wool insulation inserted into all cavities.Module elevations available are; full steel, steel / glass /steel, steel / glass, fully glazed with or without blinds, chairrail glazed, timber door in single module and double steeldoor. A mullion post is required to be fitted either side <strong>of</strong>any double doors. Modules can be provided in widths <strong>of</strong>300mm – 1000mm at 100mm increments. Laminate skirting<strong>of</strong> 100mm height can be used at floor level but for fireresisting partitions a 100mm steel skirting must be used. Adouble lift height can be achieved by using a bespoke lengthmullion post at least every three metres and betweenpartition panels a heavy duty top capping, but consultationwith the system manufacturer is essential. For partial heightpartitions a mullion post, which is welded to a heavy dutybase plate should be fixed every three metres along thepartition run, with floor channels and panels installed inbetween. On the top <strong>of</strong> the partition a 100mm wide heavyduty capping section should be fitted to provide lateralstability (see figure 25).Fire performance: <strong>of</strong> 60 minutes can be achieved in either asolid or solid / double glazed / solid elevation, 30 minutescan be achieved on solid / single glazed / solid or half glazedelevations. Single and double door modules can also achieve60 minutes.Acoustic performance: <strong>of</strong> up to 36dB(R w ) can be achievedfor solid elevations and 32dB(R w ) for glazed elevations.Figure 25SINGLE SKIN SYSTEMSSome require a floor track to be fixed to the floor and aceiling track to the ceiling, or alternatively the panel is fixeddirectly to the floor. However, if the ceiling fixing detail isnot considered to be strong enough, then mullion postsshould be installed every three metres.Panels are placed in the desired position with the holesin the panel edge lined up. Panels are then bolted togetherusing M6 nuts and bolts. Glazed panels need to have theglass removed before the panel is fixed and re-fittedafterwards. A top channel is fitted to the ceiling on fullheight installations and a heavy duty capping on partialheight partitions.The door frame is fixed to the floor next to the adjacentpanel or post, ensuring that it is square, then bolted to the29