Varian Linatron High-Energy X-ray Applications 2007

Varian Linatron High-Energy X-ray Applications 2007

Varian Linatron High-Energy X-ray Applications 2007

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

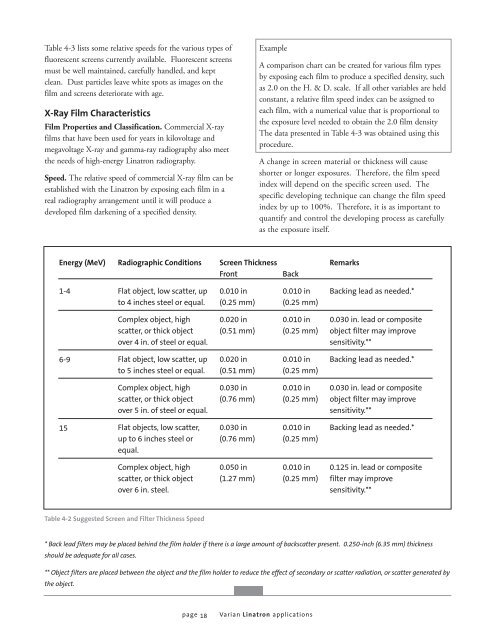

Table 4-3 lists some relative speeds for the various types of<br />

fluorescent screens currently available. Fluorescent screens<br />

must be well maintained, carefully handled, and kept<br />

clean. Dust particles leave white spots as images on the<br />

film and screens deteriorate with age.<br />

X-Ray Film Characteristics<br />

Film Properties and Classification. Commercial X-<strong>ray</strong><br />

films that have been used for years in kilovoltage and<br />

megavoltage X-<strong>ray</strong> and gamma-<strong>ray</strong> radiography also meet<br />

the needs of high-energy <strong>Linatron</strong> radiography.<br />

Speed. The relative speed of commercial X-<strong>ray</strong> film can be<br />

established with the <strong>Linatron</strong> by exposing each film in a<br />

real radiography arrangement until it will produce a<br />

developed film darkening of a specified density.<br />

<strong>Energy</strong> (MeV)<br />

1-4<br />

6-9<br />

15<br />

Radiographic Conditions<br />

Flat object, low scatter, up<br />

to 4 inches steel or equal.<br />

Complex object, high<br />

scatter, or thick object<br />

over 4 in. of steel or equal.<br />

Flat object, low scatter, up<br />

to 5 inches steel or equal.<br />

Complex object, high<br />

scatter, or thick object<br />

over 5 in. of steel or equal.<br />

Flat objects, low scatter,<br />

up to 6 inches steel or<br />

equal.<br />

Complex object, high<br />

scatter, or thick object<br />

over 6 in. steel.<br />

Table 4-2 Suggested Screen and Filter Thickness Speed<br />

page 18<br />

Example<br />

A comparison chart can be created for various film types<br />

by exposing each film to produce a specified density, such<br />

as 2.0 on the H. & D. scale. If all other variables are held<br />

constant, a relative film speed index can be assigned to<br />

each film, with a numerical value that is proportional to<br />

the exposure level needed to obtain the 2.0 film density<br />

The data presented in Table 4-3 was obtained using this<br />

procedure.<br />

A change in screen material or thickness will cause<br />

shorter or longer exposures. Therefore, the film speed<br />

index will depend on the specific screen used. The<br />

specific developing technique can change the film speed<br />

index by up to 100%. Therefore, it is as important to<br />

quantify and control the developing process as carefully<br />

as the exposure itself.<br />

Screen Thickness<br />

Front Back<br />

0.010 in 0.010 in<br />

(0.25 mm) (0.25 mm)<br />

0.020 in 0.010 in<br />

(0.51 mm) (0.25 mm)<br />

0.020 in 0.010 in<br />

(0.51 mm) (0.25 mm)<br />

0.030 in 0.010 in<br />

(0.76 mm) (0.25 mm)<br />

0.030 in 0.010 in<br />

(0.76 mm) (0.25 mm)<br />

0.050 in 0.010 in<br />

(1.27 mm) (0.25 mm)<br />

* Back lead filters may be placed behind the film holder if there is a large amount of backscatter present. 0.250-inch (6.35 mm) thickness<br />

should be adequate for all cases.<br />

** Object filters are placed between the object and the film holder to reduce the effect of secondary or scatter radiation, or scatter generated by<br />

the object.<br />

<strong>Varian</strong> <strong>Linatron</strong> applications<br />

Remarks<br />

Backing lead as needed.*<br />

0.030 in. lead or composite<br />

object filter may improve<br />

sensitivity.**<br />

Backing lead as needed.*<br />

0.030 in. lead or composite<br />

object filter may improve<br />

sensitivity.**<br />

Backing lead as needed.*<br />

0.125 in. lead or composite<br />

filter may improve<br />

sensitivity.**

![[MSDS 126] Dow Corning 200 Fluid, 5 CST Part Number ... - Varian](https://img.yumpu.com/5104917/1/190x245/msds-126-dow-corning-200-fluid-5-cst-part-number-varian.jpg?quality=85)