Varian Linatron High-Energy X-ray Applications 2007

Varian Linatron High-Energy X-ray Applications 2007

Varian Linatron High-Energy X-ray Applications 2007

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

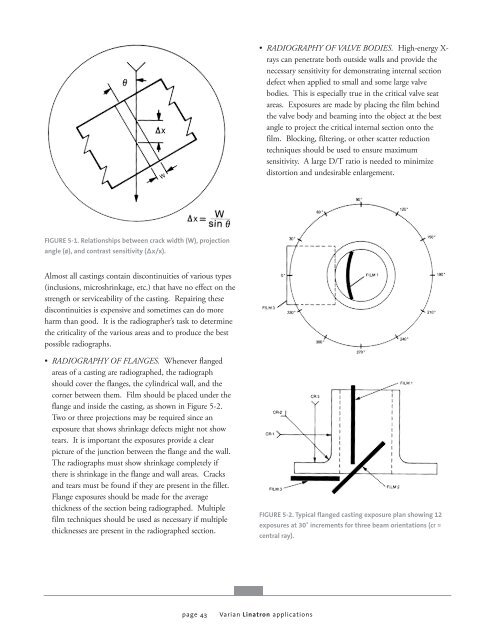

FIGURE 5-1. Relationships between crack width (W), projection<br />

angle (ø), and contrast sensitivity (Δx/x).<br />

Almost all castings contain discontinuities of various types<br />

(inclusions, microshrinkage, etc.) that have no effect on the<br />

strength or serviceability of the casting. Repairing these<br />

discontinuities is expensive and sometimes can do more<br />

harm than good. It is the radiographer’s task to determine<br />

the criticality of the various areas and to produce the best<br />

possible radiographs.<br />

• RADIOGRAPHY OF FLANGES. Whenever flanged<br />

areas of a casting are radiographed, the radiograph<br />

should cover the flanges, the cylindrical wall, and the<br />

corner between them. Film should be placed under the<br />

flange and inside the casting, as shown in Figure 5-2.<br />

Two or three projections may be required since an<br />

exposure that shows shrinkage defects might not show<br />

tears. It is important the exposures provide a clear<br />

picture of the junction between the flange and the wall.<br />

The radiographs must show shrinkage completely if<br />

there is shrinkage in the flange and wall areas. Cracks<br />

and tears must be found if they are present in the fillet.<br />

Flange exposures should be made for the average<br />

thickness of the section being radiographed. Multiple<br />

film techniques should be used as necessary if multiple<br />

thicknesses are present in the radiographed section.<br />

page 43<br />

• RADIOGRAPHY OF VALVE BODIES. <strong>High</strong>-energy X<strong>ray</strong>s<br />

can penetrate both outside walls and provide the<br />

necessary sensitivity for demonstrating internal section<br />

defect when applied to small and some large valve<br />

bodies. This is especially true in the critical valve seat<br />

areas. Exposures are made by placing the film behind<br />

the valve body and beaming into the object at the best<br />

angle to project the critical internal section onto the<br />

film. Blocking, filtering, or other scatter reduction<br />

techniques should be used to ensure maximum<br />

sensitivity. A large D/T ratio is needed to minimize<br />

distortion and undesirable enlargement.<br />

FIGURE 5-2. Typical flanged casting exposure plan showing 12<br />

exposures at 30˚ increments for three beam orientations (cr =<br />

central <strong>ray</strong>).<br />

<strong>Varian</strong> <strong>Linatron</strong> applications

![[MSDS 126] Dow Corning 200 Fluid, 5 CST Part Number ... - Varian](https://img.yumpu.com/5104917/1/190x245/msds-126-dow-corning-200-fluid-5-cst-part-number-varian.jpg?quality=85)