Varian Linatron High-Energy X-ray Applications 2007

Varian Linatron High-Energy X-ray Applications 2007

Varian Linatron High-Energy X-ray Applications 2007

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Drilled Hole Plaque Penetrameter Sensitivity. The<br />

drilled hole plaque is the standard American penetrameter<br />

for all radiography. It consists of a small rectangular strip<br />

of material with three drilled holes. Thickness of the<br />

penetrameter is specified as 1%, 2%, or more, of the object<br />

thickness. The three hole diameters are equal to 1 x T, 2 x<br />

T, and 4 x T where the thickness of the penetrameter “T”.<br />

Sensitivity is described in terms of the thickness percent (1,<br />

2, 4) and the required hole size that must be discerned.<br />

Example<br />

2-2T is the standard way to describe a penetrameter whose<br />

thickness must be 2% of the object thickness and whose 2<br />

x T hole must be seen on the film.<br />

Drilled hole sensitivity data for each <strong>Linatron</strong> show that all<br />

sources should demonstrate better than 1% sensitivity<br />

above 2 inches (50.8 mm) of steel, up to 10 HVLs, and<br />

better than 2% for thicknesses down to 1 inch (25.4 mm).<br />

Radiographic Sensitivity. Radiographic sensitivity refers<br />

to the ability to see and recognize a variety of defects and<br />

other internal conditions in the radiograph in this manual.<br />

Standard penetrameters provide an indicator of the level of<br />

image quality that is achieved with a particular<br />

radiographic technique used. Penetrameters do not,<br />

however, give defect size. Penetrameters must be placed on<br />

the source side of an object since the image improves as the<br />

defect occurs closer to the film.<br />

Exposure Curves<br />

The plot of exposure level that corresponds to a specific<br />

film density (2.0 for example) for each thickness of<br />

material is called an exposure curve. Exposure curves<br />

should be made for the <strong>Linatron</strong> after it is completely<br />

operational for all applications. Such curves represent<br />

operational data that are indicative of the operating<br />

characteristics of the setup. Subsequent exposure curves for<br />

the same setup should provide consistent results.<br />

page 25<br />

Established exposure curves also allow the radiographer to<br />

simplify the exposure calculation process. With these<br />

curves, the radiographer only needs to look up the required<br />

exposure level for that thickness and make the exposure. If<br />

the source-to-film distance must be changed, using the<br />

inverse square law provides the new exposure level. A<br />

change to a different film can lead to an additional<br />

adjustment of exposure level using the relative speed table.<br />

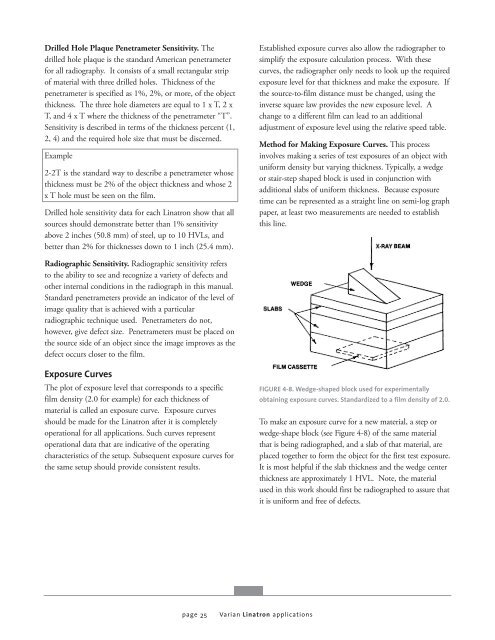

Method for Making Exposure Curves. This process<br />

involves making a series of test exposures of an object with<br />

uniform density but varying thickness. Typically, a wedge<br />

or stair-step shaped block is used in conjunction with<br />

additional slabs of uniform thickness. Because exposure<br />

time can be represented as a straight line on semi-log graph<br />

paper, at least two measurements are needed to establish<br />

this line.<br />

FIGURE 4-8. Wedge-shaped block used for experimentally<br />

obtaining exposure curves. Standardized to a film density of 2.0.<br />

To make an exposure curve for a new material, a step or<br />

wedge-shape block (see Figure 4-8) of the same material<br />

that is being radiographed, and a slab of that material, are<br />

placed together to form the object for the first test exposure.<br />

It is most helpful if the slab thickness and the wedge center<br />

thickness are approximately 1 HVL. Note, the material<br />

used in this work should first be radiographed to assure that<br />

it is uniform and free of defects.<br />

<strong>Varian</strong> <strong>Linatron</strong> applications

![[MSDS 126] Dow Corning 200 Fluid, 5 CST Part Number ... - Varian](https://img.yumpu.com/5104917/1/190x245/msds-126-dow-corning-200-fluid-5-cst-part-number-varian.jpg?quality=85)