Varian Linatron High-Energy X-ray Applications 2007

Varian Linatron High-Energy X-ray Applications 2007

Varian Linatron High-Energy X-ray Applications 2007

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The total unsharpness is reduced to include only inherent<br />

and geometrical unsharpness because they contribute much<br />

more than spot size to unsharpness. This reduces the<br />

expression the expression above to the following.<br />

UTOT = (U 2<br />

F + UG2 ) 1/2<br />

Example<br />

Let energy equal 2 MeV and focal spot equal 2 mm. If we<br />

use double emulsion film and automatic development,<br />

with U F = 0.3 mm, and a radiography arrangement where<br />

6 inches of steel are exposed with a D/T = 12, U TOT is:<br />

U TOT = (0.3 2 + (2/12) 2 ) 1/2 = 0.34 mm<br />

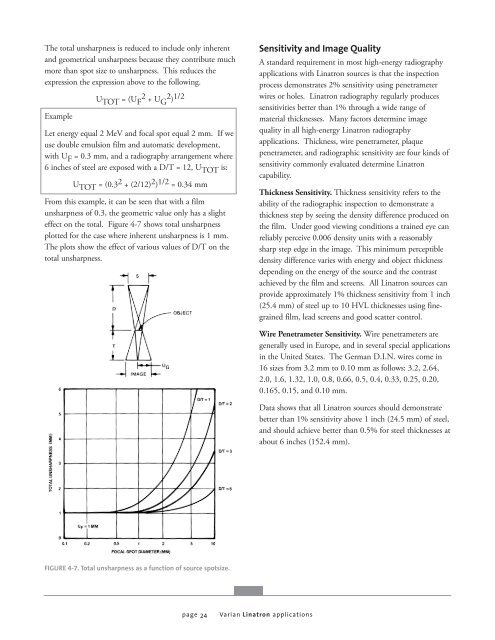

From this example, it can be seen that with a film<br />

unsharpness of 0.3, the geometric value only has a slight<br />

effect on the total. Figure 4-7 shows total unsharpness<br />

plotted for the case where inherent unsharpness is 1 mm.<br />

The plots show the effect of various values of D/T on the<br />

total unsharpness.<br />

FIGURE 4-7. Total unsharpness as a function of source spotsize.<br />

page 24<br />

Sensitivity and Image Quality<br />

A standard requirement in most high-energy radiography<br />

applications with <strong>Linatron</strong> sources is that the inspection<br />

process demonstrates 2% sensitivity using penetrameter<br />

wires or holes. <strong>Linatron</strong> radiography regularly produces<br />

sensitivities better than 1% through a wide range of<br />

material thicknesses. Many factors determine image<br />

quality in all high-energy <strong>Linatron</strong> radiography<br />

applications. Thickness, wire penetrameter, plaque<br />

penetrameter, and radiographic sensitivity are four kinds of<br />

sensitivity commonly evaluated determine <strong>Linatron</strong><br />

capability.<br />

Thickness Sensitivity. Thickness sensitivity refers to the<br />

ability of the radiographic inspection to demonstrate a<br />

thickness step by seeing the density difference produced on<br />

the film. Under good viewing conditions a trained eye can<br />

reliably perceive 0.006 density units with a reasonably<br />

sharp step edge in the image. This minimum perceptible<br />

density difference varies with energy and object thickness<br />

depending on the energy of the source and the contrast<br />

achieved by the film and screens. All <strong>Linatron</strong> sources can<br />

provide approximately 1% thickness sensitivity from 1 inch<br />

(25.4 mm) of steel up to 10 HVL thicknesses using finegrained<br />

film, lead screens and good scatter control.<br />

Wire Penetrameter Sensitivity. Wire penetrameters are<br />

generally used in Europe, and in several special applications<br />

in the United States. The German D.I.N. wires come in<br />

16 sizes from 3.2 mm to 0.10 mm as follows: 3.2, 2.64,<br />

2.0, 1.6, 1.32, 1.0, 0.8, 0.66, 0.5, 0.4, 0.33, 0.25, 0.20,<br />

0.165, 0.15, and 0.10 mm.<br />

Data shows that all <strong>Linatron</strong> sources should demonstrate<br />

better than 1% sensitivity above 1 inch (24.5 mm) of steel,<br />

and should achieve better than 0.5% for steel thicknesses at<br />

about 6 inches (152.4 mm).<br />

<strong>Varian</strong> <strong>Linatron</strong> applications

![[MSDS 126] Dow Corning 200 Fluid, 5 CST Part Number ... - Varian](https://img.yumpu.com/5104917/1/190x245/msds-126-dow-corning-200-fluid-5-cst-part-number-varian.jpg?quality=85)