Varian Linatron High-Energy X-ray Applications 2007

Varian Linatron High-Energy X-ray Applications 2007

Varian Linatron High-Energy X-ray Applications 2007

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

and then determining the approximate exposure level from<br />

the known value of exposure for object number 1 (Rl ), by<br />

R2e -μ2X2= R1e -μ1X1 Example<br />

The exposure of a 4-inch-thick (101.6 mm) bronze alloy<br />

(density = 9) may be estimated from the steel exposure<br />

curve at 2 MV by:<br />

μbronze = 0.693/0.8 X 9/7.85 = 1 inch-1 For 4 inches (101.6 mm) of steel, the exposure rads:<br />

R l = 150 rads.<br />

Therefore for bronze: R2 = 150 e-(.866)(4)<br />

e<br />

= 256 rads<br />

-(1)(4)<br />

Thus, an exposure curve for the bronze alloy can be<br />

constructed by calculating the exposure rads at two<br />

thicknesses, plotting these points, and connecting them<br />

with a straight line.<br />

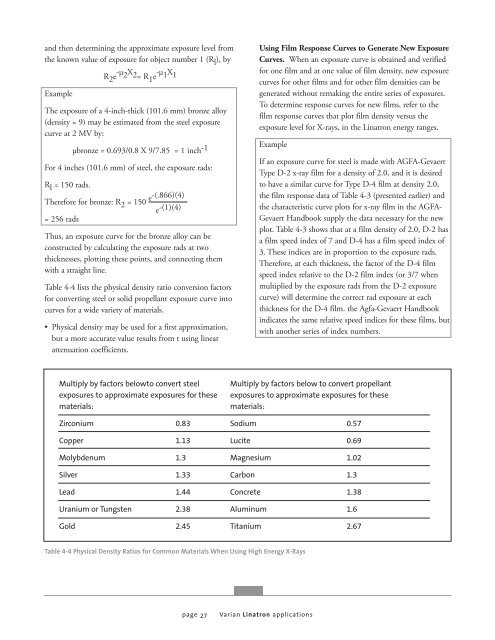

Table 4-4 lists the physical density ratio conversion factors<br />

for converting steel or solid propellant exposure curve into<br />

curves for a wide variety of materials.<br />

• Physical density may be used for a first approximation,<br />

but a more accurate value results from t using linear<br />

attenuation coefficients.<br />

Multiply by factors belowto convert steel<br />

exposures to approximate exposures for these<br />

materials:<br />

Zirconium 0.83<br />

Copper 1.13<br />

Molybdenum 1.3<br />

Silver 1.33<br />

Lead 1.44<br />

Uranium or Tungsten 2.38<br />

Gold 2.45<br />

page 27<br />

Using Film Response Curves to Generate New Exposure<br />

Curves. When an exposure curve is obtained and verified<br />

for one film and at one value of film density, new exposure<br />

curves for other films and for other film densities can be<br />

generated without remaking the entire series of exposures.<br />

To determine response curves for new films, refer to the<br />

film response curves that plot film density versus the<br />

exposure level for X-<strong>ray</strong>s, in the <strong>Linatron</strong> energy ranges.<br />

Example<br />

Table 4-4 Physical Density Ratios for Common Materials When Using <strong>High</strong> <strong>Energy</strong> X-Rays<br />

If an exposure curve for steel is made with AGFA-Gevaert<br />

Type D-2 x-<strong>ray</strong> film for a density of 2.0, and it is desired<br />

to have a similar curve for Type D-4 film at density 2.0,<br />

the film response data of Table 4-3 (presented earlier) and<br />

the characteristic curve plots for x-<strong>ray</strong> film in the AGFA-<br />

Gevaert Handbook supply the data necessary for the new<br />

plot. Table 4-3 shows that at a film density of 2.0, D-2 has<br />

a film speed index of 7 and D-4 has a film speed index of<br />

3. These indices are in proportion to the exposure rads.<br />

Therefore, at each thickness, the factor of the D-4 film<br />

speed index relative to the D-2 film index (or 3/7 when<br />

multiplied by the exposure rads from the D-2 exposure<br />

curve) will determine the correct rad exposure at each<br />

thickness for the D-4 film. the Agfa-Gevaert Handbook<br />

indicates the same relative speed indices for these films, but<br />

with another series of index numbers.<br />

Multiply by factors below to convert propellant<br />

exposures to approximate exposures for these<br />

materials:<br />

Sodium 0.57<br />

Lucite 0.69<br />

Magnesium 1.02<br />

Carbon 1.3<br />

Concrete 1.38<br />

Aluminum 1.6<br />

Titanium 2.67<br />

<strong>Varian</strong> <strong>Linatron</strong> applications

![[MSDS 126] Dow Corning 200 Fluid, 5 CST Part Number ... - Varian](https://img.yumpu.com/5104917/1/190x245/msds-126-dow-corning-200-fluid-5-cst-part-number-varian.jpg?quality=85)