FILARC flux - Esab

FILARC flux - Esab

FILARC flux - Esab

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

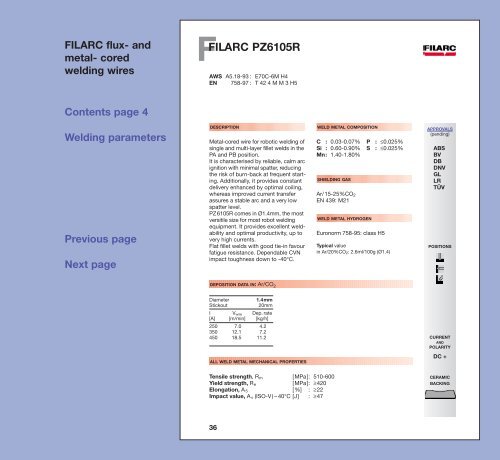

<strong>FILARC</strong> <strong>flux</strong>- andmetal- coredwelding wires<strong>FILARC</strong> PZ6105RAWS A5.18-93 : E70C-6M H4EN 758-97 : T 42 4 M M 3 H5Contents page 4Welding parametersPrevious pageNext pageDESCRIPTIONMetal-cored wire for robotic welding ofsingle and multi-layer fillet welds in thePA and PB position.It is characterised by reliable, calm arcignition with minimal spatter, reducingthe risk of burn-back at frequent starting.Additionally, it provides constantdelivery enhanced by optimal coiling,whereas improved current transferassures a stable arc and a very lowspatter level.PZ 6105R comes in Ø1.4mm, the mostversitile size for most robot weldingequipment. It provides excellent weldabilityand optimal productivity, up tovery high currents.Flat fillet welds with good tie-in favourfatigue resistance. Dependable CVNimpact toughness down to -40°C.WELD METAL COMPOSITIONC : 0.03-0.07% P : ≤0.025%Si : 0.60-0.90% S : ≤0.025%Mn: 1.40-1.80%SHIELDING GASAr/15-25%CO 2EN 439: M21WELD METAL HYDROGENEuronorm 758-95: class H5Typical valuein Ar/20%CO 2: 2.6ml/100g (Ø1.4)APPROVALS(pending)ABSBVDBDNVGLLRTÜVPOSITIONSDEPOSITION DATA IN: Ar/CO 2Diameter1.4mmStickout20mmI V wire Dep. rate[A] [m/min] [kg/h]250 7.0 4.2350 12.1 7.2450 18.5 11.2CURRENTANDPOLARITYALL WELD METAL MECHANICAL PROPERTIESDC +Tensile strength, R m [MPa]: 510-600Yield strength, R e[MPa]: ≥420Elongation, A 5 [%] : ≥22Impact value, A v (ISO-V) – 40°C [J] : ≥47CERAMICBACKING36