FilmTec Technical Manual - Chester Paul Company

FilmTec Technical Manual - Chester Paul Company

FilmTec Technical Manual - Chester Paul Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

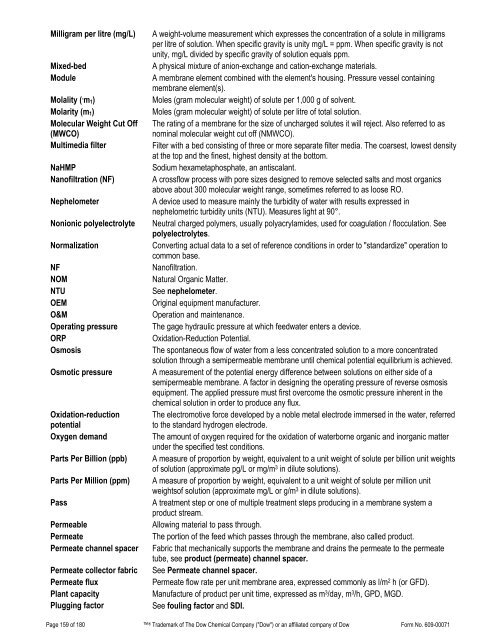

Milligram per litre (mg/L)Mixed-bedModuleMolality ( - m 1 )Molarity (m 1 )Molecular Weight Cut Off(MWCO)Multimedia filterNaHMPNanofiltration (NF)NephelometerNonionic polyelectrolyteNormalizationNFNOMNTUOEMO&MOperating pressureORPOsmosisOsmotic pressureOxidation-reductionpotentialOxygen demandParts Per Billion (ppb)Parts Per Million (ppm)PassPermeablePermeatePermeate channel spacerPermeate collector fabricPermeate fluxPlant capacityPlugging factorA weight-volume measurement which expresses the concentration of a solute in milligramsper litre of solution. When specific gravity is unity mg/L = ppm. When specific gravity is notunity, mg/L divided by specific gravity of solution equals ppm.A physical mixture of anion-exchange and cation-exchange materials.A membrane element combined with the element's housing. Pressure vessel containingmembrane element(s).Moles (gram molecular weight) of solute per 1,000 g of solvent.Moles (gram molecular weight) of solute per litre of total solution.The rating of a membrane for the size of uncharged solutes it will reject. Also referred to asnominal molecular weight cut off (NMWCO).Filter with a bed consisting of three or more separate filter media. The coarsest, lowest densityat the top and the finest, highest density at the bottom.Sodium hexametaphosphate, an antiscalant.A crossflow process with pore sizes designed to remove selected salts and most organicsabove about 300 molecular weight range, sometimes referred to as loose RO.A device used to measure mainly the turbidity of water with results expressed innephelometric turbidity units (NTU). Measures light at 90°.Neutral charged polymers, usually polyacrylamides, used for coagulation / flocculation. Seepolyelectrolytes.Converting actual data to a set of reference conditions in order to "standardize" operation tocommon base.Nanofiltration.Natural Organic Matter.See nephelometer.Original equipment manufacturer.Operation and maintenance.The gage hydraulic pressure at which feedwater enters a device.Oxidation-Reduction Potential.The spontaneous flow of water from a less concentrated solution to a more concentratedsolution through a semipermeable membrane until chemical potential equilibrium is achieved.A measurement of the potential energy difference between solutions on either side of asemipermeable membrane. A factor in designing the operating pressure of reverse osmosisequipment. The applied pressure must first overcome the osmotic pressure inherent in thechemical solution in order to produce any flux.The electromotive force developed by a noble metal electrode immersed in the water, referredto the standard hydrogen electrode.The amount of oxygen required for the oxidation of waterborne organic and inorganic matterunder the specified test conditions.A measure of proportion by weight, equivalent to a unit weight of solute per billion unit weightsof solution (approximate pg/L or mg/m 3 in dilute solutions).A measure of proportion by weight, equivalent to a unit weight of solute per million unitweightsof solution (approximate mg/L or g/m 3 in dilute solutions).A treatment step or one of multiple treatment steps producing in a membrane system aproduct stream.Allowing material to pass through.The portion of the feed which passes through the membrane, also called product.Fabric that mechanically supports the membrane and drains the permeate to the permeatetube, see product (permeate) channel spacer.See Permeate channel spacer.Permeate flow rate per unit membrane area, expressed commonly as l/m 2 h (or GFD).Manufacture of product per unit time, expressed as m 3 /day, m 3 /h, GPD, MGD.See fouling factor and SDI.Page 159 of 180 ® Trademark of The Dow Chemical <strong>Company</strong> ("Dow") or an affiliated company of Dow Form No. 609-00071