FilmTec Technical Manual - Chester Paul Company

FilmTec Technical Manual - Chester Paul Company

FilmTec Technical Manual - Chester Paul Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

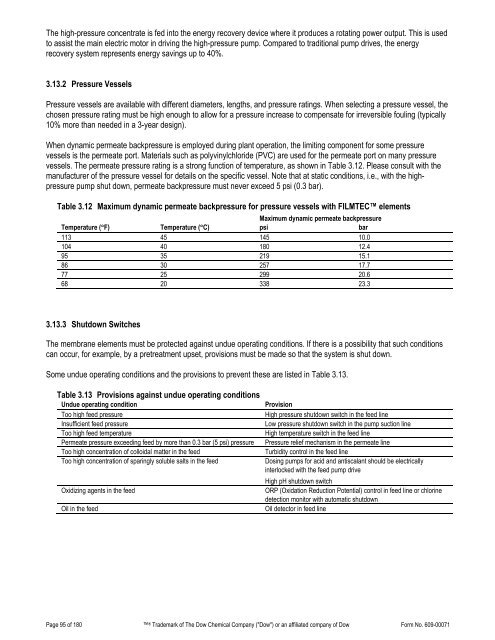

The high-pressure concentrate is fed into the energy recovery device where it produces a rotating power output. This is usedto assist the main electric motor in driving the high-pressure pump. Compared to traditional pump drives, the energyrecovery system represents energy savings up to 40%.3.13.2 Pressure VesselsPressure vessels are available with different diameters, lengths, and pressure ratings. When selecting a pressure vessel, thechosen pressure rating must be high enough to allow for a pressure increase to compensate for irreversible fouling (typically10% more than needed in a 3-year design).When dynamic permeate backpressure is employed during plant operation, the limiting component for some pressurevessels is the permeate port. Materials such as polyvinylchloride (PVC) are used for the permeate port on many pressurevessels. The permeate pressure rating is a strong function of temperature, as shown in Table 3.12. Please consult with themanufacturer of the pressure vessel for details on the specific vessel. Note that at static conditions, i.e., with the highpressurepump shut down, permeate backpressure must never exceed 5 psi (0.3 bar).Table 3.12 Maximum dynamic permeate backpressure for pressure vessels with FILMTEC elementsMaximum dynamic permeate backpressureTemperature (°F) Temperature (°C) psi bar113 45 145 10.0104 40 180 12.495 35 219 15.186 30 257 17.777 25 299 20.668 20 338 23.33.13.3 Shutdown SwitchesThe membrane elements must be protected against undue operating conditions. If there is a possibility that such conditionscan occur, for example, by a pretreatment upset, provisions must be made so that the system is shut down.Some undue operating conditions and the provisions to prevent these are listed in Table 3.13.Table 3.13 Provisions against undue operating conditionsUndue operating conditionToo high feed pressureInsufficient feed pressureToo high feed temperaturePermeate pressure exceeding feed by more than 0.3 bar (5 psi) pressureToo high concentration of colloidal matter in the feedToo high concentration of sparingly soluble salts in the feedOxidizing agents in the feedOil in the feedProvisionHigh pressure shutdown switch in the feed lineLow pressure shutdown switch in the pump suction lineHigh temperature switch in the feed linePressure relief mechanism in the permeate lineTurbidity control in the feed lineDosing pumps for acid and antiscalant should be electricallyinterlocked with the feed pump driveHigh pH shutdown switchORP (Oxidation Reduction Potential) control in feed line or chlorinedetection monitor with automatic shutdownOil detector in feed linePage 95 of 180 ® Trademark of The Dow Chemical <strong>Company</strong> ("Dow") or an affiliated company of Dow Form No. 609-00071