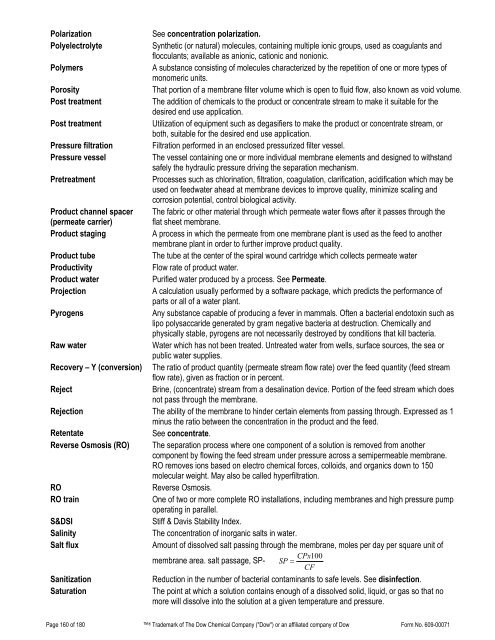

PolarizationSee concentration polarization.PolyelectrolyteSynthetic (or natural) molecules, containing multiple ionic groups, used as coagulants andflocculants; available as anionic, cationic and nonionic.PolymersA substance consisting of molecules characterized by the repetition of one or more types ofmonomeric units.PorosityThat portion of a membrane filter volume which is open to fluid flow, also known as void volume.Post treatmentThe addition of chemicals to the product or concentrate stream to make it suitable for thedesired end use application.Post treatmentUtilization of equipment such as degasifiers to make the product or concentrate stream, orboth, suitable for the desired end use application.Pressure filtrationFiltration performed in an enclosed pressurized filter vessel.Pressure vesselThe vessel containing one or more individual membrane elements and designed to withstandsafely the hydraulic pressure driving the separation mechanism.PretreatmentProcesses such as chlorination, filtration, coagulation, clarification, acidification which may beused on feedwater ahead at membrane devices to improve quality, minimize scaling andcorrosion potential, control biological activity.Product channel spacer The fabric or other material through which permeate water flows after it passes through the(permeate carrier)flat sheet membrane.Product stagingA process in which the permeate from one membrane plant is used as the feed to anothermembrane plant in order to further improve product quality.Product tubeThe tube at the center of the spiral wound cartridge which collects permeate waterProductivityFlow rate of product water.Product waterPurified water produced by a process. See Permeate.ProjectionA calculation usually performed by a software package, which predicts the performance ofparts or all of a water plant.PyrogensAny substance capable of producing a fever in mammals. Often a bacterial endotoxin such aslipo polysaccaride generated by gram negative bacteria at destruction. Chemically andphysically stable, pyrogens are not necessarily destroyed by conditions that kill bacteria.Raw waterWater which has not been treated. Untreated water from wells, surface sources, the sea orpublic water supplies.Recovery – Y (conversion) The ratio of product quantity (permeate stream flow rate) over the feed quantity (feed streamflow rate), given as fraction or in percent.RejectBrine, (concentrate) stream from a desalination device. Portion of the feed stream which doesnot pass through the membrane.Rejection The ability of the membrane to hinder certain elements from passing through. Expressed as 1minus the ratio between the concentration in the product and the feed.RetentateSee concentrate.Reverse Osmosis (RO) The separation process where one component of a solution is removed from anothercomponent by flowing the feed stream under pressure across a semipermeable membrane.RO removes ions based on electro chemical forces, colloids, and organics down to 150molecular weight. May also be called hyperfiltration.ROReverse Osmosis.RO trainOne of two or more complete RO installations, including membranes and high pressure pumpoperating in parallel.S&DSIStiff & Davis Stability Index.SalinityThe concentration of inorganic salts in water.Salt fluxAmount of dissolved salt passing through the membrane, moles per day per square unit ofCPx100membrane area. salt passage, SP- SP =CFSanitizationReduction in the number of bacterial contaminants to safe levels. See disinfection.SaturationThe point at which a solution contains enough of a dissolved solid, liquid, or gas so that nomore will dissolve into the solution at a given temperature and pressure.Page 160 of 180 ® Trademark of The Dow Chemical <strong>Company</strong> ("Dow") or an affiliated company of Dow Form No. 609-00071

SBS Sodium bisulfite, NaHSO 3.Scale inhibitorA chemical which inhibits the growth of micro-crystals (inhibits precipitation of sparinglysoluble salts). See antiscalant.ScalingThe build-up of precipitated salts on a surface, such as membranes, pipes, tanks, or boilercondensate tubesSDI - Salt Density Index An index calculated from the rate of plugging of 0.45 µm membrane filter. It is an indication ofthe amount of particulate matter in water, sometimes called fouling index.S&DSIStiff and Davis saturation index, measure of CaCO 3 solubility in seawater or highly salinewater. See LSI.SeawaterWater with an approximate concentration of total dissolved solids ranging from 30,000 to60,000 mg/L. See brackish water, high brackish water.SedimentationThe precipitation or settling of insoluble materials from a suspension, either by gravity orartificially. For example, centrifuge, pressure.Semipermeable membrane A membrane which preferentially allows the passage of specific compounds while rejectingothers.SHMPSodium HexaMetaPhosphate. (NaHMP).SiemensA measure of electrical conductance in water, equivalent to a mho. See Mho, Ohm.SlimeBiological deposits of gelatinous or filamentous matter.SMBS Sodium MetaBiSulfite, Na 2 S 2 O 5.SofteningSee membrane softening.SoftenerWater treatment equipment that uses a sodium based ion-exchange resin principally toremove cations as calcium and magnesium.Solids contact clarifier Water treating device used in lime softening, waste water treatment and coagulation processes.Solubility product[M + ] a [X - ] b /[MX] where the brackets indicate the concentrations of the components of theionization equilibrium M a X b aM + + bX. For sparingly soluble salts [MX] is essentially unity.SolutesMatter dissolved in a solvent.SolventHere defined as water.SPCStandard (heterotrophic) plate count. Measurement method for enumerating bacteria.Specific fluxFlux divided by net pressure driving force.Spiral wound cartridge A crossflow membrane element design consisting of a product tube, flat membrane leaves,feed channel spacers, anti-telescoping devices, and brine (concentrate) seal.Spiral wound membrane A flat sheet membrane with one or more feed channel spacers and barrier layers, all of whichare rolled into a spiral configuration.StageA sequestial arrangement of pressure vessels, usually reject staged such as 2:1 array,sometimes permeate staged as in double pass RO.StagingSee brine staging and product staging.Standard test conditions The parameters under which a membrane manufacturer tests devices for flow and saltrejection.SterilizationDestruction or removal of all viable organisms.Stiff & Davis StabilityIndex, S&DSIAn index calculated from total dissolved solids, calcium concentration, total alkalinity, pH andsolution temperature that shows the tendency of a water solution to precipitate or dissolvecalcium carbonate. S&DSI is used primarily for seawater RO applications.STPSodium triphosphate - Na 5 P 3 O 10 , a cleaning agent.STPPSodium tripolyphosphate. See STP.SupersaturationA state in which the inorganic salt(s) are in solution at a level higher than the respectivesolubility product.Suspended solids (SS) Solid organic and inorganic particles that are held in suspension in a liquid.SWROSeawater reverse osmosis.System salt passage SPS is the concentration of a compound in the permeate related to its concentration in thefeed water, also called apparent salt passage.TBCTotal Bacteria Count, the total number of viable microorganisms present in the sample,excluding anaerobic organisms.Page 161 of 180 ® Trademark of The Dow Chemical <strong>Company</strong> ("Dow") or an affiliated company of Dow Form No. 609-00071

- Page 1 and 2:

DowWater SolutionsFILMTEC Reverse O

- Page 3:

2.6 Biological Fouling Prevention .

- Page 7 and 8:

1. Basics of Reverse Osmosis and Na

- Page 9 and 10:

Nanofiltration (NF)Nanofiltration r

- Page 11 and 12:

How to Use Reverse Osmosis and Nano

- Page 13 and 14:

1.4 Membrane DescriptionThe FILMTEC

- Page 15 and 16:

Membrane systems are typically desi

- Page 17 and 18:

1.8 Element CharacteristicsFILMTEC

- Page 19 and 20:

2. Water Chemistry and Pretreatment

- Page 21 and 22:

SeawaterSeawater with TDS of 35,000

- Page 23 and 24:

Table 2.5 Water analysis for RO/NFS

- Page 25 and 26:

Table 2.7 Solubility products of sp

- Page 27 and 28:

In this process, only Ca 2+ , Ba 2+

- Page 29 and 30:

For the concentration ranges presen

- Page 31 and 32:

The conditions for CaCO 3 scale con

- Page 33 and 34:

Figure 2.3 Langelier saturation ind

- Page 35 and 36:

These computations have been descri

- Page 37 and 38:

Figure 2.5 “K” versus ionic str

- Page 39 and 40:

Figure 2.6 Ksp for CaSO 4 versus io

- Page 41 and 42:

2.4.6 Calcium Fluoride Scale Preven

- Page 43 and 44:

Figure 2.8 K sp for SrSO 4 versus i

- Page 45 and 46:

2.4.7 Silica Scale PreventionDissol

- Page 47 and 48:

Table 2.10 Solubility of SiO 2 vers

- Page 49 and 50:

2.4.8 Calcium Phosphate Scale Preve

- Page 51 and 52:

Table 2.9 Various fouling indicesIn

- Page 53 and 54:

Frequent shutdowns and start-ups sh

- Page 55 and 56:

If the differential pressure across

- Page 57 and 58:

1. Intake (surface) or well, before

- Page 59 and 60:

or combined residual chlorine (CRC)

- Page 61 and 62:

2.6.5 DBNPADBNPA (2,2, dibromo-3-ni

- Page 63 and 64:

2.6.11 Use of Fouling Resistant Mem

- Page 65 and 66:

2.11 Treatment of Feedwater Contain

- Page 67 and 68:

2.13 Summary of Pretreatment Option

- Page 69 and 70:

26. Handbook of Industrial Membrane

- Page 71 and 72:

Table 3.1 System design information

- Page 73 and 74:

3.2 Batch vs. Continuous ProcessAn

- Page 75 and 76:

3.4 Single-Stage SystemIn a single-

- Page 77 and 78:

The apparent salt passage of the sy

- Page 79 and 80:

Instead of having a separate high-p

- Page 81 and 82:

3.9.1 Membrane System Design Guidel

- Page 83 and 84:

In Table 3.6, the small commercial

- Page 85 and 86:

Table 3.8 Number of stages of a sea

- Page 87 and 88:

3.11 System Performance Projection3

- Page 89 and 90:

3.11.2 Design Equations and Paramet

- Page 91 and 92:

Table 3.10 Design equations for pro

- Page 93 and 94:

3.11.3 Comparing Actual Performance

- Page 95 and 96:

The high-pressure concentrate is fe

- Page 97 and 98:

If the product water from an RO sys

- Page 99 and 100:

Besides the above recommendations,

- Page 101 and 102:

4. Loading of Pressure VesselsThis

- Page 103 and 104:

The process of shimming is performe

- Page 105 and 106:

4.5.2 Summary of Large Element Inte

- Page 107 and 108:

5. System Operation5.1 Introduction

- Page 109 and 110: 5.2.3 Start-Up SequenceProper start

- Page 111 and 112: 5.2.4 Membrane Start-Up Performance

- Page 113 and 114: 5.5.3 SeawaterIn principle, the ope

- Page 115 and 116: Table 5.1 Reverse osmosis operating

- Page 117 and 118: A. Normalized Permeate FlowQS=ΔPsP

- Page 119 and 120: For the operating conditions we hav

- Page 121 and 122: 4. During recirculation of cleaning

- Page 123 and 124: 2. The cleaning pump should be size

- Page 125 and 126: 6.7 Effect of pH on Foulant Removal

- Page 127 and 128: Cleaning ProcedureThere are seven s

- Page 129 and 130: If the organic fouling is the resul

- Page 131 and 132: There are two factors that greatly

- Page 133 and 134: 7. Handling, Preservation and Stora

- Page 135 and 136: 7.4 Preservation of RO and NF Syste

- Page 137 and 138: If the normalized actual performanc

- Page 139 and 140: 8.3.3 Localization of High Solute P

- Page 141 and 142: Figure 8.2 Permeate probing apparat

- Page 143 and 144: 8.4.5 Performance TestThe standard

- Page 145 and 146: 8.5.1.1 Low Flow and Normal Solute

- Page 147 and 148: . Metal Oxide FoulingMetal oxide fo

- Page 149 and 150: . Organic FoulingThe adsorption of

- Page 151 and 152: 8.5.3 High Pressure DropHigh differ

- Page 153 and 154: In case of fullfit or heat sanitiza

- Page 155 and 156: Breakpoint chlorinationBreak tankBr

- Page 157 and 158: FeedThe input solution to a treatme

- Page 159: Milligram per litre (mg/L)Mixed-bed

- Page 163 and 164: 9.2 Specific Conductance of Sodium

- Page 165 and 166: Figure 9.1 Conductivity of ionic so

- Page 167 and 168: 9.6 Temperature Correction FactorTa

- Page 169 and 170: 9.9 Osmotic Pressure of Sodium Chlo

- Page 171 and 172: Details - TestEquipment andSpecific

- Page 173 and 174: satisfactory for such a determinati

- Page 175 and 176: case for almost all tested biocides

- Page 177 and 178: 9.12 Key Word IndexAbrasion - 150 B

- Page 179 and 180: Positive displacement pump - 95 Shu