FilmTec Technical Manual - Chester Paul Company

FilmTec Technical Manual - Chester Paul Company

FilmTec Technical Manual - Chester Paul Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

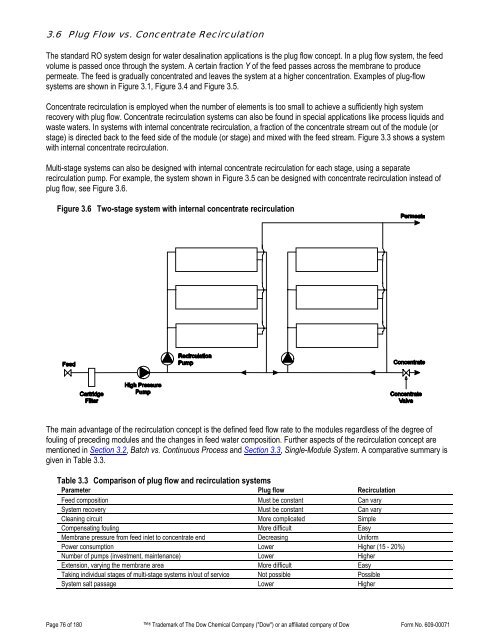

3.6 Plug Flow vs. Concentrate RecirculationThe standard RO system design for water desalination applications is the plug flow concept. In a plug flow system, the feedvolume is passed once through the system. A certain fraction Y of the feed passes across the membrane to producepermeate. The feed is gradually concentrated and leaves the system at a higher concentration. Examples of plug-flowsystems are shown in Figure 3.1, Figure 3.4 and Figure 3.5.Concentrate recirculation is employed when the number of elements is too small to achieve a sufficiently high systemrecovery with plug flow. Concentrate recirculation systems can also be found in special applications like process liquids andwaste waters. In systems with internal concentrate recirculation, a fraction of the concentrate stream out of the module (orstage) is directed back to the feed side of the module (or stage) and mixed with the feed stream. Figure 3.3 shows a systemwith internal concentrate recirculation.Multi-stage systems can also be designed with internal concentrate recirculation for each stage, using a separaterecirculation pump. For example, the system shown in Figure 3.5 can be designed with concentrate recirculation instead ofplug flow, see Figure 3.6.Figure 3.6 Two-stage system with internal concentrate recirculationThe main advantage of the recirculation concept is the defined feed flow rate to the modules regardless of the degree offouling of preceding modules and the changes in feed water composition. Further aspects of the recirculation concept arementioned in Section 3.2, Batch vs. Continuous Process and Section 3.3, Single-Module System. A comparative summary isgiven in Table 3.3.Table 3.3 Comparison of plug flow and recirculation systemsParameter Plug flow RecirculationFeed composition Must be constant Can varySystem recovery Must be constant Can varyCleaning circuit More complicated SimpleCompensating fouling More difficult EasyMembrane pressure from feed inlet to concentrate end Decreasing UniformPower consumption Lower Higher (15 - 20%)Number of pumps (investment, maintenance) Lower HigherExtension, varying the membrane area More difficult EasyTaking individual stages of multi-stage systems in/out of service Not possible PossibleSystem salt passage Lower HigherPage 76 of 180 ® Trademark of The Dow Chemical <strong>Company</strong> ("Dow") or an affiliated company of Dow Form No. 609-00071