- Page 2:

DESIGN AND DEVELOPMENTOF MEDICAL EL

- Page 8:

Copyright © 2005 by John Wiley & S

- Page 14:

CONTENTSPREFACEDISCLAIMERABOUT THE

- Page 20:

xPREFACEThe book addresses the prac

- Page 26:

DISCLAIMERThe projects in this book

- Page 30:

ABOUT THE AUTHORSDavid Prutchi is V

- Page 36:

2 BIOPOTENTIAL AMPLIFIERSGainG70.7%

- Page 40:

4 BIOPOTENTIAL AMPLIFIERSVolumeCond

- Page 44:

6 BIOPOTENTIAL AMPLIFIERSWarning! T

- Page 48:

8 BIOPOTENTIAL AMPLIFIERSIfRf-VccRi

- Page 52:

10 BIOPOTENTIAL AMPLIFIERSFigure 1.

- Page 56:

12 BIOPOTENTIAL AMPLIFIERSof the sk

- Page 60:

14 BIOPOTENTIAL AMPLIFIERScontamina

- Page 64:

16 BIOPOTENTIAL AMPLIFIERSFigure 1.

- Page 68:

18 BIOPOTENTIAL AMPLIFIERSFigure 1.

- Page 72:

20 BIOPOTENTIAL AMPLIFIERSA way of

- Page 76:

22 BIOPOTENTIAL AMPLIFIERSskin- ele

- Page 80:

24 BIOPOTENTIAL AMPLIFIERSFigure 1.

- Page 84:

26 BIOPOTENTIAL AMPLIFIERSOscillosc

- Page 88:

28 BIOPOTENTIAL AMPLIFIERS+15VV 132

- Page 92:

X1KX100X10JP2Sense3 2 13 2 14 5 6JP

- Page 96:

32 BIOPOTENTIAL AMPLIFIERSgenerator

- Page 100:

34 BIOPOTENTIAL AMPLIFIERSFigure 1.

- Page 104:

36 BIOPOTENTIAL AMPLIFIERSresults i

- Page 108:

38 BIOPOTENTIAL AMPLIFIERSUsing off

- Page 112:

40 BIOPOTENTIAL AMPLIFIERSFigure 1.

- Page 116:

42 BANDPASS SELECTION FOR BIOPOTENT

- Page 120:

44 BANDPASS SELECTION FOR BIOPOTENT

- Page 124:

46 BANDPASS SELECTION FOR BIOPOTENT

- Page 128:

48 BANDPASS SELECTION FOR BIOPOTENT

- Page 132:

50 BANDPASS SELECTION FOR BIOPOTENT

- Page 136:

52 BANDPASS SELECTION FOR BIOPOTENT

- Page 140:

54 BANDPASS SELECTION FOR BIOPOTENT

- Page 144:

56 BANDPASS SELECTION FOR BIOPOTENT

- Page 148:

5V_ISOIR25.1MR35.1MIR11M2374 8-+65V

- Page 152:

60 BANDPASS SELECTION FOR BIOPOTENT

- Page 156:

62Figure 2.14 State-variable filter

- Page 160:

64Figure 2.16 Since the cutoff freq

- Page 164:

66Figure 2.17 PSpice simulation res

- Page 168:

68 BANDPASS SELECTION FOR BIOPOTENT

- Page 172:

70 BANDPASS SELECTION FOR BIOPOTENT

- Page 176:

OUTOutputOut GND6R42kIC 1UAF42 8Hig

- Page 180:

-OUTOUTGNDININPUTINGND11R5100k1213+

- Page 184:

76 BANDPASS SELECTION FOR BIOPOTENT

- Page 188:

78 BANDPASS SELECTION FOR BIOPOTENT

- Page 192:

80 BANDPASS SELECTION FOR BIOPOTENT

- Page 196:

82 BANDPASS SELECTION FOR BIOPOTENT

- Page 200:

84 BANDPASS SELECTION FOR BIOPOTENT

- Page 204:

86Figure 2.35 The slew-rate limiter

- Page 208:

88 BANDPASS SELECTION FOR BIOPOTENT

- Page 212:

J3OUTPUTBNC2CR81.05KIC 2C406654 3LP

- Page 216:

IC5DCD4093B11CDisplay_InAD131N41484

- Page 220:

OUT+5V_ISOC122uF3284+-IC1A1OPA2130+

- Page 226:

3DESIGN OF SAFE MEDICALDEVICE PROTO

- Page 230:

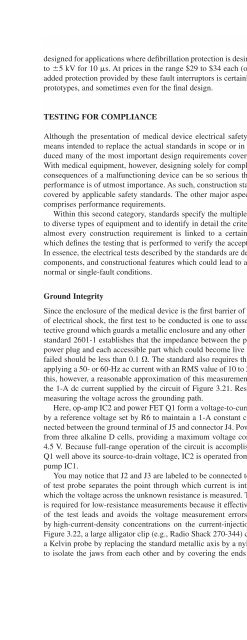

STANDARDS FOR PROTECTION AGAINST EL

- Page 234: LEAKAGE CURRENTS 1011. Ground leaka

- Page 238: Figure 3.2 A universal differential

- Page 242: DESIGN EXAMPLE: ISOLATED DIFFERENTI

- Page 246: -15VC6+15VC5.01uFIC2.01uF UA741 -15

- Page 250: ANALOG SIGNAL ISOLATION USING OPTIC

- Page 254: LINEAR ANALOG ISOLATION USING OPTOI

- Page 258: LINEAR ANALOG ISOLATION USING OPTOI

- Page 262: NON ISO.POWERSignalOutputJP312ISO.P

- Page 266: ISOLATEDPOWERINPUTJ4ISOLATED SIDENO

- Page 270: DIGITAL ALTERNATIVE TO SIGNAL ISOLA

- Page 274: SOFTWARE FOR THE ISOLATED A/D 121LP

- Page 278: POWER SUPPLIES 123Figure 3.17 The n

- Page 282: ADDITIONAL PROTECTION 125In additio

- Page 288: KELVINPROBEToDVMBT21.5V "D" CellF11

- Page 292: 130 DESIGN OF SAFE MEDICAL DEVICE P

- Page 296: PatientConnectionsPatientConnection

- Page 300: MeasuringDeviceSelectorPatientConne

- Page 304: 136 DESIGN OF SAFE MEDICAL DEVICE P

- Page 308: 15VAC115VAC2ISO 125VACDUT GND SENSE

- Page 312: +12V+15V+7V-15V-7V+ C176.8uF+ C166.

- Page 316: 117VACHOTNEUTRAL12MAIN ACPOWERSW2SW

- Page 320: TRIPD61N4148BufferR220k 1.0%Precisi

- Page 324: 146 DESIGN OF SAFE MEDICAL DEVICE P

- Page 328: 148 ELECTROMAGNETIC COMPATIBILITY A

- Page 332: 150 ELECTROMAGNETIC COMPATIBILITY A

- Page 336:

152 ELECTROMAGNETIC COMPATIBILITY A

- Page 340:

154 ELECTROMAGNETIC COMPATIBILITY A

- Page 344:

156 ELECTROMAGNETIC COMPATIBILITY A

- Page 348:

158 ELECTROMAGNETIC COMPATIBILITY A

- Page 352:

160 ELECTROMAGNETIC COMPATIBILITY A

- Page 356:

162 ELECTROMAGNETIC COMPATIBILITY A

- Page 360:

164Figure 4.11 The intermediate-fre

- Page 364:

166 ELECTROMAGNETIC COMPATIBILITY A

- Page 368:

168 ELECTROMAGNETIC COMPATIBILITY A

- Page 372:

Metal BoxHot(Black)L150uHC11.0uF 40

- Page 376:

172 ELECTROMAGNETIC COMPATIBILITY A

- Page 380:

174 ELECTROMAGNETIC COMPATIBILITY A

- Page 384:

176 ELECTROMAGNETIC COMPATIBILITY A

- Page 388:

178 ELECTROMAGNETIC COMPATIBILITY A

- Page 392:

180 ELECTROMAGNETIC COMPATIBILITY A

- Page 396:

182 ELECTROMAGNETIC COMPATIBILITY A

- Page 400:

184 ELECTROMAGNETIC COMPATIBILITY A

- Page 404:

186 ELECTROMAGNETIC COMPATIBILITY A

- Page 408:

188 ELECTROMAGNETIC COMPATIBILITY A

- Page 412:

190 ELECTROMAGNETIC COMPATIBILITY A

- Page 416:

192 ELECTROMAGNETIC COMPATIBILITY A

- Page 420:

194 ELECTROMAGNETIC COMPATIBILITY A

- Page 424:

196 ELECTROMAGNETIC COMPATIBILITY A

- Page 428:

198 ELECTROMAGNETIC COMPATIBILITY A

- Page 432:

200 ELECTROMAGNETIC COMPATIBILITY A

- Page 436:

202 ELECTROMAGNETIC COMPATIBILITY A

- Page 442:

5SIGNAL CONDITIONING, DATA ACQUISIT

- Page 446:

UNIVERSAL SENSOR INTERFACE 207Figur

- Page 450:

Figure 5.3 Schematic diagram of the

- Page 454:

UNIVERSAL SENSOR INTERFACE 211As co

- Page 458:

UNIVERSAL SENSOR INTERFACE 213dat

- Page 462:

UNIVERSAL SENSOR INTERFACE 215TABLE

- Page 466:

UNIVERSAL SENSOR INTERFACE 217For d

- Page 470:

UNIVERSAL SENSOR INTERFACE 219Figur

- Page 474:

UNIVERSAL SENSOR INTERFACE 22111421

- Page 478:

UNIVERSAL SENSOR INTERFACE 223TO J2

- Page 482:

SAMPLING RATE AND THE NYQUIST THEOR

- Page 486:

FREE DATA ACQUISITION CARD IN YOUR

- Page 490:

OUTOUTGNDTOSOUNDCARDR1C110kR21000.1

- Page 494:

FREE DATA ACQUISITION CARD IN YOUR

- Page 498:

SPECTRAL ANALYSIS 233TABLE 5.4 Some

- Page 502:

SPECTRAL ANALYSIS 235In most instan

- Page 506:

w n x n e 2πjf n ∆t X( f ) ∆t

- Page 510:

SPECTRAL ANALYSIS 239High-Resolutio

- Page 514:

SPECTRAL ANALYSIS 241Figure 5.19 Po

- Page 518:

SPECTRAL ANALYSIS 243order, but an

- Page 522:

SPECTRAL ANALYSIS 245Figure 5.21 A

- Page 526:

REFERENCES 247apart over the biceps

- Page 532:

250 SIGNAL SOURCES FOR SIMULATION,

- Page 536:

252 SIGNAL SOURCES FOR SIMULATION,

- Page 540:

254 SIGNAL SOURCES FOR SIMULATION,

- Page 544:

256 SIGNAL SOURCES FOR SIMULATION,

- Page 548:

OUTPUTJ2SMBR10502WJP1JUMPER 3JP2JUM

- Page 552:

260 SIGNAL SOURCES FOR SIMULATION,

- Page 556:

262 SIGNAL SOURCES FOR SIMULATION,

- Page 560:

264 SIGNAL SOURCES FOR SIMULATION,

- Page 564:

266 SIGNAL SOURCES FOR SIMULATION,

- Page 568:

T112VAC 1AD11N4005D31N4005+ C45+220

- Page 572:

270 SIGNAL SOURCES FOR SIMULATION,

- Page 576:

272 SIGNAL SOURCES FOR SIMULATION,

- Page 580:

274 SIGNAL SOURCES FOR SIMULATION,

- Page 584:

276 SIGNAL SOURCES FOR SIMULATION,

- Page 588:

278 SIGNAL SOURCES FOR SIMULATION,

- Page 592:

280 SIGNAL SOURCES FOR SIMULATION,

- Page 596:

C791uFR112Z_SIG_OUTZ Amplitude~0-50

- Page 600:

284 SIGNAL SOURCES FOR SIMULATION,

- Page 604:

286 SIGNAL SOURCES FOR SIMULATION,

- Page 608:

288 SIGNAL SOURCES FOR SIMULATION,

- Page 612:

290 SIGNAL SOURCES FOR SIMULATION,

- Page 616:

292 SIGNAL SOURCES FOR SIMULATION,

- Page 620:

294Figure 6.31 A potentiostat-galva

- Page 624:

296 SIGNAL SOURCES FOR SIMULATION,

- Page 628:

298 SIGNAL SOURCES FOR SIMULATION,

- Page 632:

300 SIGNAL SOURCES FOR SIMULATION,

- Page 636:

302 SIGNAL SOURCES FOR SIMULATION,

- Page 642:

7STIMULATION OF EXCITABLE TISSUESAn

- Page 646:

STIMULATION OF EXCITABLE TISSUES 30

- Page 650:

EXTRACELLULAR STIMULATION 309membra

- Page 654:

CLINICAL USES OF ELECTRICAL STIMULA

- Page 658:

9. Control of Parkinsonian tremor.

- Page 662:

TABLE 7.1(Continued)CLINICAL USES O

- Page 666:

DIRECT STIMULATION OF NERVE AND MUS

- Page 670:

DIRECT STIMULATION OF NERVE AND MUS

- Page 674:

DIRECT STIMULATION OF NERVE AND MUS

- Page 678:

ELECTRODE 1ELECTRODE 2I_OUTR3+15V_S

- Page 682:

DIRECT STIMULATION OF NERVE AND MUS

- Page 686:

DIRECT STIMULATION OF NERVE AND MUS

- Page 690:

DIRECT STIMULATION OF NERVE AND MUS

- Page 694:

DIRECT STIMULATION OF NERVE AND MUS

- Page 698:

DIRECT STIMULATION OF NERVE AND MUS

- Page 702:

WAVEFORM:CLOSED = MONOPHASICOPEN =

- Page 706:

DIRECT STIMULATION OF NERVE AND MUS

- Page 710:

BT1 BT2 BT3 BT41.5V1.5V1.5V1.5VSW1P

- Page 714:

DIRECT STIMULATION OF NERVE AND MUS

- Page 718:

ELECTRODE 3BODY PARTTO BESTIMULATED

- Page 722:

• Cardiac demand pacemakers that

- Page 726:

MAGNETIC STIMULATION 347trast, a ma

- Page 730:

SCR1ST330S16P0L1COILEXTREME DANGER!

- Page 734:

MAGNETIC STIMULATION 351• TOFF: t

- Page 738:

MAGNETIC STIMULATION 353+ -d/dtCOIL

- Page 742:

MAGNETIC STIMULATION 355tube cap. A

- Page 746:

OTHER CLINICAL APPLICATIONS OF ELEC

- Page 750:

OTHER CLINICAL APPLICATIONS OF ELEC

- Page 754:

OTHER CLINICAL APPLICATIONS OF ELEC

- Page 758:

OTHER CLINICAL APPLICATIONS OF ELEC

- Page 762:

OTHER CLINICAL APPLICATIONS OF ELEC

- Page 766:

Hodgkin, A. L., and A. F. Huxley, A

- Page 770:

8CARDIAC PACING AND DEFIBRILLATIONW

- Page 774:

BRADYARRHYTHMIAS 371As a result, on

- Page 778:

THE FIRST PACEMAKERS 373designed in

- Page 782:

Figure 8.4 The output of a PSpice s

- Page 786:

THE FIRST PACEMAKERS 377V SenseA Se

- Page 790:

Pacing Mode This parameter selects

- Page 794:

EXTERNAL VVI PACEMAKER 381EXTERNAL

- Page 798:

Figure 8.11 presents the schematic

- Page 802:

VDDV+AnodeACTI VE_DISCHARGEQ1BSS84R

- Page 806:

EXTERNAL VVI PACEMAKER 387TimeStamp

- Page 810:

EXTERNAL VVI PACEMAKER 389}}default

- Page 814:

SOFTWARE TESTING 391Of course, safe

- Page 818:

IMPEDANCE TECHNIQUE 393contraction)

- Page 822:

IMPEDANCE TECHNIQUE 395

- Page 826:

IMPEDANCE TECHNIQUE 397C110.1uFR205

- Page 830:

DEMOD_OUT+15Viso-15VisoINPUTJ5SMC39

- Page 834:

INTRACARDIAC IMPEDANCE SENSOR 401Le

- Page 838:

INTRACARDIAC IMPEDANCE SENSOR 403At

- Page 842:

INTRACARDIAC IMPEDANCE SENSOR 405Fi

- Page 846:

VENTRICULAR TACHYARRHYTHMIAS 407Tim

- Page 850:

1.61.41.2Output Voltage10.80.60.4DV

- Page 854:

VENTRICULAR TACHYARRHYTHMIAS 411Imp

- Page 858:

DEFIBRILLATION 413stimulus waveform

- Page 862:

SW5Safety InterlockF12AF20.25ASW1Po

- Page 866:

SHOCK BOX PROTOTYPE 417defibrillati

- Page 870:

SHOCK BOX PROTOTYPE 419Figure 8.34

- Page 874:

Figure 8.36 Interconnection diagram

- Page 878:

SHOCK BOX PROTOTYPE 423In operation

- Page 882:

SHOCK BOX PROTOTYPE 425markets and

- Page 886:

Figure 8.40 A H-bridge switch confi

- Page 890:

SHOCK BOX PROTOTYPE 429V_CAP_OUTR56

- Page 894:

SHOCK BOX PROTOTYPE 431onboard the

- Page 898:

SHOCK BOX PROTOTYPE 433+12_VBATC791

- Page 902:

SHOCK BOX PROTOTYPE 435value by the

- Page 906:

CARDIAC FIBRILLATOR 4373. Every 1 s

- Page 910:

CONCLUDING REMARKS 439+9VS1R1IC15CO

- Page 914:

EPILOGUEOut of clutter, find simpli

- Page 918:

PATH THROUGH THE FDA 443intended us

- Page 922:

the industry is undergoing profound

- Page 926:

APPENDIX ASOURCES FOR MATERIALS AND

- Page 930:

SOURCES FOR MATERIALS AND COMPONENT

- Page 934:

APPENDIX BFTP SITE CONTENTftp://ftp

- Page 938:

FTP SITE CONTENT 453• LPT8FAST.BA

- Page 942:

FTP SITE CONTENT 455Folder: Redistr

- Page 948:

458 INDEXCentro de Construccion de

- Page 952:

460 INDEXPacemaker(s) (Continued)pu