Annual report 2011 - Trelleborg

Annual report 2011 - Trelleborg

Annual report 2011 - Trelleborg

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TRELLEBORG & POLYMERS<br />

SEAL<br />

DAMP<br />

PROTECT<br />

By sealing, damping and protecting, we enable our customers to evolve<br />

The modern-day industrial and information society would not be possible without polymer material,<br />

or rubber and plastics as they are commonly known. All of the machines, tools and accessories that<br />

make up our everyday lives need sealing, damping and protecting using a material that is durable,<br />

elastic and tough. And it is precisely this technology that <strong>Trelleborg</strong> has mastered better than others,<br />

possessing know-how that is valued highly in relation to cost. For the customer, it is the difference<br />

between products that work or don’t work. <strong>Trelleborg</strong>’s polymer and applications know-how enables the<br />

customer to take the next step and to identify new, innovative solutions to address future challenges.<br />

16 <strong>Annual</strong> Report <strong>2011</strong> <strong>Trelleborg</strong> AB<br />

About polymers<br />

Polymers consist of long chains of molecules<br />

that form the building blocks in rubber<br />

and plastics. Rubber is composed of polymeric<br />

hydrocarbons. While natural rubber has only one<br />

chemical variant, there are 20 or more chemical<br />

variants of synthetic rubber.<br />

About rubber<br />

and its processes<br />

Rubber consists of the elements carbon and<br />

hydrogen. Treated rubber is elastic, water-repellant,<br />

moldable, and suppresses both noise and vibrations.<br />

Natural rubber is produced from the rubber tree (Hevea<br />

Brasiliensis). Synthetic rubber is produced chemically,<br />

usually from petroleum (oil). Untreated natural rubber<br />

cracks if it is too cold and becomes viscous if it is too<br />

warm. By adding sulfur, the rubber becomes elastic.<br />

Vulcanization is the basis of modern rubber’s almost<br />

infi nite application ppossibilities.<br />

The customer places demands...<br />

Customers demand genuine material expertise in the<br />

fi eld of polymer technology and solid engineering<br />

know-how regarding their products and manufacturing<br />

processes. They require understanding of what they<br />

aim to achieve in the next stage of their development,<br />

both technologically and commercially. In short, they<br />

want to know how sealing, damping and protecting can<br />

enhance the attractiveness of their products and solutions<br />

in relation to their own markets and customers.<br />

<strong>Trelleborg</strong> has accumulated and delivered this expertise<br />

for more than 100 years.<br />

…and <strong>Trelleborg</strong> has the expertise<br />

<strong>Trelleborg</strong>’s customer-centric development ensures that<br />

our engineers take a commercial approach to their<br />

work. This requires them not only to focus on more<br />

than product development alone, but also to provide<br />

advice on how manufacturing and processes can be<br />

streamlined through insight into production solutions,<br />

systemized thinking and services. <strong>Trelleborg</strong> offers this<br />

broad and deep expertise on a global scale, taking into<br />

consideration the unique individual customer needs<br />

that exist in various industries and markets.<br />

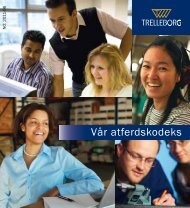

The rubber band is an everyday<br />

example of the elasticity of rubber.