Comparison of 9.5 mm SuperPave and Marshall Wearing I Mixes in ...

Comparison of 9.5 mm SuperPave and Marshall Wearing I Mixes in ...

Comparison of 9.5 mm SuperPave and Marshall Wearing I Mixes in ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

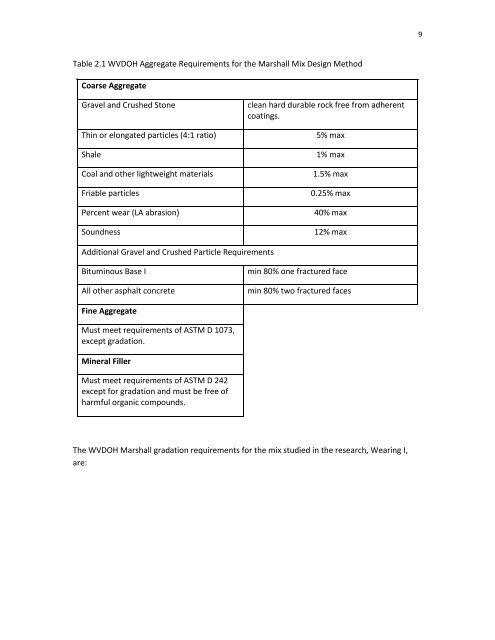

9Table 2.1 WVDOH Aggregate Requirements for the <strong>Marshall</strong> Mix Design MethodCoarse AggregateGravel <strong>and</strong> Crushed StoneTh<strong>in</strong> or elongated particles (4:1 ratio)ShaleCoal <strong>and</strong> other lightweight materialsFriable particlesPercent wear (LA abrasion)Soundnessclean hard durable rock free from adherentcoat<strong>in</strong>gs.5% max1% max1.5% max0.25% max40% max12% maxAdditional Gravel <strong>and</strong> Crushed Particle RequirementsBitum<strong>in</strong>ous Base IAll other asphalt concretem<strong>in</strong> 80% one fractured facem<strong>in</strong> 80% two fractured facesF<strong>in</strong>e AggregateMust meet requirements <strong>of</strong> ASTM D 1073,except gradation.M<strong>in</strong>eral FillerMust meet requirements <strong>of</strong> ASTM D 242except for gradation <strong>and</strong> must be free <strong>of</strong>harmful organic compounds.The WVDOH <strong>Marshall</strong> gradation requirements for the mix studied <strong>in</strong> the research, <strong>Wear<strong>in</strong>g</strong> I,are: