Comparison of 9.5 mm SuperPave and Marshall Wearing I Mixes in ...

Comparison of 9.5 mm SuperPave and Marshall Wearing I Mixes in ...

Comparison of 9.5 mm SuperPave and Marshall Wearing I Mixes in ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

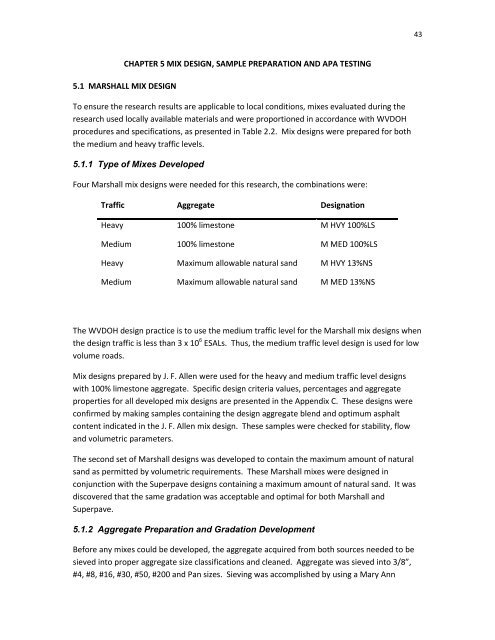

43CHAPTER 5 MIX DESIGN, SAMPLE PREPARATION AND APA TESTING5.1 MARSHALL MIX DESIGNTo ensure the research results are applicable to local conditions, mixes evaluated dur<strong>in</strong>g theresearch used locally available materials <strong>and</strong> were proportioned <strong>in</strong> accordance with WVDOHprocedures <strong>and</strong> specifications, as presented <strong>in</strong> Table 2.2. Mix designs were prepared for boththe medium <strong>and</strong> heavy traffic levels.5.1.1 Type <strong>of</strong> <strong>Mixes</strong> DevelopedFour <strong>Marshall</strong> mix designs were needed for this research, the comb<strong>in</strong>ations were:Traffic Aggregate DesignationHeavy 100% limestone M HVY 100%LSMedium 100% limestone M MED 100%LSHeavy Maximum allowable natural s<strong>and</strong> M HVY 13%NSMedium Maximum allowable natural s<strong>and</strong> M MED 13%NSThe WVDOH design practice is to use the medium traffic level for the <strong>Marshall</strong> mix designs whenthe design traffic is less than 3 x 10 6 ESALs. Thus, the medium traffic level design is used for lowvolume roads.Mix designs prepared by J. F. Allen were used for the heavy <strong>and</strong> medium traffic level designswith 100% limestone aggregate. Specific design criteria values, percentages <strong>and</strong> aggregateproperties for all developed mix designs are presented <strong>in</strong> the Appendix C. These designs wereconfirmed by mak<strong>in</strong>g samples conta<strong>in</strong><strong>in</strong>g the design aggregate blend <strong>and</strong> optimum asphaltcontent <strong>in</strong>dicated <strong>in</strong> the J. F. Allen mix design. These samples were checked for stability, flow<strong>and</strong> volumetric parameters.The second set <strong>of</strong> <strong>Marshall</strong> designs was developed to conta<strong>in</strong> the maximum amount <strong>of</strong> naturals<strong>and</strong> as permitted by volumetric requirements. These <strong>Marshall</strong> mixes were designed <strong>in</strong>conjunction with the Superpave designs conta<strong>in</strong><strong>in</strong>g a maximum amount <strong>of</strong> natural s<strong>and</strong>. It wasdiscovered that the same gradation was acceptable <strong>and</strong> optimal for both <strong>Marshall</strong> <strong>and</strong>Superpave.5.1.2 Aggregate Preparation <strong>and</strong> Gradation DevelopmentBefore any mixes could be developed, the aggregate acquired from both sources needed to besieved <strong>in</strong>to proper aggregate size classifications <strong>and</strong> cleaned. Aggregate was sieved <strong>in</strong>to 3/8”,#4, #8, #16, #30, #50, #200 <strong>and</strong> Pan sizes. Siev<strong>in</strong>g was accomplished by us<strong>in</strong>g a Mary Ann