lEidENSCHaFt - Storck Bicycle GmbH

lEidENSCHaFt - Storck Bicycle GmbH

lEidENSCHaFt - Storck Bicycle GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

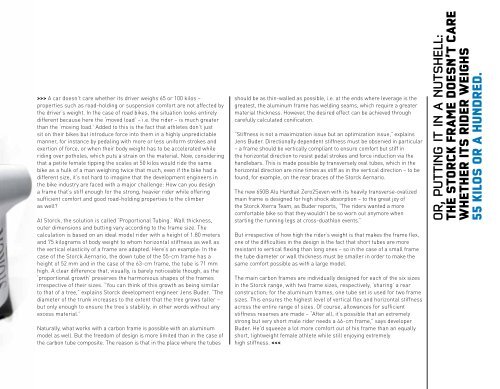

A car doesn’t care whether its driver weighs 65 or 100 kilos –properties such as road-holding or suspension comfort are not affected bythe driver’s weight. In the case of road bikes, the situation looks entirelydifferent because here the ‘moved load’ – i.e. the rider – is much greaterthan the ‘moving load.’ Added to this is the fact that athletes don’t justsit on their bikes but introduce force into them in a highly unpredictablemanner, for instance by pedaling with more or less uniform strokes andexertion of force, or when their body weight has to be accelerated whileriding over potholes, which puts a strain on the material. Now, consideringthat a petite female tipping the scales at 50 kilos would ride the samebike as a hulk of a man weighing twice that much, even if the bike had adifferent size, it’s not hard to imagine that the development engineers inthe bike industry are faced with a major challenge: How can you designa frame that’s stiff enough for the strong, heavier rider while offeringsufficient comfort and good road-holding properties to the climberas well?At <strong>Storck</strong>, the solution is called ‘Proportional Tubing.’ Wall thickness,outer dimensions and butting vary according to the frame size. Thecalculation is based on an ideal model rider with a height of 1.80 metersand 75 kilograms of body weight to whom horizontal stiffness as well asthe vertical elasticity of a frame are adapted. Here’s an example: In thecase of the <strong>Storck</strong> Aernario, the down tube of the 55-cm frame has aheight of 52 mm and in the case of the 63-cm frame, the tube is 71 mmhigh. A clear difference that, visually, is barely noticeable though, as the‘proportional growth’ preserves the harmonious shapes of the framesirrespective of their sizes. “You can think of this growth as being similarto that of a tree,” explains <strong>Storck</strong> development engineer Jens Buder. “Thediameter of the trunk increases to the extent that the tree grows taller –but only enough to ensure the tree’s stability, in other words without anyexcess material.”Naturally, what works with a carbon frame is possible with an aluminummodel as well. But the freedom of design is more limited than in the case ofthe carbon tube composite. The reason is that in the place where the tubesshould be as thin-walled as possible, i.e. at the ends where leverage is thegreatest, the aluminum frame has welding seams, which require a greatermaterial thickness. However, the desired effect can be achieved throughcarefully calculated conification.“Stiffness is not a maximization issue but an optimization issue,” explainsJens Buder. Directionally dependent stiffness must be observed in particular– a frame should be vertically compliant to ensure comfort but stiff inthe horizontal direction to resist pedal strokes and force induction via thehandlebars. This is made possible by transversely oval tubes, which in thehorizontal direction are nine times as stiff as in the vertical direction – to befound, for example, on the rear braces of the <strong>Storck</strong> Aernario.The new 650B Alu Hardtail Zero2Seven with its heavily transverse-ovalizedmain frame is designed for high shock absorption – to the great joy ofthe <strong>Storck</strong> Xterra Team, as Buder reports, “The riders wanted a morecomfortable bike so that they wouldn’t be so worn out anymore whenstarting the running legs at cross-duathlon events.”But irrespective of how high the rider’s weight is that makes the frame flex,one of the difficulties in the design is the fact that short tubes are moreresistant to vertical flexing than long ones – so in the case of a small framethe tube diameter or wall thickness must be smaller in order to make thesame comfort possible as with a large model.The main carbon frames are individually designed for each of the six sizesin the <strong>Storck</strong> range, with two frame sizes, respectively, ‘sharing’ a rearconstruction; for the aluminum frames, one tube set is used for two framesizes. This ensures the highest level of vertical flex and horizontal stiffnessacross the entire range of sizes. Of course, allowances for sufficientstiffness reserves are made – “After all, it’s possible that an extremelystrong but very short male rider needs a 46-cm frame,” says developerBuder. He’d squeeze a lot more comfort out of his frame than an equallyshort, lightweight female athlete while still enjoying extremelyhigh stiffness.