Operations Manual

Download - BAUER-Pileco

Download - BAUER-Pileco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

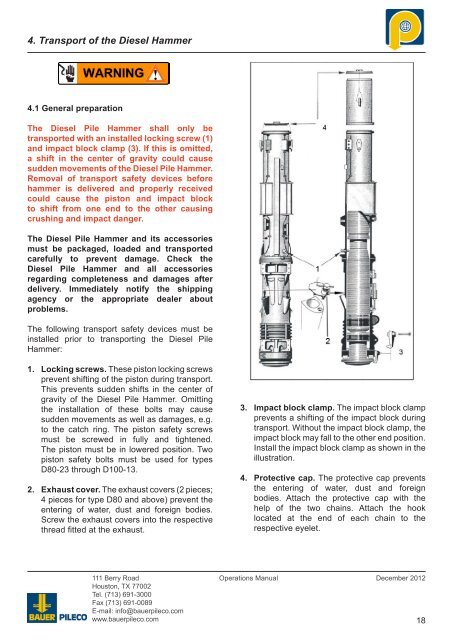

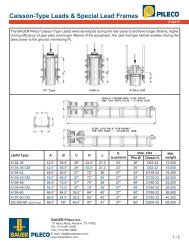

4. Transport of the Diesel Hammer<br />

4.1 General preparation<br />

The Diesel Pile Hammer shall only be<br />

transported with an installed locking screw (1)<br />

and impact block clamp (3). If this is omitted,<br />

a shift in the center of gravity could cause<br />

sudden movements of the Diesel Pile Hammer.<br />

Removal of transport safety devices before<br />

hammer is delivered and properly received<br />

could cause the piston and impact block<br />

to shift from one end to the other causing<br />

crushing and impact danger.<br />

The Diesel Pile Hammer and its accessories<br />

must be packaged, loaded and transported<br />

carefully to prevent damage. Check the<br />

Diesel Pile Hammer and all accessories<br />

regarding completeness and damages after<br />

delivery. Immediately notify the shipping<br />

agency or the appropriate dealer about<br />

problems.<br />

The following transport safety devices must be<br />

installed prior to transporting the Diesel Pile<br />

Hammer:<br />

1. Locking screws. These piston locking screws<br />

prevent shifting of the piston during transport.<br />

This prevents sudden shifts in the center of<br />

gravity of the Diesel Pile Hammer. Omitting<br />

the installation of these bolts may cause<br />

sudden movements as well as damages, e.g.<br />

to the catch ring. The piston safety screws<br />

must be screwed in fully and tightened.<br />

The piston must be in lowered position. Two<br />

piston safety bolts must be used for types<br />

D80-23 through D100-13.<br />

2. Exhaust cover. The exhaust covers (2 pieces;<br />

4 pieces for type D80 and above) prevent the<br />

entering of water, dust and foreign bodies.<br />

Screw the exhaust covers into the respective<br />

thread fitted at the exhaust.<br />

3. Impact block clamp. The impact block clamp<br />

prevents a shifting of the impact block during<br />

transport. Without the impact block clamp, the<br />

impact block may fall to the other end position.<br />

Install the impact block clamp as shown in the<br />

illustration.<br />

4. Protective cap. The protective cap prevents<br />

the entering of water, dust and foreign<br />

bodies. Attach the protective cap with the<br />

help of the two chains. Attach the hook<br />

located at the end of each chain to the<br />

respective eyelet.<br />

111 Berry Road<br />

Houston, TX 77002<br />

Tel. (713) 691-3000<br />

Fax (713) 691-0089<br />

E-mail: info@bauerpileco.com<br />

www.bauerpileco.com<br />

<strong>Operations</strong> <strong>Manual</strong> December 2012<br />

18