m return - mbm-Service GmbH

m return - mbm-Service GmbH

m return - mbm-Service GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

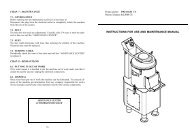

3. ELECTRICAL CONNECTION<br />

• The appliance must be connected to the mains power supply<br />

in compliance with current regulations.<br />

• Before connecting the appliance to the mains supply, make<br />

sure that the voltage and frequency shown on the appliance<br />

rating plate correspond with that of the power supply.<br />

• The appliance must be permanently connected to the mains<br />

power supply with an H05 RN-F type cable. The power supply<br />

cable must be protected by a metal or rigid plastic tube. If the<br />

appliance is connected by way of an existing lead, do not insert<br />

the installation tube in the appliance and make sure the tube<br />

has no sharp edges.<br />

• A safety cutout switch of suitable capacity with a contact<br />

breaking distance of at least 3 mm must be fitted upstream of<br />

the appliance.<br />

This cutout switch must be installed near the appliance in the<br />

permanent electrical system of the premises.<br />

• The appliance must be suitably earthed. The earthing conductor<br />

must therefore be connected to the terminal marked G on<br />

the connection terminal board. The appliance must also be<br />

connected to an equipotential system.<br />

This connection is made using the stop screw marked E<br />

located on the outside of the appliance near the power cable<br />

inlet.<br />

The equipotential wire must have a minimum cross-section of<br />

10 mm 2 .<br />

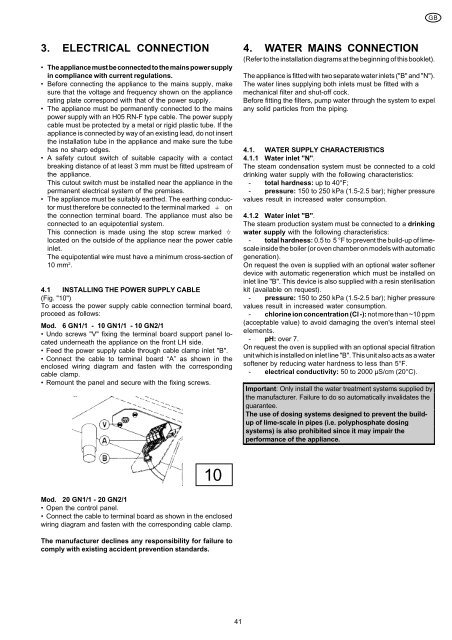

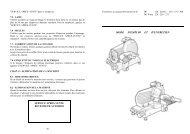

4.1 INSTALLING THE POWER SUPPLY CABLE<br />

(Fig. "10")<br />

To access the power supply cable connection terminal board,<br />

proceed as follows:<br />

Mod. 6 GN1/1 - 10 GN1/1 - 10 GN2/1<br />

• Undo screws "V" fixing the terminal board support panel located<br />

underneath the appliance on the front LH side.<br />

• Feed the power supply cable through cable clamp inlet "B".<br />

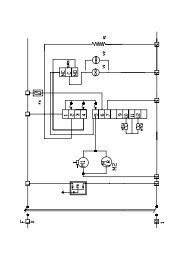

• Connect the cable to terminal board “A” as shown in the<br />

enclosed wiring diagram and fasten with the corresponding<br />

cable clamp.<br />

• Remount the panel and secure with the fixing screws.<br />

10<br />

Mod. 20 GN1/1 - 20 GN2/1<br />

• Open the control panel.<br />

• Connect the cable to terminal board as shown in the enclosed<br />

wiring diagram and fasten with the corresponding cable clamp.<br />

The manufacturer declines any responsibility for failure to<br />

comply with existing accident prevention standards.<br />

41<br />

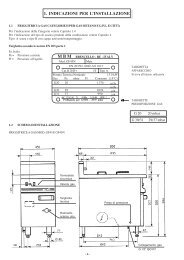

4. WATER MAINS CONNECTION<br />

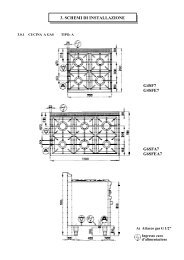

(Refer to the installation diagrams at the beginning of this booklet).<br />

The appliance is fitted with two separate water inlets ("B" and "N").<br />

The water lines supplying both inlets must be fitted with a<br />

mechanical filter and shut-off cock.<br />

Before fitting the filters, pump water through the system to expel<br />

any solid particles from the piping.<br />

4.1. WATER SUPPLY CHARACTERISTICS<br />

4.1.1 Water inlet "N".<br />

The steam condensation system must be connected to a cold<br />

drinking water supply with the following characteristics:<br />

- total hardness: up to 40°F;<br />

- pressure: 150 to 250 kPa (1.5-2.5 bar); higher pressure<br />

values result in increased water consumption.<br />

4.1.2 Water inlet "B".<br />

The steam production system must be connected to a drinking<br />

water supply with the following characteristics:<br />

- total hardness: 0.5 to 5 °F to prevent the build-up of limescale<br />

inside the boiler (or oven chamber on models with automatic<br />

generation).<br />

On request the oven is supplied with an optional water softener<br />

device with automatic regeneration which must be installed on<br />

inlet line "B". This device is also supplied with a resin sterilisation<br />

kit (available on request).<br />

- pressure: 150 to 250 kPa (1.5-2.5 bar); higher pressure<br />

values result in increased water consumption.<br />

- chlorine ion concentration (Cl -): not more than ~10 ppm<br />

(acceptable value) to avoid damaging the oven's internal steel<br />

elements.<br />

- pH: over 7.<br />

On request the oven is supplied with an optional special filtration<br />

unit which is installed on inlet line "B". This unit also acts as a water<br />

softener by reducing water hardness to less than 5°F.<br />

- electrical conductivity: 50 to 2000 µS/cm (20°C).<br />

Important: Only install the water treatment systems supplied by<br />

the manufacturer. Failure to do so automatically invalidates the<br />

guarantee.<br />

The use of dosing systems designed to prevent the buildup<br />

of lime-scale in pipes (i.e. polyphosphate dosing<br />

systems) is also prohibited since it may impair the<br />

performance of the appliance.<br />

GB