m return - mbm-Service GmbH

m return - mbm-Service GmbH

m return - mbm-Service GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

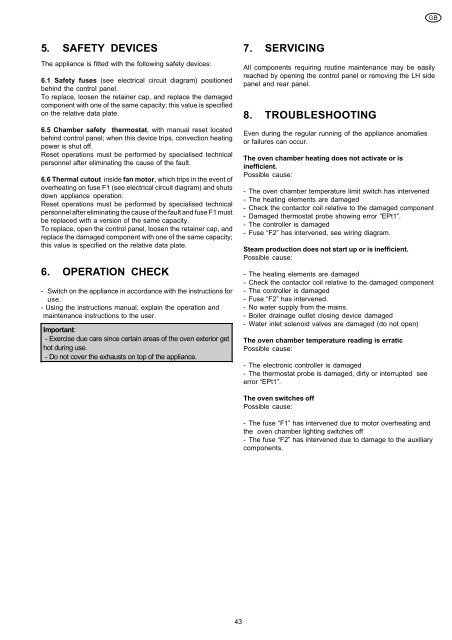

5. SAFETY DEVICES<br />

The appliance is fitted with the following safety devices:<br />

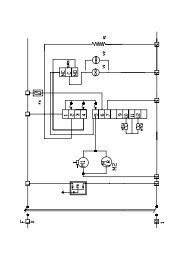

6.1 Safety fuses (see electrical circuit diagram) positioned<br />

behind the control panel.<br />

To replace, loosen the retainer cap, and replace the damaged<br />

component with one of the same capacity; this value is specified<br />

on the relative data plate.<br />

6.5 Chamber safety thermostat, with manual reset located<br />

behind control panel; when this device trips, convection heating<br />

power is shut off.<br />

Reset operations must be performed by specialised technical<br />

personnel after eliminating the cause of the fault.<br />

6.6 Thermal cutout inside fan motor, which trips in the event of<br />

overheating on fuse F1 (see electrical circuit diagram) and shuts<br />

down appliance operation.<br />

Reset operations must be performed by specialised technical<br />

personnel after eliminating the cause of the fault and fuse F1 must<br />

be replaced with a version of the same capacity.<br />

To replace, open the control panel, loosen the retainer cap, and<br />

replace the damaged component with one of the same capacity;<br />

this value is specified on the relative data plate.<br />

6. OPERATION CHECK<br />

- Switch on the appliance in accordance with the instructions for<br />

use.<br />

- Using the instructions manual, explain the operation and<br />

maintenance instructions to the user.<br />

Important:<br />

- Exercise due care since certain areas of the oven exterior get<br />

hot during use.<br />

- Do not cover the exhausts on top of the appliance.<br />

43<br />

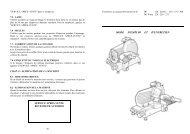

7. SERVICING<br />

All components requiring routine maintenance may be easily<br />

reached by opening the control panel or removing the LH side<br />

panel and rear panel.<br />

8. TROUBLESHOOTING<br />

Even during the regular running of the appliance anomalies<br />

or failures can occur.<br />

The oven chamber heating does not activate or is<br />

inefficient.<br />

Possible cause:<br />

- The oven chamber temperature limit switch has intervened<br />

- The heating elements are damaged<br />

- Check the contactor coil relative to the damaged component<br />

- Damaged thermostat probe showing error “EPt1”.<br />

- The controller is damaged<br />

- Fuse “F2” has intervened, see wiring diagram.<br />

Steam production does not start up or is inefficient.<br />

Possible cause:<br />

- The heating elements are damaged<br />

- Check the contactor coil relative to the damaged component<br />

- The controller is damaged<br />

- Fuse “F2” has intervened.<br />

- No water supply from the mains.<br />

- Boiler drainage outlet closing device damaged<br />

- Water inlet solenoid valves are damaged (do not open)<br />

The oven chamber temperature reading is erratic<br />

Possible cause:<br />

- The electronic controller is damaged<br />

- The thermostat probe is damaged, dirty or interrupted see<br />

error “EPt1”.<br />

The oven switches off<br />

Possible cause:<br />

- The fuse “F1” has intervened due to motor overheating and<br />

the oven chamber lighting switches off<br />

- The fuse “F2” has intervened due to damage to the auxiliary<br />

components.<br />

GB