Smart Industry 1/2019

Smart Industry 1/2019 - The IoT Business Magazine - powered by Avnet Silica

Smart Industry 1/2019 - The IoT Business Magazine - powered by Avnet Silica

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

These days you read a lot<br />

about autonomous cars but<br />

you rarely see any. Of course,<br />

there are assisting systems<br />

that make steering a lot easier under<br />

certain conditions – but when the<br />

driving environment becomes more<br />

complex, the systems are less reliable.<br />

It will probably still take a while until<br />

you just have to climb into a car and<br />

tell it where to take you.<br />

There are other means of transport,<br />

of course, and many of them move in<br />

surroundings that seem a lot easier to<br />

handle. So what’s new on the tracks,<br />

on the water, and in the air?<br />

All Aboard the Auto-Train<br />

With increasing traffic jams and rising<br />

awareness of the environmental impact<br />

of cars, many people are switching<br />

to public transport. The Dutch rail<br />

network, for example, projected that<br />

the number of passengers would increase<br />

by at least 45 percent by 2030.<br />

Freight volumes are also rising and<br />

source ©: prorail.nl<br />

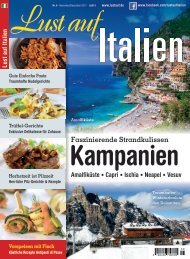

Best of Both Worlds<br />

The Dutch railway<br />

company ProRail is<br />

experimenting with<br />

semiautonomous<br />

trains built by Arriva<br />

and Stadler. Stopping<br />

and starting is<br />

automated, but a<br />

driver handles the<br />

doors and intervenes<br />

in case of an emergency.<br />

Getting the Ore Out<br />

The Australian mining<br />

company Rio Tinto<br />

hauls up to 28,000<br />

tons of iron ore a day<br />

via a 2.4-kilometer-long<br />

driverless train aptly<br />

christened “AutoHaul.”<br />

the Dutch railway company ProRail is<br />

searching for ways to make better use<br />

of the existing infrastructure.<br />

“There are so many trains on the grid<br />

that the distance between them is<br />

relatively short,” said Rick van der<br />

Mand, project manager of an autonomous<br />

driving experiment that ProRail<br />

carried out with partners Arriva and<br />

Stadler in March <strong>2019</strong>. “It’s so busy<br />

that congestion is never far away. Automation<br />

may prevent that.”<br />

In a week-long trial on the Groningen<br />

to Zuidhorn line, the group<br />

tested a modified railcar produced<br />

by Swiss manufacturer Stadler,<br />

undertaking a first run operating<br />

in Grade of Automation 2 (GoA 2)<br />

– semiautomatic train operation<br />

where starting and stopping is automated<br />

but a driver operates the<br />

doors, drives the train if needed,<br />

and handles emergencies. With a<br />

driver in attendance, the train made<br />

automated stops at Groningen,<br />

Hoogkerk, and Zuidhorn. ProRail<br />

hailed this as a success and is continuing<br />

the trial but the company is<br />

not yet ready to set a date on when<br />

the first autonomous trains will be<br />

in everyday operation.<br />

ATO (Automatic Train Operation) not<br />

only allows trains to operate more<br />

frequently at shorter headways and to<br />

stop more precisely but also improves<br />

energy consumption through the optimization<br />

of acceleration, speed, and<br />

braking. ProRail is also investigating<br />

the use of ATO on freight trains and, in<br />

conjunction with Rotterdam Rail Feeding<br />

and Alstom, they ran a modified locomotive<br />

on the Betuwe route in 2018.<br />

A more impressive example of an<br />

autonomous freight train is already<br />

operating steadily on the other side<br />

of the world: in the Pilbara region of<br />

Western Australia in July 2018, mining<br />

company Rio Tinto delivered iron ore<br />

by autonomous train for the first time.<br />

The AutoHaul project train consists<br />

of three locomotives, is 2.4 kilometers<br />

long, and can carry up to 28,000<br />

tons of iron ore. It travels more than<br />

280 kilometers north from the mining<br />

operations in Tom Price to the port of<br />

Cape Lambert.<br />

The train operators are located in the<br />

Rio Tinto Operations Centre in Perth –<br />

which is more than 1,300 kilometers<br />

south of the mines. “There is a train<br />

controller at the Operations Centre in<br />

Perth who sets the route – but once it’s<br />

running the on-board computers<br />

59<br />

source ©: Rio Tinto