Prosthetic Arm Force Reducer Team 1 – Halliday's ... - Ohio University

Prosthetic Arm Force Reducer Team 1 – Halliday's ... - Ohio University

Prosthetic Arm Force Reducer Team 1 – Halliday's ... - Ohio University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

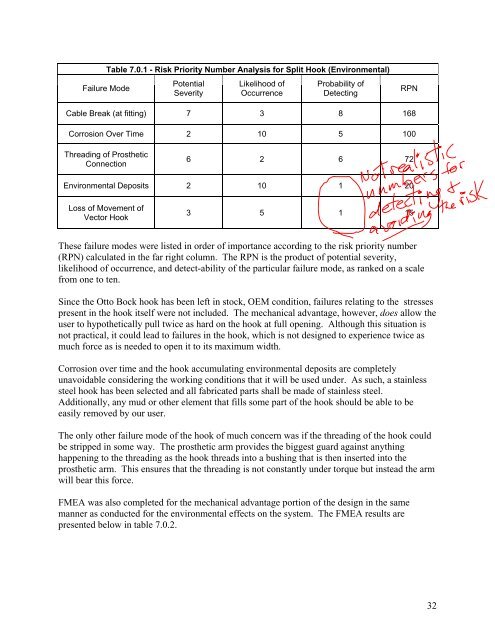

Failure Mode<br />

Table 7.0.1 - Risk Priority Number Analysis for Split Hook (Environmental)<br />

Potential<br />

Severity<br />

Likelihood of<br />

Occurrence<br />

Probability of<br />

Detecting<br />

Cable Break (at fitting) 7 3 8 168<br />

Corrosion Over Time 2 10 5 100<br />

Threading of <strong>Prosthetic</strong><br />

Connection<br />

RPN<br />

6 2 6 72<br />

Environmental Deposits 2 10 1 20<br />

Loss of Movement of<br />

Vector Hook<br />

3 5 1 15<br />

These failure modes were listed in order of importance according to the risk priority number<br />

(RPN) calculated in the far right column. The RPN is the product of potential severity,<br />

likelihood of occurrence, and detect-ability of the particular failure mode, as ranked on a scale<br />

from one to ten.<br />

Since the Otto Bock hook has been left in stock, OEM condition, failures relating to the stresses<br />

present in the hook itself were not included. The mechanical advantage, however, does allow the<br />

user to hypothetically pull twice as hard on the hook at full opening. Although this situation is<br />

not practical, it could lead to failures in the hook, which is not designed to experience twice as<br />

much force as is needed to open it to its maximum width.<br />

Corrosion over time and the hook accumulating environmental deposits are completely<br />

unavoidable considering the working conditions that it will be used under. As such, a stainless<br />

steel hook has been selected and all fabricated parts shall be made of stainless steel.<br />

Additionally, any mud or other element that fills some part of the hook should be able to be<br />

easily removed by our user.<br />

The only other failure mode of the hook of much concern was if the threading of the hook could<br />

be stripped in some way. The prosthetic arm provides the biggest guard against anything<br />

happening to the threading as the hook threads into a bushing that is then inserted into the<br />

prosthetic arm. This ensures that the threading is not constantly under torque but instead the arm<br />

will bear this force.<br />

FMEA was also completed for the mechanical advantage portion of the design in the same<br />

manner as conducted for the environmental effects on the system. The FMEA results are<br />

presented below in table 7.0.2.<br />

32