Prosthetic Arm Force Reducer Team 1 – Halliday's ... - Ohio University

Prosthetic Arm Force Reducer Team 1 – Halliday's ... - Ohio University

Prosthetic Arm Force Reducer Team 1 – Halliday's ... - Ohio University

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

attempting to create an attachment that could open and then hold the feed sack. Another<br />

suggestion he made was to attempt to put ourselves in the shoes of the person with a disability<br />

and spend the day trying to replicate the disability that is to be addressed. This would allow the<br />

team members to have first-hand experience with the particular disability. Other ideas he<br />

mentioned were excursion amplifiers, back harnesses, page turners, devices to help people get<br />

dressed and to feed themselves, home modifications, work site ergonomics, rural and farming<br />

work, computer adaptation, weight distribution, body position, and seating for people in to<br />

wheelchairs.<br />

After analyzing and debating the external research that was gathered, the decision was made to<br />

focus on the area of upper extremity loss with emphasis on agricultural solutions. Patent<br />

research was done to find solutions that might involve prosthetics or adaptations to equipment<br />

that farmers must use. In the area of prosthetics, emphasis was given to the fact that the arm<br />

would be used for physical labor and must be able to withstand and perform such heavy labor but<br />

yet reduce the amount of physical impact on his or her body.<br />

4.1 Benchmarking<br />

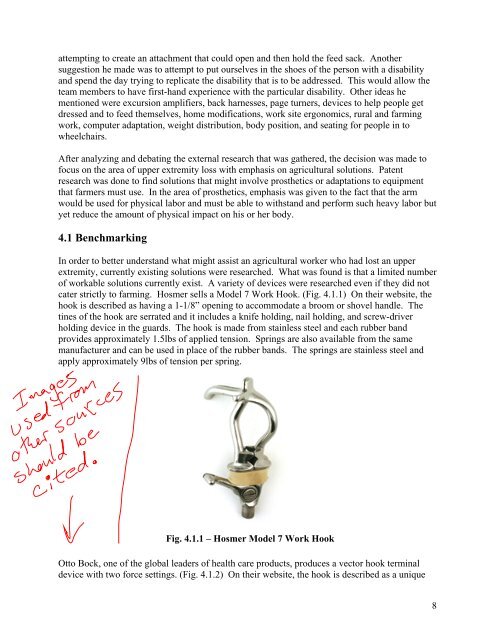

In order to better understand what might assist an agricultural worker who had lost an upper<br />

extremity, currently existing solutions were researched. What was found is that a limited number<br />

of workable solutions currently exist. A variety of devices were researched even if they did not<br />

cater strictly to farming. Hosmer sells a Model 7 Work Hook. (Fig. 4.1.1) On their website, the<br />

hook is described as having a 1-1/8” opening to accommodate a broom or shovel handle. The<br />

tines of the hook are serrated and it includes a knife holding, nail holding, and screw-driver<br />

holding device in the guards. The hook is made from stainless steel and each rubber band<br />

provides approximately 1.5lbs of applied tension. Springs are also available from the same<br />

manufacturer and can be used in place of the rubber bands. The springs are stainless steel and<br />

apply approximately 9lbs of tension per spring.<br />

Fig. 4.1.1 <strong>–</strong> Hosmer Model 7 Work Hook<br />

Otto Bock, one of the global leaders of health care products, produces a vector hook terminal<br />

device with two force settings. (Fig. 4.1.2) On their website, the hook is described as a unique<br />

8