Prosthetic Arm Force Reducer Team 1 – Halliday's ... - Ohio University

Prosthetic Arm Force Reducer Team 1 – Halliday's ... - Ohio University

Prosthetic Arm Force Reducer Team 1 – Halliday's ... - Ohio University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The rings are the most expensive part of the mechanical advantage system because they will be<br />

made out of a 2-1/2” diam. stainless steel pipe. The minimum length of stock for this pipe size is<br />

12’’ and as such a large amount of extra material had to be purchased. The high cost<br />

(approximately $73) is hard to justify for the construction of a single system, however this stock<br />

would be fine if multiple systems were to be constructed.<br />

A nylon pulley with a stainless steel housing was selected. This item cost around $20 and will<br />

require no additional modifications. The bearings were selected due to the flexibility of sizes<br />

available and the low cost. Ball bearings are approximately one-third the cost of rubberized<br />

wheels. The 1/4” diameter stock for the axles and spacers was very inexpensive at around $6 per<br />

12” length. All materials, with the exception of the nylon pulley, of the mechanical advantage<br />

system are stainless steel which makes any necessary welding possible and is good for corrosion<br />

7.0.7 Design Analysis<br />

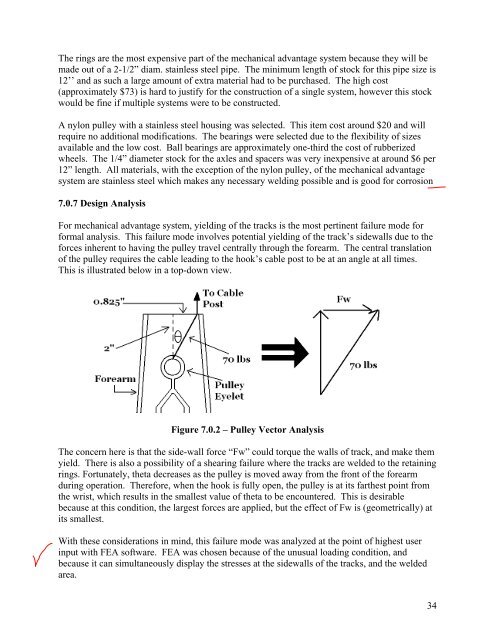

For mechanical advantage system, yielding of the tracks is the most pertinent failure mode for<br />

formal analysis. This failure mode involves potential yielding of the track’s sidewalls due to the<br />

forces inherent to having the pulley travel centrally through the forearm. The central translation<br />

of the pulley requires the cable leading to the hook’s cable post to be at an angle at all times.<br />

This is illustrated below in a top-down view.<br />

Figure 7.0.2 <strong>–</strong> Pulley Vector Analysis<br />

The concern here is that the side-wall force “Fw” could torque the walls of track, and make them<br />

yield. There is also a possibility of a shearing failure where the tracks are welded to the retaining<br />

rings. Fortunately, theta decreases as the pulley is moved away from the front of the forearm<br />

during operation. Therefore, when the hook is fully open, the pulley is at its farthest point from<br />

the wrist, which results in the smallest value of theta to be encountered. This is desirable<br />

because at this condition, the largest forces are applied, but the effect of Fw is (geometrically) at<br />

its smallest.<br />

With these considerations in mind, this failure mode was analyzed at the point of highest user<br />

input with FEA software. FEA was chosen because of the unusual loading condition, and<br />

because it can simultaneously display the stresses at the sidewalls of the tracks, and the welded<br />

area.<br />

34