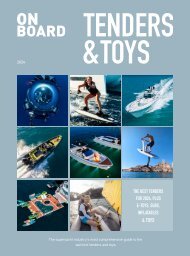

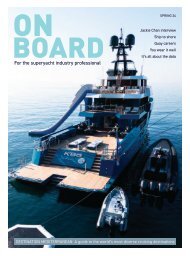

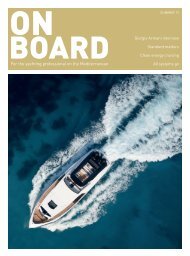

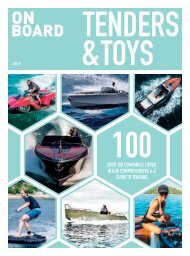

ONBOARD Magazine summer 2021

The magazine is published quarterly and is the only publication aimed purely at the superyacht professional on the Mediterranean. Produced here on the Côte d’Azur, ONBOARD is a B2B industry magazine with a consumer feel. Designed to be entertaining and informative in equal balance, ONBOARD is packed with varied articles on superyacht paint & coatings, crew training, essential refit services, crew uniforms, shipyards, the very best superyacht chase boats, product launches and features from leading industry experts on relevant superyacht matters. If you need to get your products and services in front of the right crew and industry buyers, then talk to us.

The magazine is published quarterly and is the only publication aimed purely at the superyacht professional on the Mediterranean. Produced here on the Côte d’Azur, ONBOARD is a B2B industry magazine with a consumer feel. Designed to be entertaining and informative in equal balance, ONBOARD is packed with varied articles on superyacht paint & coatings, crew training, essential refit services, crew uniforms, shipyards, the very best superyacht chase boats, product launches and features from leading industry experts on relevant superyacht matters.

If you need to get your products and services in front of the right crew and industry buyers, then talk to us.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ADVERTORIAL

FINDING THE HOT SPOT

Tony Dale discusses the uses of thermal imaging systems for the

prevention of yacht electrical outages and engine room fires

hot surfaces is a recipe for disaster in the

event of fuel system failure. The International

Convention for the Safety of Life at Sea

(SOLAS) states that vessel parts with

temperatures above 220°C that may be

impinged as a result of a fuel system failure

must be properly insulated. Likewise, hot

surfaces, electrical installations and other

sources of ignition must be screened and

suitably protected to avoid oil spray or oil

leakage onto them.

With a host of superyacht condition

monitoring systems available

today, thermal imaging plays a key

part in protecting owners’ and stakeholders’

investment, including crew safety. From

stabilised roof mounted systems turning

night into day to aid navigation, to portable

handheld thermal imagers aiding yacht rescue

teams to see through smoke-filled corridors

and inside cabins, or engineers tasked to

identify failing electrical equipment to prevent

blackouts and electrical fires. There is a

range of thermal imaging devices currently

on the market tailored to suit all yacht

needs and budgets.

In principle, all thermal imaging devices

do the same thing, they passively detect

infrared energy from a warm surface, and

create a usable image. In essence, energy

passes through an imager’s germanium

lens onto a micro-bolometer array and is

converted to electrical signals. An algorithm

processes the data and assigns a colour and

temperature value, for a qualified engineer

to analyse and interpret.

With experience in both the superyacht

industry and with major offshore energy

producers, Dale has been conducting

thermography inspections over the past

20 years in over 40 countries for their

annual maintenance inspections and warranty

purposes. It has become evident vessel

engineers tasked with performing routine

maintenance checks are becoming more

reliant on thermal imaging devices to identify

system deficiencies before an outage occurs.

Yacht fires are caused by three primary

reasons: electrical system failures,

machinery failure and/or human activities.

While the probability of fire occurrence is

low, the potential for electrical fires is high

due to the tens of thousands of connections

on-board.

Whereas motor layshafts may suffer bearing

fatigue and misalignment issues, each

revealed as heat; and engine rooms with

ill-fitting exhaust insulating wrap exposing

Regardless of the size or type of equipment on

board, yacht electro-mechanical systems are

vulnerable to the harsh marine environment,

oxidation, vibration, wear and service care,

(or lack of it). With yacht ownership changing

more frequently – (particularly in the <40m

yacht market) and differing maintenance

and running cost histories exacerbated by

a yacht’s age, everything leads towards the

need for additional effective maintenance and

service improvement measures, including

a thermal survey.

A regular well-planned maintenance regime is

designed to keep a yacht seaworthy. It is the

ISM Code that addresses the responsibilities

of the people who manage and operate yachts

over 500 gross tons. Stipulating the need

for maintenance procedures with regular

inspections to record non-conformities and

corrective activities undertaken. Guidelines

and marine notices published by the MCA

and Classification Societies all recognise the

benefits of additional inspections, particularly

the versatility of Thermographic Surveys for

regular and five yearly periodic survey use.

In summary, a Thermographic Survey is

non-invasive, cost-effective and timely,

meaning operational uptimes are maintained,

regardless of yacht size. Annual service

agreements using an accredited third-party

company ensures impartiality, insurance and

audit compliance. Drawing on industry best

practices, experts like Geo Therm Ltd are

capable and credible to thoroughly survey

a yacht’s electro-mechanical systems to

identify thermal deficiencies to prevent the

risk of blackouts, downtime, and fire.

For more details

Tel: +44 (0)1502 723 241

or visit www. geothermltd.co.uk

ONBOARD | SUMMER 2021 | 27