The Etymologies of Isidore of Seville - Pot-pourri

The Etymologies of Isidore of Seville - Pot-pourri

The Etymologies of Isidore of Seville - Pot-pourri

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

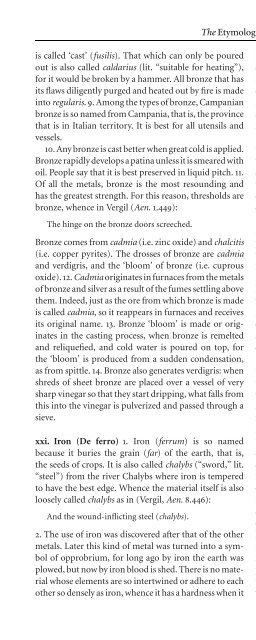

is called ‘cast’ (fusilis). That which can only be poured<br />

out is also called caldarius (lit. “suitable for heating”),<br />

for it would be broken by a hammer. All bronze that has<br />

its flaws diligently purged and heated out by fire is made<br />

into regularis. 9.Among the types <strong>of</strong> bronze, Campanian<br />

bronze is so named from Campania, that is, the province<br />

that is in Italian territory. It is best for all utensils and<br />

vessels.<br />

10.Any bronze is cast better when great cold is applied.<br />

Bronze rapidly develops a patina unless it is smeared with<br />

oil. People say that it is best preserved in liquid pitch. 11.<br />

Of all the metals, bronze is the most resounding and<br />

has the greatest strength. For this reason, thresholds are<br />

bronze, whenceinVergil(Aen. 1.449):<br />

<strong>The</strong> hinge on the bronze doors screeched.<br />

Bronze comes from cadmia (i.e. zinc oxide) and chalcitis<br />

(i.e. copper pyrites). <strong>The</strong> drosses <strong>of</strong> bronze are cadmia<br />

and verdigris, and the ‘bloom’ <strong>of</strong> bronze (i.e. cuprous<br />

oxide). 12. Cadmia originates in furnaces from the metals<br />

<strong>of</strong> bronze and silver as a result <strong>of</strong> the fumes settling above<br />

them. Indeed, just as the ore from which bronze is made<br />

is called cadmia,soitreappears in furnaces and receives<br />

its original name. 13. Bronze‘bloom’is made or originates<br />

in the casting process, when bronze is remelted<br />

and reliquefied, and cold water is poured on top, for<br />

the ‘bloom’ is produced from a sudden condensation,<br />

as from spittle. 14.Bronze also generates verdigris: when<br />

shreds <strong>of</strong> sheet bronze are placed over a vessel <strong>of</strong> very<br />

sharp vinegar so that they start dripping, what falls from<br />

this into the vinegar is pulverized and passed through a<br />

sieve.<br />

xxi. Iron (De ferro) 1. Iron (ferrum) is so named<br />

because it buries the grain (far) <strong>of</strong>the earth, that is,<br />

the seeds <strong>of</strong> crops. It is also called chalybs (“sword,” lit.<br />

“steel”) from the river Chalybs where iron is tempered<br />

to have the best edge. Whence the material itself is also<br />

loosely called chalybs as in (Vergil, Aen. 8.446):<br />

And the wound-inflicting steel (chalybs).<br />

2. <strong>The</strong>use <strong>of</strong> iron was discovered after that <strong>of</strong> the other<br />

metals. Later this kind <strong>of</strong> metal was turned into a symbol<br />

<strong>of</strong> opprobrium,forlongago by iron the earth was<br />

plowed, but now by iron blood is shed. <strong>The</strong>re is no material<br />

whose elements are so intertwined or adhere to each<br />

other so densely as iron, whence it has a hardness when it<br />

<strong>The</strong> <strong>Etymologies</strong> XVI.xx.9–xxi.7 331<br />

is cold. Iron mines are found almost everywhere, but <strong>of</strong><br />

all the kinds <strong>of</strong> iron, the prize is given to Seric (i.e. Chinese)<br />

iron. <strong>The</strong> Seres export this iron along with their<br />

cloth and animal skins. Second place goes to Parthian<br />

iron – none <strong>of</strong> the other kinds <strong>of</strong> iron are tempered to<br />

an edge from the pure metal, for a s<strong>of</strong>ter alloy is mixed<br />

in the others.<br />

3.<strong>The</strong>re are many differences in iron according to the<br />

type <strong>of</strong> its earthy element. <strong>The</strong> one type is s<strong>of</strong>t, close<br />

to lead, and suitable for use in wheels and nails, while<br />

another type is breakable and bronze-like, well suited for<br />

tilling the earth. Another type is good in short lengths<br />

only and for the nails in soldiers’ boots, and another is<br />

quickly vulnerable to rust. <strong>The</strong>se are all called strictura<br />

(lit. “a mass <strong>of</strong> wrought iron,” or “an iron bar”), a word<br />

not used for other metals, from ‘compressing’ (stringere,<br />

ppl. strictus), a term aptly applied. <strong>The</strong>re is a great difference<br />

in the types <strong>of</strong> water in which the glowing iron<br />

is plunged when it is tempered, such as the waters <strong>of</strong><br />

Bilbilis and Tirassona in Spain, and Como in Italy. 4.<br />

In sharpening iron, the edge is made finer by using oil,<br />

whence it is also customary for the more delicate iron<br />

implements to be tempered in oil, lest they be hardened<br />

by water to the point <strong>of</strong> fragility. Human blood<br />

avenges itself oniron,foritveryquickly forms rust on<br />

contact.<br />

Magnetic stone has an affinity with iron, for iron alone<br />

takes on the power <strong>of</strong> that stone and retains it for a long<br />

time. A certain architect in Alexandria built a temple<br />

vault from magnets, so that in it a statue made <strong>of</strong> iron<br />

might seem to hang in the air. Iron that has been in the<br />

fire is ruined unless it is hardened by hammering. When<br />

it has become red it is not suitable for hammering – not<br />

until it begins to get white. Iron smeared with vinegar or<br />

alum becomes similar to bronze. 5. <strong>The</strong>drosses <strong>of</strong> iron<br />

are rust and slag. Rust (robigo) isacorroding(rodere)<br />

flaw <strong>of</strong> iron, or <strong>of</strong> crops, as if the word were rodigo,with<br />

one letter changed. Also the word verdigris (aerugo) is<br />

from ‘eroding’ (erodere) –forverdigrisisaflawiniron<br />

so called from eroding – not from aerumentum (“bronze<br />

object”). 6. But slag is the residue and impurity that is<br />

heated out in the fire, and it is called slag (scoria)because<br />

it is ‘cast out’ (excutere)<strong>of</strong>iron.7.Ironwillbefree<strong>of</strong>rust<br />

if it is rubbed with white lead and gypsum and liquid<br />

pitch. Also, rust does not damage iron implements if<br />

they are smeared with deer marrow or white lead mixed<br />

with oil <strong>of</strong> roses.