FALL 2023

Distributor's Link Magazine Fall 2023 / Vol 46 No 4

Distributor's Link Magazine Fall 2023 / Vol 46 No 4

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE DISTRIBUTOR’S LINK 173<br />

BRUNO MARBACHER THREAD-CUTTING SCREWS AND SELF-DRILLING SCREWS FOR SPECIAL APPLICATIONS from page 172<br />

The cold-headed drill points are sharp. This point<br />

prevents a spiral wandering off, when it is placed<br />

slightly off-angle. The drilling process can be started<br />

easily.<br />

However, if the point has a small web (chisel edge -<br />

similar to drills), the rotating point will wander off when<br />

it is placed on the work piece. The “web” is practically<br />

only found in very long, milled drill points, which are too<br />

long to be cold headed.<br />

Self-drilling screws are useful for drilling a wide range<br />

of materials like metal sheets, aluminum, stainless<br />

steel, wood and timber. They are widely used for<br />

electrical, insulation, roofing, construction, cladding<br />

and HVAC applications.<br />

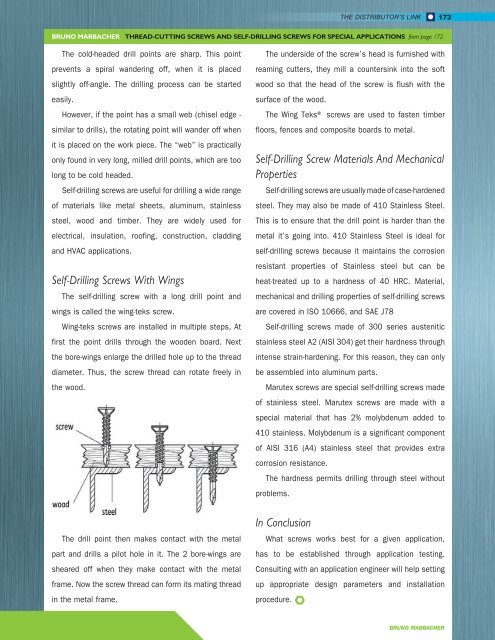

Self-Drilling Screws With Wings<br />

The self-drilling screw with a long drill point and<br />

wings is called the wing-teks screw.<br />

Wing-teks screws are installed in multiple steps, At<br />

first the point drills through the wooden board. Next<br />

the bore-wings enlarge the drilled hole up to the thread<br />

diameter. Thus, the screw thread can rotate freely in<br />

the wood.<br />

The underside of the screw’s head is furnished with<br />

reaming cutters, they mill a countersink into the soft<br />

wood so that the head of the screw is flush with the<br />

surface of the wood.<br />

The Wing Teks® screws are used to fasten timber<br />

floors, fences and composite boards to metal.<br />

Self-Drilling Screw Materials And Mechanical<br />

Properties<br />

Self-drilling screws are usually made of case-hardened<br />

steel. They may also be made of 410 Stainless Steel.<br />

This is to ensure that the drill point is harder than the<br />

metal it’s going into. 410 Stainless Steel is ideal for<br />

self-drilling screws because it maintains the corrosion<br />

resistant properties of Stainless steel but can be<br />

heat-treated up to a hardness of 40 HRC. Material,<br />

mechanical and drilling properties of self-drilling screws<br />

are covered in ISO 10666, and SAE J78<br />

Self-drilling screws made of 300 series austenitic<br />

stainless steel A2 (AISI 304) get their hardness through<br />

intense strain-hardening. For this reason, they can only<br />

be assembled into aluminum parts.<br />

Marutex screws are special self-drilling screws made<br />

of stainless steel. Marutex screws are made with a<br />

special material that has 2% molybdenum added to<br />

410 stainless. Molybdenum is a significant component<br />

of AISI 316 (A4) stainless steel that provides extra<br />

corrosion resistance.<br />

The hardness permits drilling through steel without<br />

problems.<br />

The drill point then makes contact with the metal<br />

part and drills a pilot hole in it. The 2 bore-wings are<br />

sheared off when they make contact with the metal<br />

frame. Now the screw thread can form its mating thread<br />

in the metal frame.<br />

In Conclusion<br />

What screws works best for a given application,<br />

has to be established through application testing.<br />

Consulting with an application engineer will help setting<br />

up appropriate design parameters and installation<br />

procedure.<br />

BRUNO MARBACHER