FALL 2023

Distributor's Link Magazine Fall 2023 / Vol 46 No 4

Distributor's Link Magazine Fall 2023 / Vol 46 No 4

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

188<br />

THE DISTRIBUTOR’S LINK<br />

LAURENCE CLAUS DIFFICULT FASTENING APPLICATIONS - PART 3: MIXED MATERIAL JOINTS from page 185<br />

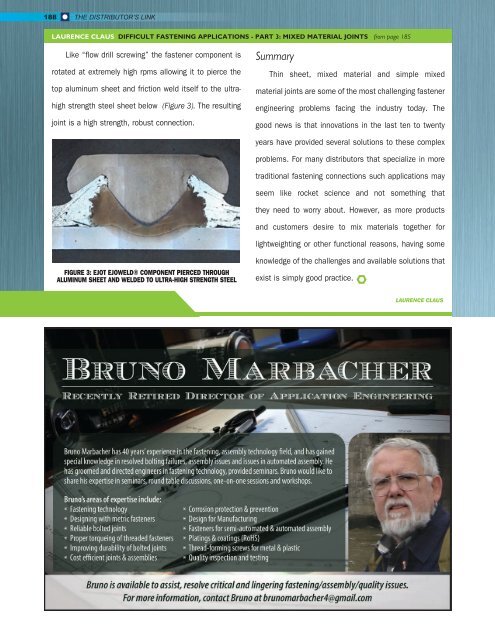

Like “flow drill screwing” the fastener component is<br />

rotated at extremely high rpms allowing it to pierce the<br />

top aluminum sheet and friction weld itself to the ultrahigh<br />

strength steel sheet below (Figure 3). The resulting<br />

joint is a high strength, robust connection.<br />

Summary<br />

Thin sheet, mixed material and simple mixed<br />

material joints are some of the most challenging fastener<br />

engineering problems facing the industry today. The<br />

good news is that innovations in the last ten to twenty<br />

years have provided several solutions to these complex<br />

problems. For many distributors that specialize in more<br />

traditional fastening connections such applications may<br />

seem like rocket science and not something that<br />

they need to worry about. However, as more products<br />

and customers desire to mix materials together for<br />

lightweighting or other functional reasons, having some<br />

FIGURE 3: EJOT EJOWELD® COMPONENT PIERCED THROUGH<br />

ALUMINUM SHEET AND WELDED TO ULTRA-HIGH STRENGTH STEEL<br />

knowledge of the challenges and available solutions that<br />

exist is simply good practice.<br />

LAURENCE CLAUS