NOVEMBER/DECEMBER 1983, No. 43, $3.50 Making ... - Wood Tools

NOVEMBER/DECEMBER 1983, No. 43, $3.50 Making ... - Wood Tools

NOVEMBER/DECEMBER 1983, No. 43, $3.50 Making ... - Wood Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

(continued)<br />

Methods of Work<br />

Y.<br />

out of a straight, flat lx4. <strong>No</strong>w rip another board half the<br />

diameter of your router base (measure from the center of the<br />

bit to the edge of the base) and secure it to the fence with flat<br />

hinges. As shown in the drawing, offset the hinges so that<br />

they won't protrude when the extension board is swung up<br />

out of the way. -James F. Dupler, Jamestown, N.<br />

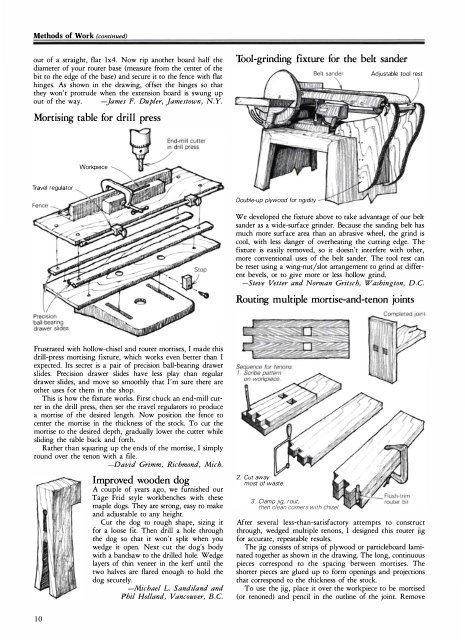

Mortising table for drill press<br />

Travel regulator<br />

Workpiece<br />

Frustrated with hollow-chisel and router mortises, I made this<br />

drill-press mortising fixture, which works even better than I<br />

expected. Its secret is a pair of precision ball-bearing drawer<br />

slides. Precision drawer slides have less play than regular<br />

drawer slides, and move so smoothly that I'm sure there are<br />

other uses for them in the shop.<br />

This is how the fixture works. First chuck an end-mill cutter<br />

in the drill press, then set the travel regulators to produce<br />

a mortise of the desired length. <strong>No</strong>w position the fence to<br />

center the mortise in the thickness of the stock. To cut the<br />

mortise to the desired depth, gradually lower the cutter while<br />

sliding the table back and forth.<br />

Rather than squaring up the ends of the mortise, I simply<br />

round over the tenon with a file.<br />

-David Grimm, Richmond, Mich.<br />

10<br />

Improved wooden dog<br />

A couple of years ago, we furnished our<br />

Tage Frid style workbenches with these<br />

maple dogs. They are strong, easy to make<br />

and adjustable to any height.<br />

Cut the dog to rough shape, sizing it<br />

for a loose fit. Then drill a hole through<br />

the dog so that it won't split when you<br />

wedge it open. Next cut the dog's body<br />

with a bandsaw to the drilled hole. Wedge<br />

layers of thin veneer in the kerf until the<br />

cwo halves are flared enough to hold the<br />

dog securely.<br />

-Michael L. Sandi land and<br />

Phil Holland, Vancouver, B.C.<br />

Tool-grinding fixture for the belt sander<br />

Double-up plywood for rigidity<br />

Adjustable tool rest<br />

We developed the fixture above to take advantage of our belt<br />

sander as a wide-surface grinder. Because the sanding belt has<br />

much more surface area than an abrasive wheel, the grind is<br />

cool, with less danger of overheating the cutting edge. The<br />

fixture is easily removed, so it doesn't interfere with other,<br />

more conventional uses of the belt sander. The tool rest can<br />

be reset using a wing-nut/slot arrangement to grind at different<br />

bevels, or to give more or less hollow grind.<br />

-Steve Vetter and <strong>No</strong>rman Gritsch, Washington, D.C.<br />

Routing multiple mortise-and-tenon joints<br />

2. Cut<br />

3. Clamp<br />

away<br />

most of waste.<br />

jig, rout.<br />

then clean corners with chisel.<br />

After several less-than-satisfactory attempts to construct<br />

through, wedged multiple tenons, I designed this router jig<br />

for accurate, repeatable results.<br />

The jig consists of strips of plywood or particleboard laminated<br />

together as shown in the drawing. The long, continuous<br />

pieces correspond to the spacing between mortises. The<br />

shorter pieces are glued up to form openings and projections<br />

that correspond to the thickness of the stock.<br />

To use the jig, place it over the workpiece to be mortised<br />

(or tenoned) and pencil in the outline of the joint. Remove