NOVEMBER/DECEMBER 1983, No. 43, $3.50 Making ... - Wood Tools

NOVEMBER/DECEMBER 1983, No. 43, $3.50 Making ... - Wood Tools

NOVEMBER/DECEMBER 1983, No. 43, $3.50 Making ... - Wood Tools

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Splitting Out a Firewood Tote<br />

This projea gets you started with green wood<br />

by Wizyne Ladd<br />

The ftrst time I met Vermont chairmaker Dave Sawyer, he<br />

was sitting on a shaving horse making a pitchfork. The<br />

only sounds were the creaking of the horse and the hiss of his<br />

drawknife. Having played at woodworking myself, I looked<br />

around the shop for the familiar router, bench saw and jointer,<br />

but saw only bits, braces, hand planes and, against one<br />

wall, a ftne bench. Sawyer asked if I knew of any ash trees for<br />

sale. As it turned out, a huge, straight ash had blown over on<br />

my land. The following week, wedges in hand, Sawyer came<br />

over to split the ttunk. We carried the splits to my car, then<br />

to his shop. The next day, I was amazed to fm d that he had a<br />

pitchfork made from my tree.<br />

I was so impressed with Sawyer's skill and practiced eye for<br />

simple, sturdy woodworking that I spent the following year as<br />

his part-time apprentice. One of the ftrst projects I learned<br />

was the log carrier shown here. Though the graceful bow<br />

gives the tote a fragile look, I've discovered that it can carry<br />

more wood than I care to heft at one time. And you can wrap<br />

twine around the foot rails and hang it from a rafter to make<br />

a wonderfully<br />

green<br />

sturdy indoor child's swing.<br />

Splitting wood-<strong>Making</strong> the log carrier from riven<br />

green wood affords some important advantages over sawn,<br />

kiln-dried wood. First, you can go straight to your woodlot,<br />

fell a tree, and then split, shave and assemble it into a ftnished<br />

produa, all in a matter of houts. Split along the grain<br />

instead of being sawn across it, riven wood is stronger than<br />

sawn wood, and satisfyingly easy to cut, bend and shape<br />

while green. You don't have to glue your projects together,<br />

either. Whittled tenons, dried over the woodstove, slip into<br />

mortises bored in wet wood, where they swell and lock the<br />

joint. For working green wood, you'll need two steel wedges,<br />

a mallet and a froe for splitting. A drawknife, spokeshave,<br />

brace and bit, and shaving horse complete the toolkit. For a<br />

shaving horse design, see the box on p. 41.<br />

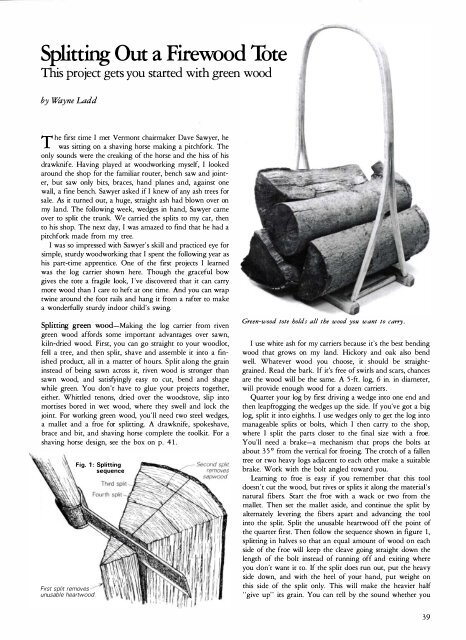

1: Fig. Splitting<br />

Firs t split removes<br />

unusable heartwood.<br />

sequence<br />

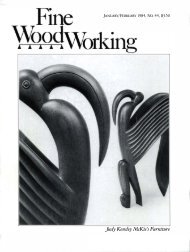

Green-wood tote holds all the wood you want to carry.<br />

I use white ash for my carriers because it's the best bending<br />

wood that grows on my land. Hickory and oak also bend<br />

well. Whatever wood you choose, it should be straightgrained.<br />

Read the bark. If it's free of swirls and scars, chances<br />

are the wood will be the same. A 5-ft. log, 6 in. in diameter,<br />

will provide enough wood for a dozen carriers.<br />

Quarter your log by ftrst driving a wedge into one end and<br />

then leapfrogging the wedges up the side. If you've got a big<br />

log, split it into eighths. I use wedges only to get the log into<br />

manageable splits or bolts, which I then carry to the shop,<br />

where I split the parts closer to the final size with a froe.<br />

You'll need a brake-a mechanism that props the bolts at<br />

about 350 from the vertical for froeing. The crotch of a fallen<br />

tree or two heavy logs adjacent to each other make a suitable<br />

brake. Work with the bolt angled toward you.<br />

Learning to froe is easy<br />

froe<br />

if you remember that this tool<br />

doesn't cut the wood, but rives or splits it along the material's<br />

natural fibers. Start the with a wack or two from the<br />

mallet. Then set the mallet aside, and continue the split by<br />

alternately levering the fibers apart and advancing the tool<br />

into the split. Split the unusable heartwood off the point of<br />

the quarter first. Then follow the sequence shown in ftgute 1,<br />

splitting in halves so that an equal amount of wood on each<br />

side of the froe will keep the cleave going straight down the<br />

length of the bolt instead of running off and exiting where<br />

you don't want it to. If the split does run out, put the heavy<br />

side down, and with the heel of your hand, put weight on<br />

this side of the split only. This will make the heavier half<br />

"give up" its grain. You can tell by the sound whether you<br />

39