NOVEMBER/DECEMBER 1983, No. 43, $3.50 Making ... - Wood Tools

NOVEMBER/DECEMBER 1983, No. 43, $3.50 Making ... - Wood Tools

NOVEMBER/DECEMBER 1983, No. 43, $3.50 Making ... - Wood Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

JOInter is nice, but what good is it if it's toO short to true a<br />

long board? Then there's the matter of switching from one<br />

function to the other. Aside from the nuisance, you can't use<br />

both jointer and planer simultaneously. This can force you to<br />

use more inefficient sequencing while truing your wood.<br />

I was disappointed with the Belsaw. Its low price isn't<br />

much of a value if half of the combination doesn't work. The<br />

people at Belsaw were helpful and happy to talk to me on<br />

their toll-free number, but goodwill can't offset a badly designed<br />

machine. Unless you are severely constrained by money,<br />

I can't recommend the Belsaw 684. On a tight budget,<br />

I'd consider Belsaw's model 804 planer-molder, about $550,<br />

and a separate jointer.<br />

The Emco-Rex 2000 is probably the better budget choice.<br />

It gets the job done, but it requires more care and skill to get<br />

good results than do the more expensive machines. Its sheetsteel<br />

construction gives me doubts about its durability.<br />

The Makita is a worthy machine which I liked better than<br />

the Belsaw or Emco. Yet it suffers in comparison with the<br />

Hitachi. The $150 lower price tag hardly offsets its draw-<br />

backs. Makita's lack of customer service (see box, below) persuades<br />

me to take my future business elsewhere.<br />

My difficulty is in choosing between the Hitachi and the<br />

Inca, machines that have obviously been designed according<br />

to different philosophies. Both are well designed and well<br />

made, though one is light and elegant, the other heavy and<br />

sturdy. I favor the Hitachi's side-by-side design, but I admire<br />

the Inca for its compactness and engineering fInesse. I think<br />

the Inca would be best for the craftsman who does careful,<br />

low-volume work and who doesn't often need to straighten<br />

long boards. I'm glad I bought the Hitachi, however. Apart<br />

from face-jointing wide boards, it can do all that the others<br />

can, with considerably more ease.<br />

u.s.<br />

It was the only machine on<br />

which the fence and tables were perfectly flat and straight. It's<br />

0<br />

built like a tank, and the people who sell it are knowledgeable<br />

and helpful. For me, that's a winning combination.<br />

James Rome is a part-time woodworker and full-time plasma<br />

physicist. He works for the fusion energy program<br />

in Oak Ridge, Tenn. Photos by the author.<br />

Don't answer the phone while adjusting jointer knives<br />

I was installing the knives in my Makita<br />

2030 jointer-planer when the phone<br />

rang. When I finished the call, I went<br />

back and turned on the machine, forgetting<br />

that I hadn't tightened the bolts.<br />

As the knives whirred up to speed, a<br />

horrible screeching noise ensued, followed<br />

by a shower of shrapnel. The<br />

jointer guard deflected most of the metal<br />

shards and I wasn't hurt.<br />

After I regained my composure, I realized<br />

what I had done wrong. It was a<br />

cheap lesson in how not to set jointer<br />

knives. Valuable as the experience was,<br />

I learned even more when I tried to fix<br />

the thing.<br />

Just taking it apart was a chore. The<br />

jointer tables are attached to the planer<br />

by hardened-steel drift pins. Driven into<br />

blind holes, these pins seem designed<br />

more for fast factoty assembly than for<br />

easy removal. Hours of tugging finally<br />

opened up a gap large enough to insert<br />

a hacksaw blade into. Several blades later,<br />

I cut through the pins and separated<br />

the tables.<br />

There followed another struggle to<br />

remove the jointer head from its pressfit<br />

into a bearing cup in the outfeed table.<br />

While doing this, I realized that if<br />

the drive belt connecting the motor to<br />

the shafts ever breaks, the jointer head<br />

will probably have to be removed to replace<br />

it. In principle, it might be possible<br />

to slide apart the coupled pulleys<br />

that connect the planer and jointer<br />

shafts, but in practice, forget it.<br />

I had to decide whether to fix the<br />

48<br />

tables or to buy new ones. This decision<br />

was surprisingly difficult. Although<br />

Makita stocks parts at various locations<br />

throughout the countty, each distribution<br />

center has different prices and tells<br />

a different Stoty. Makita in Atlanta was<br />

willing to sell me a new outfeed table<br />

for about $400. Makita in New Jersey<br />

claimed that they had a sale on an oldstyle<br />

outfeed table and the price was<br />

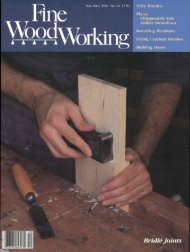

Rome 's knife-setting accident tore chunks<br />

from both infeed and outfeed tables. Here<br />

they are reinstalled, after being built up<br />

by nickel welding and flat grinding.<br />

$30. Makita in Atlanta said there was<br />

only one style of outfeed table. Makita<br />

in New Jersey said the sale was over.<br />

I decided to repair the machine. It<br />

cost me $ 5 0 to get the cast-iron tables<br />

welded back together with nickel. It<br />

cost another $ 50 to have the tops of the<br />

tables ground flat. The nickel was hard<br />

enough to ruin several carbide tools. I<br />

had to belt-sand down the bottoms of<br />

the welds facing the jointer head.<br />

Reassembling the 2030 was relatively<br />

straightforward. My struggles, however,<br />

were not over. Without the jointer<br />

blades, the machine ran smoothly up to<br />

speed. But when I installed the knives,<br />

it vibrated severely enough to walk<br />

across the floor of my shop. I weighed<br />

the blades and their cover plates, and<br />

found them to be perfectly balanced. I<br />

bought a new planer head (another<br />

$70) and readjusted the drive pulleys.<br />

The machine was still unbalanced.<br />

In disgust, I sold it, as a planer only,<br />

to a friend. He found the problem.<br />

When I ordered a new spring-steel<br />

blade holder, Makita had sent me two<br />

of them stuck together. This raised the<br />

blade and its heavy cover abour 1;6 in.,<br />

causing the out-of-balance condition.<br />

My misadventures with the Makita<br />

explain why I am now the owner of a<br />

Hitachi F- lOOOA. -J.A.R.<br />

EDITOR'S NOTE: To<br />

technical problems, Makita has recently<br />

sort out customers'<br />

added a national service manager to its<br />

staff. Write to 12950 E. A1ondra, Cerritos,<br />

Calif. 9070 1, or call (2 13)-926-8775.