NOVEMBER/DECEMBER 1983, No. 43, $3.50 Making ... - Wood Tools

NOVEMBER/DECEMBER 1983, No. 43, $3.50 Making ... - Wood Tools

NOVEMBER/DECEMBER 1983, No. 43, $3.50 Making ... - Wood Tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Cutting Dovetails With the Tablesaw<br />

A versatile way to join a stack of drawers<br />

by Mark Duginske<br />

For joining such basic casework as small boxes, chests and<br />

drawers, I've always felt that there was a missing link<br />

between the tedium of hand-cutting dozens of dovetails and<br />

the faster method of producing monotonous-looking joints<br />

with a router jig. With that in mind, I developed this tablesaw<br />

dovetail method which combines hand-tool flexibility<br />

with power-tool speed and accuracy.<br />

With this technique, you can vary both the width and the<br />

spacing of the pins and tails for praaically any aesthetic effect.<br />

The blocks that set the spacing are self-centering and will<br />

produce perfect-fitting, interchangeable joints, eliminating the<br />

need to mark boards so that individual joints will fit, as with<br />

hand-dovetailing. Besides a good combination sawblade and<br />

dado head for your tablesaw, you'll need a marking gauge, a<br />

bevel gauge and a couple of sharp bench chisels. Before proceeding,<br />

screw a wooden fence to the saw's miter gauge. A<br />

3-in. by 20-in. fence will safely support most work.<br />

Begin by squaring the ends of the boards to be joined.<br />

Take your time with this step-inaccurately prepared stock<br />

virtually guarantees sloppy results. I spaced the pins equally<br />

for the 4X-in. wide drawer parts I'm joining in the photos.<br />

You can mark the pin centers directly on the pin boards, or,<br />

as I did here, you can just cut the spacer blocks to create<br />

whatever spacing you want the pins to have. In any case, the<br />

width of the blocks should equal the distance between pin<br />

centers. You'll need one block for each full pin, plus one.<br />

The pin size is also controlled by the blocks. When they're<br />

lined up edge-to-edge, the total width of all the blocks<br />

should be less than the width of the stock by an amount<br />

equal to the width of the narrow part of each pin, that is, on<br />

the outside<br />

this<br />

face of the pin board. I chose<br />

be<br />

X-in. pins for the<br />

drawer sides shown in figure 1; if you want finer pins, decrease<br />

dimension. The blocks must of consistent width,<br />

so I crosscut them from the same ripping, then sandpaper off<br />

any fuzzy corners so that they'll line up with no gaps. To<br />

mark the depth of the pin and tail cuts, set your marking<br />

gauge to the stock thickness, and scribe a line on the faces of<br />

the pin board and on the face and edges of the tail board.<br />

Cut the tails first with the saw arbor (or table) tilted to<br />

80°, an angle that I've found produces the best combination<br />

of appearance and strength. A bevel gauge set at 80° can be<br />

used to set both the sawblade for the tails and, later, the<br />

miter gauge for the pins. As shown in figure 2, position and<br />

damp<br />

be<br />

a stop block to the miter-gauge fence so that when all<br />

the blocks are in place, a half-pin space of the correct size will<br />

CUt. At its narrowest width, the half-pin space should<br />

equal the narrow width of a pin. Raise the sawblade until it<br />

CUtS right to the gauge line, then, with all the blocks in place,<br />

begin cutting the tails, flipping the board edge-for-edge and<br />

end-for-end (photo, right). Continue this process, removing a<br />

spacer block each time, until all the tails are cut.<br />

A good-quality carbide-tipped blade will saw crisp pins<br />

50<br />

Fig. 1: Anatomy of a dovetail<br />

Half-pin<br />

Outside face<br />

Cut pins on fronts<br />

and backs of drawers,<br />

or tops and bottoms of carcases.<br />

I, j<br />

foE---<br />

Ta<br />

-4 ',4----':!-I<br />

"<br />

il 'boar�<br />

Socket<br />

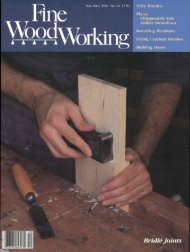

In Duginske 's tablesaw dovetail method, the tails are made first<br />

in a series of cuts with the table or arbor set at 800• After each<br />

series, a spacer block is removed and the cuts are repeated for the<br />

next tail. The last tail is made with one block in place.<br />

PhO[()s: Bill Scankus; drawings: David Dann