course contents - ug - National Institute of Technology Karnataka

course contents - ug - National Institute of Technology Karnataka

course contents - ug - National Institute of Technology Karnataka

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

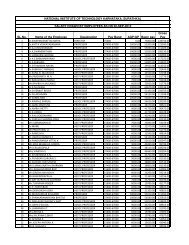

NATIONAL INSTITUTE OF TECHNOLOGY KARNATAKA, SURATHAKAL<br />

------------------------------------------------------------------------------------------------------------------<br />

Study <strong>of</strong> temperature distribution in a tubular furnace, oxidation and reduction roasting, pelletisation and<br />

sintering <strong>of</strong> iron ore fines, leaching studies, flotation <strong>of</strong> sulphide ores, oxidation <strong>of</strong> metals and alloys,<br />

cementation <strong>of</strong> copper, reducibility <strong>of</strong> ores, proximate analysis <strong>of</strong> coal, calorific value <strong>of</strong> solid fuels and<br />

gaseous fuels, flash and fire point determination using Cleveland's open cup and Pensky Marten's closed<br />

cup testers, determination <strong>of</strong> viscosity <strong>of</strong> liquids using Redwood viscometer and Brookfield viscometer,<br />

Orsat apparatus for gas analysis.<br />

MT350 PRODUCTION OF STEEL (3-0-0) 3 PREREQ: MT 302<br />

History <strong>of</strong> steel making, major steel making processes, principles <strong>of</strong> steel making, physical chemistry <strong>of</strong><br />

steel making, deoxidation, tapping and teeming, slags in steel making, raw materials for steel making,<br />

efficiency <strong>of</strong> steel making processes, layout <strong>of</strong> steel making shops, conventional pneumatic processes,<br />

open hearth steel making, oxygen steel making process: LD, Kaldo and Rotor processes, basic oxygen<br />

steel making, alloy steel making, continuous steel making, steel making in electric arc furnaces, steel<br />

making in induction furnaces, casting pit practice, continuous casting <strong>of</strong> steel, steel degassing processes,<br />

secondary steel making processes.<br />

R.H.Tupkary, Modern Steelmaking, Khanna Publishers, New Delhi.<br />

R.G.Ward, An Introduction to the Physical Chemistry <strong>of</strong> Iron and Steelmaking, ELBS, London.<br />

V.Kudrin, Steel Making, Mir Publication, Moscow.<br />

MT351 FATIGUE, FRACTURE AND CREEP (3-0-0) 3 PREREQ: MT 250<br />

Fatigue test: S-N curve, statistical nature, effect <strong>of</strong> mean stress, Goodman diagram, effect <strong>of</strong> surface<br />

finish, size, residual stress and temperature; effect <strong>of</strong> metallurgical variables, suppression <strong>of</strong> fatigue,<br />

fracture mechanics: type <strong>of</strong> fracture in metals, theoretical cohesion strength, Griffith theory, dislocation<br />

theory <strong>of</strong> fracture, plane strain fracture to<strong>ug</strong>hness and its evaluation, instrumented impact testing,<br />

comparison <strong>of</strong> fracture to<strong>ug</strong>hness <strong>of</strong> various materials, embrittlement <strong>of</strong> steels, creep and stress rupture,<br />

creep curve, stress rupture test, determination <strong>of</strong> fracture at higher temperature, presentation <strong>of</strong><br />

engineering creep data, prediction <strong>of</strong> long time practices, theories <strong>of</strong> creep, effect <strong>of</strong> metallurgical<br />

variables.<br />

Dieter G.E., Mechanical Metallurgy, McGraw Hill 1988 (SI Metric)<br />

Thomas H. Courtney, Mech. Behaviour <strong>of</strong> Metals, McGraw Hill 1990<br />

MT352 POWDER METALLURGY (3-0-0) 3 PREREQ: MT250<br />

Historical development <strong>of</strong> Powder Metallurgy, reasons for using powder metallurgy. Metal powder<br />

manufacturing techniques and powder characterization, Powder conditioning, Compaction and shaping,<br />

Sintering, Sintering atmospheres and equipments Secondary operations, testing, standards and quality<br />

controls, Apllications<br />

An introduction to powder Metallurgy, F. Thummler and R. Oberacker, The <strong>Institute</strong> <strong>of</strong> Materials, 1993<br />

ASm Handbook, powder Metallury Technologies and Applications, vol.7, ASm International, 1998.<br />

MT353 JOINING OF METALS (3-0-0) 3<br />

Classification <strong>of</strong> welding methods; electrodes, gas welding, MMAW, TIG, MIG, EBW, LBW, plasma<br />

welding, SAW, ESW, thermit welding, arc characteristics & metal transfer, equipment for welding,<br />

friction welding, ultrasonic welding, explosive welding, induction pressure welding, electrical resistance<br />

welding, production <strong>of</strong> tubes, diffusion bonding, welding <strong>of</strong> plain carbon steels, alloy steels, stainless<br />

steels and tool steels, cast iron and wro<strong>ug</strong>ht iron, copper, aluminium, magnesium, titanium & super<br />

alloys, welding <strong>of</strong> dissimilar metals, underwater welding, welding in vacuum, welding at low temperature<br />

(cryogenic welding), welding in space robotic welding, flame cutting, powder cutting, plasma cutting,<br />

laser cutting, electron beam cutting, fluxes, filler materials, solidification, micro & macrostructure,<br />

weldability and hardenablity, residual stresses, inspection and testing <strong>of</strong> welds, design <strong>of</strong> weldments,<br />

numerical problems in welding, use <strong>of</strong> computers in welding. Brazing & Soldering.<br />

N. K. Srinivasan, Welding <strong>Technology</strong>, Khanna Publishers, 1997<br />

---------------------------------------------------------------------<br />

NITK-Course Contents(UG)2010 Page 111 <strong>of</strong> 134