course contents - ug - National Institute of Technology Karnataka

course contents - ug - National Institute of Technology Karnataka

course contents - ug - National Institute of Technology Karnataka

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

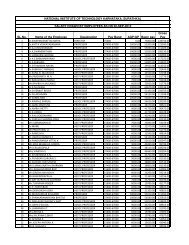

NATIONAL INSTITUTE OF TECHNOLOGY KARNATAKA, SURATHAKAL<br />

------------------------------------------------------------------------------------------------------------------<br />

Interpretation <strong>of</strong> results, Corrosion prevention; materials selection, alteration <strong>of</strong> environment, design,<br />

cathodic and anodic protection, coatings, high-temperature corrosion and mechanisms and kinetics, hightemperature<br />

materials<br />

Mars G. Fontana, Corrosion Engineering, McGraw-Hill Book Company, 1986<br />

David Talbot and James Talbot, Corrosion Science and <strong>Technology</strong>, CRC Press, New York, 1998<br />

Denny A. Jones, Principles and Prevention <strong>of</strong> Corrosion, Maxwell Matemillar 1992.<br />

MT405 PROCESS PLANT MATERIALS (3-0-0) 3<br />

Selection <strong>of</strong> process materials, fabrication, mechanical properties and strength <strong>of</strong> materials, effect <strong>of</strong><br />

temperature on mechanical properties, testing and inspection <strong>of</strong> materials, properties and uses <strong>of</strong> ferrous<br />

metals, cast iron, plain carbon steels, thermal and electrical insulating materials, non ferrous metals and<br />

alloys, general properties and fields <strong>of</strong> application <strong>of</strong> non ferrous metals, plastics as materials <strong>of</strong><br />

construction for chemical plant, corrosion resistance, uniform corrosion, galvanic corrosion, pitting,<br />

intergranular corrosion, effect <strong>of</strong> stress, erosion corrosion, high temperature oxidation, hydrogen<br />

embrittlement, selection for corrosion resistance, corrosion charts, design for corrosion resistance.<br />

William F. Smith, Principles <strong>of</strong> Material Science and Engineering, McGraw Hill Book Co.<br />

Vernon John, Engg Materials, 3 rd Edition, Macmillan, 1992.<br />

William D. Callister, Materials Science & Engg., 4 th Edition, John Wiley, 1997.<br />

MT406 EXTRACTION OF NON-FERROUS METALS (3-0-0) 3 PREREQ: MT 252<br />

Silver: sources, extraction by cyanidation, refining; gold: sources, concentration methods, gold recovery,<br />

refining; chromium: occurrence, production; cadmium: sources, extraction, recovery from secondary<br />

sources; mercury: sources, extraction from cinnabar; uranium: ores, processing <strong>of</strong> uranium ores, solvent<br />

extraction, reduction, production in India; thorium - sources, extraction and its purification; beryllium:<br />

types <strong>of</strong> ore, production, zirconium: sources, extraction and its refining, separation <strong>of</strong> Zr and Hf,<br />

fabrication <strong>of</strong> zirconium, production <strong>of</strong> zirconium in India; titanium: sources, beneficiation methods <strong>of</strong><br />

illmenite, production <strong>of</strong> titanium tetrachloride, the Kroll process; molybdenum: production <strong>of</strong> powder and<br />

ductile Mo; tungsten: ores, concentration methods, production <strong>of</strong> tungsten trioxide; production <strong>of</strong><br />

tungsten powder and ductile tungsten; tin: types, smelting <strong>of</strong> tin concentrates, refining <strong>of</strong> tin.<br />

H.S.Ray, A.Sridhar and K.P.Abraham, Extraction <strong>of</strong> Nonferrous Metals, 1985, EWP, New Delhi.<br />

Sevryukov N., Nonferrous Metallurgy, 1975, Mir, Moscow.<br />

W.H.Dennis - Metallurgy <strong>of</strong> the Non-Ferrous Metals, Ed.2, 1966, Pitman, London.<br />

MT407 SECONDARY REFINING OF STEELS (3-0-0) 3 PREREQ: MT 350<br />

Introduction, unit processes in secondary steelmaking viz stirring, slag control, refractories and<br />

atmosphere control: ladle furnace method; ladle injection metallurgy, vacuum treatment <strong>of</strong> liquid steel:<br />

priniciples, processes viz ladle, stream and circulation degassing methods, stainless steel making<br />

technology � VOD, AOD and CLII processes, remelting, refining processes � ESR and VAR processes.<br />

R.H.Tupkary, Modern Steelmaking, Khanna Publishers, New Delhi.<br />

R.G.Ward, An Introduction to the Physical Chemistry <strong>of</strong> Iron and Steelmaking, ELBS, London. V.Kudrin,<br />

Steel Making, Mir Publication, Moscow.<br />

MT408 NUCLEAR MATERIALS (3-0-0) 3<br />

Structure <strong>of</strong> a nuclear power plant, requirements <strong>of</strong> reactor materials, fuel materials, plutonium uranium<br />

and thorium and their alloys & compounds, core materials: beryllium, graphite, control and shielding<br />

materials, magnesium & its alloys, aluminium & its alloys, zirconium & its alloys, austenitic stainless<br />

steel; materials for reactor vessel and other components, pearlitic steels, ferritic, chromium stainless<br />

steels, copper alloys, titanium and its alloys, coolants used in reactors: radiation embrittlement, corrosion<br />

<strong>of</strong> reactor materials, mechanical properties <strong>of</strong> materials.<br />

---------------------------------------------------------------------<br />

NITK-Course Contents(UG)2010 Page 114 <strong>of</strong> 134