roweld cnc s4 - Rothenberger

roweld cnc s4 - Rothenberger

roweld cnc s4 - Rothenberger

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

24<br />

4.1 Initial commissioning / configuration<br />

4.1.1 Starting<br />

Use the two connection cables (12-pole/8-pole) to connect ROWELD DATALINE data logger to<br />

the CNC operator control unit. Turn coupling ring on connector fingertight. Place DATALINE<br />

data logger in the designated tray. Connect hydraulic couplings. Connect heating plate or<br />

heating plate sensor lead and distance sensor lead. Ensure that yokes snap tight. Connect<br />

trimmer with integrated SCUKO outlet only. Use SCHUKO outlet for trimmer only!<br />

If using a sensor lead, secure the lead with one of the enclosed cable ties to ensure<br />

that the lead cannot come into contact with the heating plate.<br />

Connect CNC operator control unit to mains. The device is now ready for use.<br />

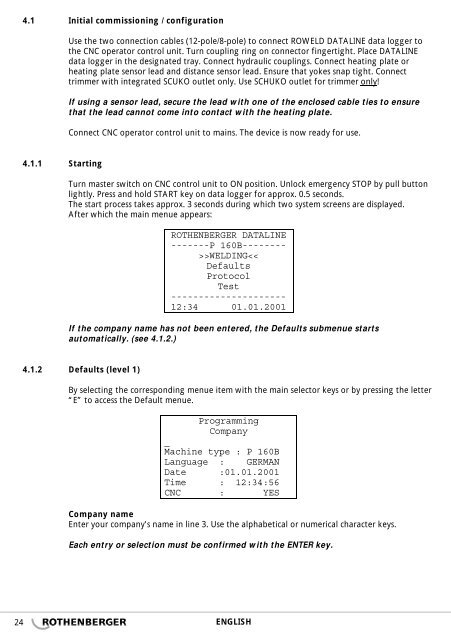

Turn master switch on CNC control unit to ON position. Unlock emergency STOP by pull button<br />

lightly. Press and hold START key on data logger for approx. 0.5 seconds.<br />

The start process takes approx. 3 seconds during which two system screens are displayed.<br />

After which the main menue appears:<br />

ROTHENBERGER DATALINE<br />

-------P 160B--------<br />

>>WELDING