Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

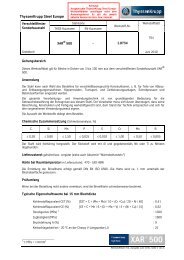

Production of hot-<strong>dip</strong> <strong>coated</strong> <strong>sheet</strong><br />

The process for the production of hot-<strong>dip</strong><br />

<strong>coated</strong> <strong>sheet</strong> follows directly on from the<br />

cold-rolling. This process combines in<br />

one line the cleaning, annealing, galvanizing<br />

and temper-rolling which in the<br />

production of electrogalvanized <strong>sheet</strong><br />

are each carried out on separate lines.<br />

The work-hardened strip is cleaned of<br />

emulsion residue and of iron abrasion<br />

from the cold-rolling process first roughly<br />

in a mechanical cleaning section, then<br />

finely in an electrolytic cleaning section.<br />

Following this, the strip, still work-hardened,<br />

passes into a continuous annealing<br />

furnace where it is recrystallized in a<br />

controlled atmosphere between 700 and<br />

850° C depending on the steel grade.<br />

Thus the <strong>sheet</strong> obtains the desired<br />

mechanical properties.<br />

Also in a controlled atmosphere the strip<br />

is cooled down in the subsequent<br />

15<br />

16<br />

17<br />

18 19 20 21 22 23<br />

annealing section of the furnace to a<br />

temperature of about 20° C above the<br />

bath temperature of the molten zinc of<br />

450° C in which it is <strong>dip</strong>ped while still<br />

in a controlled protective atmosphere.<br />

The zinc bath is temperature-controlled.<br />

Thanks to the intensive cleaning<br />

described above, an intermetallic interlayer<br />

is produced from an iron-aluminium<br />

compound as adhesion composite.<br />

In the case of hot-<strong>dip</strong> aluminium as with<br />

the GALVALUME ® coating a ternary ironaluminium-silicon<br />

compound produces<br />

the adhesion composite. The coating<br />

thickness, i.e. the coating ordered by<br />

the customer, is attained by air knives,<br />

on each the top and the bottom side of<br />

the strip, blowing pressure-controlled air<br />

or nitrogen on the strip and wiping off<br />

the excess zinc. A closed control system<br />

guarantees a uniform coating across the<br />

strip width and strip length. A different<br />

<strong>Hot</strong>-<strong>dip</strong> coating line<br />

1 Decoiler<br />

2 Shears<br />

3 Quality assurance (s. p. 17)<br />

4 Welding machine<br />

5 Strip cleaning<br />

6 Quality assurance (s. p. 17)<br />

7 Entry section<br />

8 Furnace<br />

9 Quality assurance (s. p. 17)<br />

10 Zinc pot (changing pot)<br />

11 Air knives<br />

12 Quality assurance (s. p. 17)<br />

13 Galvannealing furnace<br />

14 Quality assurance (s. p. 17)<br />

15 Cooling<br />

24<br />

coating for each side, the so-called differential<br />

coating, can also be produced.<br />

The temperature and the chemical composition<br />

of all baths are continuously<br />

checked. The whole process, subdivided<br />

into part processes, is computer-controlled.<br />

The now finished hot-<strong>dip</strong> <strong>coated</strong> <strong>sheet</strong><br />

can be temper-rolled continuously in the<br />

exit section of every plant and tension<br />

levelled. This way qualities with high<br />

surface requirements and flatness can<br />

be produced. <strong>Hot</strong>-<strong>dip</strong> aluminized <strong>sheet</strong><br />

is only supplied in tempered form.<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

Quality assurance (s. p. 17)<br />

Water cooling<br />

Quality assurance (s. p. 17)<br />

Temper-roll stand<br />

Tension-leveller<br />

Quality assurance (s. p. 17)<br />

Surface post-treatment<br />

Quality assurance (s. p. 17)<br />

Delivery strip accumulator<br />

Side-trimming shears<br />

Quality assurance/strip inspection (s. p. 17)<br />

Oiling<br />

Quality assurance (s. p. 17)<br />

Shears<br />

Coiler<br />

25<br />

26<br />

27 28 29<br />

30<br />

11