Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

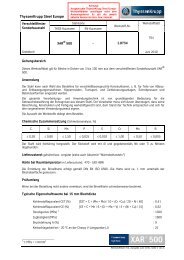

Mild steels for cold forming<br />

<strong>Hot</strong>-<strong>dip</strong> galvanized <strong>sheet</strong> (Z) and hot-<strong>dip</strong> galvanized <strong>sheet</strong><br />

Galvannealed (ZF) in accordance with DIN EN 10 142<br />

DX51D+Z; +ZF; max. 500<br />

DX52D+Z; +ZF; max. 300 2) max. 420<br />

DX53D+Z; +ZF; max. 260 max. 380<br />

DX54D+Z; +ZF; max. 220 max. 350<br />

DX56D+Z; +ZF; max. 180 max. 350<br />

GALFAN ® (ZA) in accordance with DIN EN 10 214 and<br />

GALVALUME ® (AZ) in accordance DIN EN 10 215<br />

DX51D+ZA; +AZ max. 500<br />

DX52D+ZA; +AZ max. 300 2) max. 420<br />

DX53D+ZA; +AZ max. 260 max. 380<br />

DX54D+ZA; +AZ max. 220 max. 350<br />

DX56D+ZA max. 180 max. 350<br />

<strong>Hot</strong>-<strong>dip</strong> aluminized <strong>sheet</strong> fal (AS) in accordance<br />

with DIN EN 10 154<br />

DX51D+AS; (basic quality A) max. 500<br />

DX52D+AS; (deep-drawing quality Bg) max. 300 max. 420<br />

DX53D+AS; (deep-drawing quality C) max. 260 max. 380<br />

DX54D+AS; (extra deep-drawing quality D) max. 220 max. 360<br />

DX55D+AS; (special mill quality T) max. 240 max. 370<br />

DX56D+AS; (extra deep drawing quality) max. 180 max. 330<br />

Structural steels<br />

Steel grades.<br />

Steel grades; name and Yield strength 1) Tensile strength Characterization<br />

standard designation R po,2 R m<br />

N/mm 2 N/mm 2<br />

<strong>Hot</strong>-<strong>dip</strong> galvanized <strong>sheet</strong> (Z) and hot-<strong>dip</strong> galvanized <strong>sheet</strong><br />

Galvannealed (ZF) in accordance with DIN EN 10 147<br />

S220GD+Z; +ZF min. 220 min. 300<br />

S250GD+Z; +ZF min. 250 min. 330<br />

S280GD+Z; +ZF min. 280 min. 360<br />

S320GD+Z; +ZF min. 320 min. 390<br />

S350GD+Z; +ZF min. 350 min. 420<br />

GALFAN ® (ZA) in accordance with DIN EN 10 214 and<br />

GALVALUME ® (AZ) in accordance with DIN EN 10 215<br />

S220GD+ZA; +AZ min. 220 min. 300<br />

S250GD+ZA; +AZ min. 250 min. 330<br />

S280GD+ZA; +AZ min. 280 min. 360<br />

S320GD+ZA; +AZ min. 320 min. 390<br />

S350GD+ZA; +AZ min. 350 min. 420<br />

<strong>Hot</strong>-<strong>dip</strong> aluminized <strong>sheet</strong> fal (AS) in accordance<br />

with DIN EN 10 154<br />

S250GD+AS; (L-250Al) min. 250 min. 330<br />

S280GD+AS; (M-280Al) min. 280 min. 360<br />

S320GD+AS; (N-320Al) min. 320 min. 390<br />

S350GD+AS; (O-350Al) min. 350 min. 420<br />

Beginning with the lock-forming (basic quality) quality<br />

for simple forming, through drawing and deep-drawing<br />

quality to the extra and special deep-drawing qualities.<br />

Each grade is defined by graduated maximum values<br />

of yield strength and by minimum values of elongation.<br />

The properties are determined by the melt analyses<br />

which vary within narrow ranges. The steel for the extra<br />

deep-drawing and special deep-drawing qualities is<br />

decarburized by vacuum treatment and stabilized with<br />

microalloy elements (Ti, Nb, V). These grades are<br />

resistant to ageing.<br />

After the basic quality for simple forming (bending,<br />

lock-forming), the Bg grade is suitable for drawing and<br />

stamping, but mainly for the production of welded<br />

pipes. The C and D grades can be used for difficult<br />

deep-drawing components, whereby the formability<br />

increases from C to D.<br />

The special mill quality has very good deep-drawing<br />

properties and is resistant to temperatures up to<br />

800° C. Because it also has an increased high-temperature<br />

yield point, it is suitable for automobile exhaust<br />

systems, combustion housings and for components in<br />

heat exchangers over which fuel gas flows.<br />

Graduated minimum values for yield strength, tensile<br />

strength and elongation. Main field of use is the building<br />

industry.<br />

1) The values apply to the 0.2 % proof strength (Rp0.2 ), if the yield strength is not pronounced. If the yield strength is pronounced, they apply in the case<br />

of general-purpose structural steels to the upper yield strength R . eL<br />

2) This value applies only to temper-rolled products (surface types B and C).<br />

45