Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

Before being wound into coils ready for<br />

shipping, the surface can be chemically<br />

passivated or oiled to protect it against<br />

temporary corrosion and friction oxidation.<br />

A combination of both surface<br />

treatments is also possible. The surface<br />

can be phosphate-treated as a drawing<br />

aid and as a pretreatment for subsequent<br />

painting, e.g. for a car body.<br />

Here, too, further oiling is possible. In<br />

addition, in two plants the surface can<br />

be sealed. In this process a plastic film<br />

of roughly 1 µm thickness is applied to<br />

a polyacrylic base via rollers (transparent<br />

coating). On the one hand this film<br />

is ideal temporary anti-corrosion protection,<br />

on the other hand it is an ideal<br />

lubricant for use in forming. For these<br />

reasons it is recommended that for<br />

GALVALUME ® the sealed surface treatment<br />

(designation “S”) be ordered.<br />

(See also section on protection against<br />

corrosion, p. 21).<br />

For reasons of corrosion protection, we<br />

would advise against ordering an<br />

untreated surface.<br />

The Galvannealed variant is produced<br />

by heat-treating the strip in a furnace<br />

downstream of the air knives.<br />

In the process, iron is diffused out of the<br />

basic material into the zinc layer, transforming<br />

it into a zinc-iron layer.<br />

The annealing process is controlled in<br />

such a way that a uniform Fe-level of<br />

8 – 11 % is achieved. The surface<br />

appears uniformly light grey.<br />

The GALFAN ® and GALVALUME ® products<br />

are produced in baths which have<br />

a modified composition when compared<br />

to the usual hot-<strong>dip</strong> galvanized <strong>sheet</strong><br />

and the Galvannealed variant. The<br />

GALFAN ® coating contains 95 % zinc<br />

and 5 % aluminium and in addition<br />

small amounts of cerium and lanthani-<br />

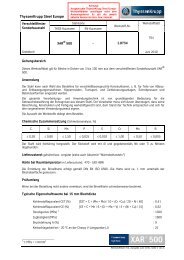

Ferndorf Bochum Dortmund Finnentrop<br />

FBA 6 FBA 7 FBA 8 FBA 3 Schmalbandverzinkung/<br />

<strong>Hot</strong>-<strong>dip</strong> narrow strip galvanizing<br />

Feuerverzinktes <strong>Feinblech</strong> (Z) Feuerverzinktes <strong>Feinblech</strong> (Z) Feuerverzinktes <strong>Feinblech</strong> (Z) Feuerverzinktes <strong>Feinblech</strong> (Z) Feuerverzinktes Schmalband<br />

Feuerverzinktes <strong>Feinblech</strong> Galvannealed<br />

(ZF)<br />

<strong>Hot</strong>-<strong>dip</strong> galvanized <strong>sheet</strong> (Z) <strong>Hot</strong>-<strong>dip</strong> galvanized <strong>sheet</strong> (Z) <strong>Hot</strong>-<strong>dip</strong> galvanized <strong>sheet</strong> (Z) <strong>Hot</strong>-<strong>dip</strong> galvanized <strong>sheet</strong> (Z) <strong>Hot</strong>-<strong>dip</strong> galvanized narrow strip<br />

Galvannealed <strong>sheet</strong> (ZF)<br />

700 –1525 mm 850 –1650 mm 750 –1650 mm 600 –1550 mm 14 – 200 mm<br />

0,35 – 4,0 mm 0,5 – 2,0 mm 0,30 –1,5 mm 0,4 – 3,25 mm 1,0 – 6,0 mm<br />

Chemisch passivieren (C) Chemisch passivieren (C) Phosphatieren (P) Chemisch passivieren (C)<br />

Ölen (O) Ölen (O) Chemisch passivieren (C) Versiegeln (S)<br />

Ölen (O) Ölen (O)<br />

Chemically passivated (C) Chemically passivated (C) Phosphate treated (P) Chemically passivated (C)<br />

Oiled (O) Oiled (O) Chemically passivated (C) Sealed (S)<br />

Oiled (O) Oiled (O)<br />

um. GALVALUME ® contains 55 % aluminium,<br />

a good 43 % zinc and just 2 %<br />

silicon. The coating of the hot-<strong>dip</strong> aluminized<br />

<strong>sheet</strong> consists of 10 % silicon,<br />

3 % iron with the remainder aluminium.<br />

The table below gives an overview of<br />

Thyssen Krupp Stahl AG’s hot-<strong>dip</strong> coating<br />

lines, including the narrow strip galvanizing<br />

line at the Finnentrop plant,<br />

and their various products. The hot-<strong>dip</strong><br />

coating line at the Dortmund plant designated<br />

FBA 8 is currently under construction<br />

and will come into operation in<br />

October 2001.<br />

<strong>Hot</strong>-<strong>dip</strong> coating lines at Thyssen Krupp Stahl AG<br />

Sack MDS Sundwig Stein-Heurtey/M&N Fröhling/Keramchemie<br />

AEG AEG Ansaldo AEG<br />

Stein-Heurtey/Italimpianti Drewer Selas Stein-Heurtey Electric Furnace<br />

1976/81/90 1992/97 2001 1) 1964/82/91/98 1973<br />

150 m/min 180 m/min 180 m/min 120 m/min 12 m/min<br />

15 t 40 t 35 t 25 t 1,8 t<br />

13<br />

1) Completion 10/2001