Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

Formability<br />

A hot-<strong>dip</strong> <strong>coated</strong> <strong>sheet</strong> must not only be<br />

resistant to corrosion, but also have<br />

good forming properties. The investigation<br />

of material characteristics for good<br />

formability is thus a key research activity.<br />

To assess formability the mechanical<br />

properties are determined in tensile<br />

tests and the forming limit curve is<br />

established. On specially designed testing<br />

machines, flat samples and structurally<br />

similar samples can be tested<br />

under cyclical loads and load graphs<br />

can be established. The random fatigue<br />

is studied in near-operational load<br />

cycles.<br />

Using components, the energy absorption<br />

values of various steels is determined<br />

on a crash test bed (drop weight<br />

tear test bed). Measuring devices are<br />

available to ascertain roughness, with<br />

the possibility of realizing a threedimensional<br />

diagram and measuring the<br />

tribological behaviour of various <strong>sheet</strong><br />

surfaces.<br />

In order to do justice to the complexity<br />

of the drawing behaviour in the forming<br />

process and to establish the material<br />

influence on part behaviour with regard<br />

to splitting, wrinkling formation and<br />

elastic recovery, parts can be pressed in<br />

the original size on a threefold-working<br />

hydraulic punching and drawing press.<br />

Using a hydromechanical forming process<br />

(working medium water), an<br />

attempt is made to utilize in a better<br />

way the possibilities offered by high tensile<br />

steels for light gauge design.<br />

For the external hydroforming process<br />

(AHU ® ) a 2,000 t press is available.<br />

Structural components can be produced<br />

from welded hollows using the internal<br />

hydroforming process (IHU). Knowledge<br />

about the dent characteristic of a component<br />

is of great interest for the automobile<br />

industry. This dent resistance is<br />

determined on a company-developed,<br />

computer-supported dent test bed,<br />

which can be used to measure component<br />

coordinates. Is it at all possible to<br />

produce a certain component from a<br />

certain material? Using the finite element<br />

method (FEM), this question is<br />

examined on a computer so that without<br />

carrying out forming tests the first<br />

answers can be given as to critical tool<br />

areas or unsuitable materials.<br />

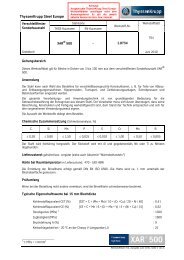

Beulprüfstand zur Ermittlung der Beulfestigkeit<br />

an großflächigen Außenhautteilen.<br />

Dent test bed to determine dent resistance<br />

of exposed parts.<br />

35