Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

Formability<br />

All forming processes for the cold-rolled<br />

steel can be used for hot-<strong>dip</strong> <strong>coated</strong><br />

<strong>sheet</strong>s, if tool surface and geometry are<br />

suited to these materials. The last finishing<br />

operation of the tool surface must<br />

take place in the direction of the <strong>sheet</strong><br />

metal flow. This also applies to the<br />

drawing beads and draw radii. The<br />

drawing opening and draw radius may<br />

have to be somewhat enlarged. The tool<br />

surface must be absolutely scratch-free<br />

to avoid abrasion from the coating<br />

which commonly occurs at high forming<br />

unit cycle times. The abrasion can be<br />

minimized by using a suitable drawing<br />

aid or a phospate-treated strip surface.<br />

If possible a thin metallic coating should<br />

always be chosen, as far as the corrosion<br />

protection requirements allow.<br />

The resulting friction forces are significantly<br />

lower than with cold-rolled <strong>sheet</strong><br />

of comparable roughness because of<br />

the metallic coating. Thus the forming<br />

efficiency is increased, which often<br />

results in a higher limiting drawing ratio<br />

or in a greater depth of draw. Due to the<br />

lower friction, higher blank holder forces<br />

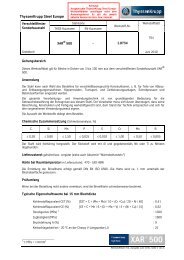

Abrieb der Beschichtungen bei verschiedenen<br />

schmelztauchveredelten <strong>Feinblech</strong>en<br />

Coating abrasion of different hot-<strong>dip</strong> <strong>coated</strong> <strong>sheet</strong>s<br />

Abriebmenge/Mass of abrasion [g/m 2 ]<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

are required when deep drawing than<br />

with cold-rolled <strong>sheet</strong>, with the result<br />

that, although the applicable working<br />

range shifts in terms of level, it is not<br />

restrictive. Just as for cold-rolled <strong>sheet</strong>,<br />

a certain roughness of the hot-<strong>dip</strong> galvanized<br />

<strong>sheet</strong> surface permits optimal<br />

production conditions and safe transportation<br />

of parts through suction cups.<br />

This roughness is adjusted during<br />

temper-rolling.<br />

<strong>Hot</strong>-<strong>dip</strong> galvanized <strong>sheet</strong> Galvannealed<br />

is just as suitable for all deep drawing<br />

processes as normal hot-<strong>dip</strong> galvanized<br />

<strong>sheet</strong>. Due to the iron content in the zinc<br />

layer, the frictional behaviour is more<br />

similar to that of cold-rolled <strong>sheet</strong>.<br />

Because of the higher frictional values,<br />

smaller blank dimensions can be chosen<br />

with stretch forming parts. The fact that<br />

the zinc-iron layer is somewhat less<br />

ductile than the pure zinc layer has to<br />

be borne in mind when lubricating,<br />

maintaining tools and designing the<br />

radii.<br />

All the above-mentioned criteria relating<br />

to hot-<strong>dip</strong> galvanized <strong>sheet</strong> apply<br />

correspondingly to GALFAN ® and<br />

Werkzeugstahl gehärtet;<br />

Ziehgeschwindigkeit = 6 m/min;<br />

Schmiermittel: RP4107S;<br />

2 g/m 2 Oberfläche<br />

Hardened tool steel;<br />

Drawing speed = 6 m/min.;<br />

Lubricant: RP4107S;<br />

2 g/m 2 surface<br />

Kaltfeinblech/Cold-rolled <strong>sheet</strong><br />

Feueraluminiert/<strong>Hot</strong>-<strong>dip</strong> aluminized<br />

GALVALUME ®<br />

GALFAN ®<br />

Feuerverzinkt/<strong>Hot</strong>-<strong>dip</strong> galvanized<br />

Galvannealed<br />

Galvannealed und vorphosphatiert/<br />

Galvannealed and pre-phosphated<br />

GALVALUME ® . GALFAN ® has especially<br />

good forming properties because the<br />

bending angle shows fewer hairline<br />

cracks than hot-<strong>dip</strong> galvanized <strong>sheet</strong><br />

even with narrow radii. The reason lies<br />

in the structure of the very ductile coating.<br />

GALVALUME ® is more liable to<br />

cracking due to the brittle ternary ironaluminium-silicon<br />

layer. Usually these<br />

fine hairline cracks, e.g. when roll-forming<br />

with narrow radii, do not reduce the<br />

corrosion protection, as here too the<br />

zinc content in the coating protects the<br />

steel underneath cathodically. Nor are<br />

appearance and paintability diminished.<br />

The formability of the various hot-<strong>dip</strong><br />

<strong>coated</strong> products is always the same for<br />

comparable steel grades. Although the<br />

values of the tensile test tend to be<br />

worse for products with a harder coating,<br />

i.e. galvannealed and GALVA-<br />

LUME ® , the coating itself does not influence<br />

formability. Because of a certain<br />

sensitivity of the GALVALUME ® surface<br />

to damage in general and especially with<br />

regard to fingerprints, the surface<br />

should be sealed during production (see<br />

page 13). This sealing protects against<br />

surface damage during forming and<br />

against unsightly signs of handling,<br />

works as a lubricant so that it can be<br />

roll-formed without oil and reduces tool<br />

abrasion. The sealed surface can be<br />

painted without problem.<br />

23