Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

Corrosion protection<br />

A zinc coating applied to steel in an<br />

immersion process has for a long time<br />

been ideal in corrosion protection.<br />

The zinc actually protects the steel<br />

underneath in two ways:<br />

• First the zinc layer forms an adhering<br />

protective jacket, which protects the<br />

steel when subjected to weathering<br />

(barrier effect).<br />

• On the cut edges and those places<br />

where this jacket sustains damage<br />

through to the steel base, the base<br />

zinc first dissolves in a conducting<br />

medium (dirt, drops of water), i.e.<br />

“is consumed”, before the steel is<br />

attacked. This is termed the “cathodic<br />

protective effect” of zinc.<br />

In the cases of GALFAN ® and<br />

GALVALUME ® the corrosion resistance<br />

is improved by the aluminium in the<br />

coating, so that it is possible to work<br />

with thinner coatings. GALVALUME ®<br />

corresponds to the corrosion protection<br />

class III of DIN 55 928, part 8. Where<br />

by damage or cut edges, zinc is “consumed”<br />

over time as a result of the<br />

cathodic protection, the aluminium in<br />

between continues to protect the steel.<br />

A special finish is produced by adding<br />

an organic thin-film coating. This is<br />

applied at a thickness of 3 – 6 µm in the<br />

coil-coating process. It is pigmented to<br />

guarantee weldability. This thin-<strong>coated</strong><br />

<strong>sheet</strong> can be formed, welded and painted<br />

using the usual processes, though<br />

the process parameters may have to be<br />

adapted. The field of application is the<br />

autobody area in the automotive industry,<br />

where significantly improved<br />

corrosion protection can be achieved,<br />

especially in the flange area, when used<br />

in accordance with the design. Secondary<br />

corrosion protection measures<br />

such as wax soaking, seam sealing and<br />

the like may be unnecessary.<br />

The corrosion protection can be significantly<br />

enhanced by a paint coating.<br />

If the hot-<strong>dip</strong> <strong>coated</strong> <strong>sheet</strong>s are<br />

arranged according to the most important<br />

corrosion criteria and compared to<br />

cold-rolled steel, the results are:<br />

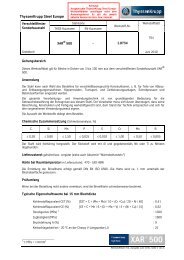

Kriterium Feuerverzinkt Galvannealed GALFAN ® GALVALUME ® Feueraluminiert Kaltfeinblech<br />

Criterion <strong>Hot</strong>-<strong>dip</strong> galvanized Galvannealed GALFAN ® GALVALUME ® <strong>Hot</strong>-<strong>dip</strong> aluminized Cold-rolled <strong>sheet</strong><br />

Korrosionsbeständigkeit,<br />

unlackiert<br />

gut – verbessert hervorragend hervorragend –<br />

Corrosion resistance<br />

unpainted<br />

good – improved excellent excellent –<br />

Lackierbarkeit (KTL) gut zufrieden stellend gut – – hervorragend<br />

Paintability (KTL) good satisfactory good – – excellent<br />

Korrosionsbeständigkeit,<br />

lackiert (KTL)<br />

gut hervorragend gut – – noch gut<br />

Corrosion resistance<br />

painted (KTL)<br />

good excellent good – – still good<br />

Phosphatierbarkeit gut hervorragend zufrieden stellend – – hervorragend<br />

Phosphateability good excellent satisfactory – – excellent<br />

Kraftstoffbeständigkeit zufrieden stellend – zufrieden stellend – hervorragend unzureichend<br />

Fuel stability satisfactory – satisfactory – excellent inadequate<br />

KTL = Kathodische Tauchlackierung/Cathodic painting<br />

21