Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Schmelztauchveredeltes Feinblech.Hot-dip coated sheet.

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

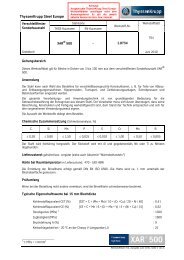

Steel grades; name and Yield strength 1) Tensile strength Characterization<br />

standard designation R po,2 R m<br />

N/mm 2 N/mm 2<br />

High-strength steels<br />

<strong>Hot</strong>-<strong>dip</strong> galvanized <strong>sheet</strong> (Z), hot-<strong>dip</strong> galvanized <strong>sheet</strong> galvannealed (ZF),<br />

GALFAN ® (ZA) from high-strength IF steel in accordance with<br />

DIN EN 10 292; TKS work designation HX …<br />

H180YD+Z; +ZF; +ZA 180 – 240 340 – 400<br />

H220YD+Z; +ZF; +ZA 220 – 280 340 – 410<br />

H260YD+Z; +ZF; +ZA 260 – 320 380 – 440<br />

<strong>Hot</strong>-<strong>dip</strong> galvanized <strong>sheet</strong> (Z), hot-<strong>dip</strong> galvanized <strong>sheet</strong> Galvannealed (ZF),<br />

GALFAN ® (ZA) from micro-alloyed steel in accordance with DIN EN 10 292;<br />

TKS work designation MHZ …<br />

H300LAD+Z; +ZF; +ZA 300 – 380 380 – 480<br />

H340LAD+Z; +ZF; +ZA 340 – 420 410 – 510<br />

H380LAD+Z; +ZF; +ZA 380 – 480 440 – 560<br />

<strong>Hot</strong>-<strong>dip</strong> galvanized <strong>sheet</strong> (Z), GALFAN ® (ZA), from phosphorus-alloyed steel<br />

accordance with DIN EN 10 292; TKS work designation PHZ …<br />

H220PD+Z; +ZA 220 – 280 340 – 400<br />

H260PD+Z; +ZA 260 – 320 380 – 440<br />

H300PD+Z; +ZA 300 – 360 400 – 480<br />

<strong>Hot</strong>-<strong>dip</strong> galvanized <strong>sheet</strong> (Z), and hot-<strong>dip</strong> galvanized <strong>sheet</strong> Galvannealed (ZF),<br />

from bake-hardening steel; TKS works designation BHZ …<br />

H180BD+Z; +ZF 180 – 240 300 – 360<br />

H220BD+Z; +ZF 220 – 280 340 – 400<br />

H260BD+Z; +ZF 260 – 320 360 – 440<br />

H300BD+Z; +ZF (test phase) 300 – 360 400 – 480<br />

<strong>Hot</strong>-<strong>dip</strong> galvanized <strong>sheet</strong> (Z) and hot-<strong>dip</strong> galvanized <strong>sheet</strong> Galvannealed (ZF)<br />

from dual phase steel; TKS works designation DP-K ® …<br />

DP-K27/50+Z; +ZF (test phase) min. 270 min. 500<br />

DP-K30/50+Z; +ZF (test phase) min. 300 min. 500<br />

DP-K31/60+Z; +ZF min. 310 min. 600<br />

DP-K34/60+Z; +ZF min. 340 min. 600<br />

DP-K38/60+Z; +ZF min. 380 min. 600<br />

<strong>Hot</strong>-<strong>dip</strong> galvanized <strong>sheet</strong> (Z) and hot-<strong>dip</strong> galvanized <strong>sheet</strong> Galvannealed (ZF)<br />

from residual austenite steel (trip steel); TKS works designation RA-K ® …<br />

RA-K38/60+Z; +ZF (test phase) min. 380 min. 600<br />

RA-K40/70+Z; +ZF min. 400 min. 700<br />

RA-K42/80+Z; +ZF (test phase) min. 420 min. 800<br />

Other grades also in accordance with foreign standards or customer specifications by arrangement.<br />

IF steel; very good deep-drawing and stretch-forming<br />

ability in lower strength range; high r-and n-values;<br />

suitable for difficult deep-drawing components.<br />

A high component strength level can be achieved by<br />

the ability to meet accurate specifications in alloying<br />

technology.<br />

Good deep drawability through comparatively high<br />

r-value; suitable for deep-drawing components in<br />

intermediate strength range.<br />

Increase in strength only after forming and subsequent<br />

heat treatment (e.g. paint-baking); suitable for flat<br />

stretch-drawing components, which require high dent<br />

resistance. Both types of the H220BD and H260BD<br />

grades have isotropic properties.<br />

High strength level due to martensite islands in ferritic<br />

basis microstructure; good isotropic forming properties<br />

in upper strength range with favourable elasticity; high<br />

BH potential, high capacity for hardening and energy<br />

absorption; suitable for stretch-forming components<br />

(outer and inner) of auto body, above all for crash-relevant<br />

components.<br />

Very high strength level due to residual austenite in<br />

ferritic-bainitic basic microstructure which converts to<br />

martensite during forming; at the same time good<br />

isotropic properties; high capacity for energy absorption;<br />

high BH potential; suitable for inner supporting<br />

components having at the same time stretch-forming<br />

and deep-drawing properties.<br />

1) The values apply to the 0.2 % proof strength (Rp0.2 ), if the yield strength is not pronounced. If the yield strength is pronounced, they apply to the upper<br />

yield strength R . eL<br />

47