Final Fairing & Finishing - WEST SYSTEM Epoxy

Final Fairing & Finishing - WEST SYSTEM Epoxy

Final Fairing & Finishing - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

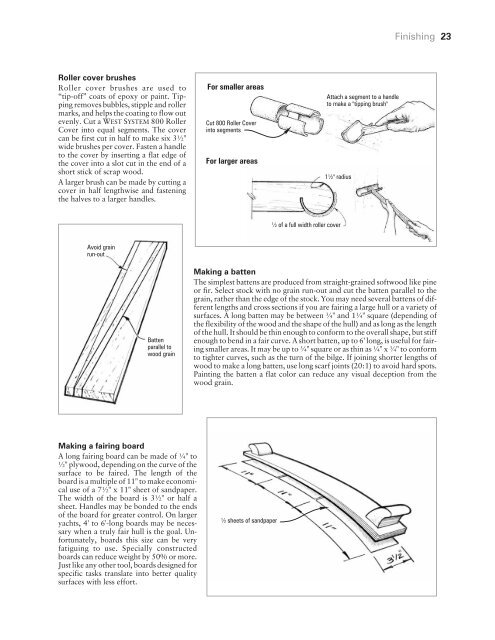

Roller cover brushes<br />

Roller cover brushes are used to<br />

“tip-off” coats of epoxy or paint. Tipping<br />

removes bubbles, stipple and roller<br />

marks, and helps the coating to flow out<br />

evenly. Cut a <strong>WEST</strong> <strong>SYSTEM</strong> 800 Roller<br />

Cover into equal segments. The cover<br />

can be first cut in half to make six 3½"<br />

wide brushes per cover. Fasten a handle<br />

to the cover by inserting a flat edge of<br />

the cover into a slot cut in the end of a<br />

short stick of scrap wood.<br />

A larger brush can be made by cutting a<br />

cover in half lengthwise and fastening<br />

the halves to a larger handles.<br />

Avoid grain<br />

run-out<br />

Batten<br />

parallel to<br />

wood grain<br />

Making a fairing board<br />

A long fairing board can be made of ¼" to<br />

½" plywood, depending on the curve of the<br />

surface to be faired. The length of the<br />

board is a multiple of 11" to make economical<br />

use of a 7½" x 11" sheet of sandpaper.<br />

The width of the board is 3½" or half a<br />

sheet. Handles may be bonded to the ends<br />

of the board for greater control. On larger<br />

yachts, 4' to 6'-long boards may be necessary<br />

when a truly fair hull is the goal. Unfortunately,<br />

boards this size can be very<br />

fatiguing to use. Specially constructed<br />

boards can reduce weight by 50% or more.<br />

Just like any other tool, boards designed for<br />

specific tasks translate into better quality<br />

surfaces with less effort.<br />

For smaller areas<br />

Cut 800 Roller Cover<br />

into segments<br />

For larger areas<br />

<strong>Finishing</strong> 23<br />

Making a batten<br />

The simplest battens are produced from straight-grained softwood like pine<br />

or fir. Select stock with no grain run-out and cut the batten parallel to the<br />

grain, rather than the edge of the stock. You may need several battens of different<br />

lengths and cross sections if you are fairing a large hull or a variety of<br />

surfaces. A long batten may be between ¾" and 1¼" square (depending of<br />

the flexibility of the wood and the shape of the hull) and as long as the length<br />

of the hull. It should be thin enough to conform to the overall shape, but stiff<br />

enough to bend in a fair curve. A short batten, up to 6' long, is useful for fairing<br />

smaller areas. It may be up to ¾" square or as thin as ¼" x ¾" to conform<br />

to tighter curves, such as the turn of the bilge. If joining shorter lengths of<br />

wood to make a long batten, use long scarf joints (20:1) to avoid hard spots.<br />

Painting the batten a flat color can reduce any visual deception from the<br />

wood grain.<br />

½ sheets of sandpaper<br />

½ of a full width roller cover<br />

Attach a segment to a handle<br />

to make a "tipping brush"<br />

1½" radius