Implementation of Metal Casting Best Practices - EERE - U.S. ...

Implementation of Metal Casting Best Practices - EERE - U.S. ...

Implementation of Metal Casting Best Practices - EERE - U.S. ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

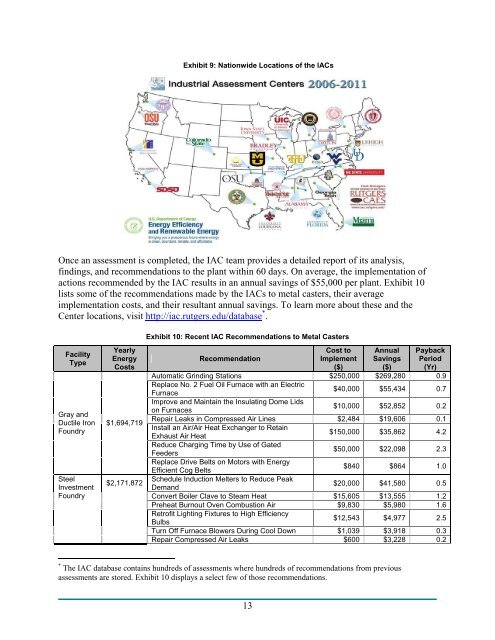

Exhibit 9: Nationwide Locations <strong>of</strong> the IACs<br />

Once an assessment is completed, the IAC team provides a detailed report <strong>of</strong> its analysis,<br />

findings, and recommendations to the plant within 60 days. On average, the implementation <strong>of</strong><br />

actions recommended by the IAC results in an annual savings <strong>of</strong> $55,000 per plant. Exhibit 10<br />

lists some <strong>of</strong> the recommendations made by the IACs to metal casters, their average<br />

implementation costs, and their resultant annual savings. To learn more about these and the<br />

Center locations, visit http://iac.rutgers.edu/database * .<br />

Facility<br />

Type<br />

Gray and<br />

Ductile Iron<br />

Foundry<br />

Steel<br />

Investment<br />

Foundry<br />

Yearly<br />

Energy<br />

Costs<br />

$1,694,719<br />

$2,171,872<br />

Exhibit 10: Recent IAC Recommendations to <strong>Metal</strong> Casters<br />

Recommendation<br />

Cost to<br />

Implement<br />

($)<br />

Annual<br />

Savings<br />

($)<br />

Payback<br />

Period<br />

(Yr)<br />

Automatic Grinding Stations $250,000 $269,280 0.9<br />

Replace No. 2 Fuel Oil Furnace with an Electric<br />

Furnace<br />

$40,000 $55,434 0.7<br />

Improve and Maintain the Insulating Dome Lids<br />

on Furnaces<br />

$10,000 $52,852 0.2<br />

Repair Leaks in Compressed Air Lines $2,484 $19,606 0.1<br />

Install an Air/Air Heat Exchanger to Retain<br />

Exhaust Air Heat<br />

$150,000 $35,862 4.2<br />

Reduce Charging Time by Use <strong>of</strong> Gated<br />

Feeders<br />

$50,000 $22,098 2.3<br />

Replace Drive Belts on Motors with Energy<br />

Efficient Cog Belts<br />

$840 $864 1.0<br />

Schedule Induction Melters to Reduce Peak<br />

Demand<br />

$20,000 $41,580 0.5<br />

Convert Boiler Clave to Steam Heat $15,605 $13,555 1.2<br />

Preheat Burnout Oven Combustion Air $9,830 $5,980 1.6<br />

Retr<strong>of</strong>it Lighting Fixtures to High Efficiency<br />

Bulbs<br />

$12,543 $4,977 2.5<br />

Turn Off Furnace Blowers During Cool Down $1,039 $3,918 0.3<br />

Repair Compressed Air Leaks $600 $3,228 0.2<br />

* The IAC database contains hundreds <strong>of</strong> assessments where hundreds <strong>of</strong> recommendations from previous<br />

assessments are stored. Exhibit 10 displays a select few <strong>of</strong> those recommendations.<br />

13