Is it necessary to install a downhole safety valve in a subsea ... - NTNU

Is it necessary to install a downhole safety valve in a subsea ... - NTNU

Is it necessary to install a downhole safety valve in a subsea ... - NTNU

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Is</strong> <strong>it</strong> <strong>necessary</strong> <strong>to</strong> <strong><strong>in</strong>stall</strong> a <strong>downhole</strong> <strong>safety</strong> <strong>valve</strong> <strong>in</strong> a <strong>subsea</strong> oil/gas well?<br />

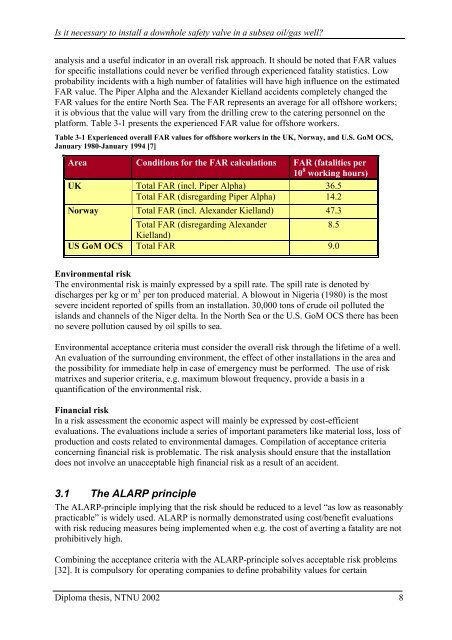

analysis and a useful <strong>in</strong>dica<strong>to</strong>r <strong>in</strong> an overall risk approach. It should be noted that FAR values<br />

for specific <strong><strong>in</strong>stall</strong>ations could never be verified through experienced fatal<strong>it</strong>y statistics. Low<br />

probabil<strong>it</strong>y <strong>in</strong>cidents w<strong>it</strong>h a high number of fatal<strong>it</strong>ies will have high <strong>in</strong>fluence on the estimated<br />

FAR value. The Piper Alpha and the Alexander Kielland accidents completely changed the<br />

FAR values for the entire North Sea. The FAR represents an average for all offshore workers;<br />

<strong>it</strong> is obvious that the value will vary from the drill<strong>in</strong>g crew <strong>to</strong> the cater<strong>in</strong>g personnel on the<br />

platform. Table 3-1 presents the experienced FAR value for offshore workers.<br />

Table 3-1 Experienced overall FAR values for offshore workers <strong>in</strong> the UK, Norway, and U.S. GoM OCS,<br />

January 1980-January 1994 [7]<br />

Area Cond<strong>it</strong>ions for the FAR calculations FAR (fatal<strong>it</strong>ies per<br />

10 8 work<strong>in</strong>g hours)<br />

UK<br />

Total FAR (<strong>in</strong>cl. Piper Alpha) 36.5<br />

Total FAR (disregard<strong>in</strong>g Piper Alpha) 14.2<br />

Norway<br />

Total FAR (<strong>in</strong>cl. Alexander Kielland) 47.3<br />

Total FAR (disregard<strong>in</strong>g Alexander<br />

Kielland)<br />

8.5<br />

US GoM OCS Total FAR 9.0<br />

Environmental risk<br />

The environmental risk is ma<strong>in</strong>ly expressed by a spill rate. The spill rate is denoted by<br />

discharges per kg or m 3 per <strong>to</strong>n produced material. A blowout <strong>in</strong> Nigeria (1980) is the most<br />

severe <strong>in</strong>cident reported of spills from an <strong><strong>in</strong>stall</strong>ation. 30,000 <strong>to</strong>ns of crude oil polluted the<br />

islands and channels of the Niger delta. In the North Sea or the U.S. GoM OCS there has been<br />

no severe pollution caused by oil spills <strong>to</strong> sea.<br />

Environmental acceptance cr<strong>it</strong>eria must consider the overall risk through the lifetime of a well.<br />

An evaluation of the surround<strong>in</strong>g environment, the effect of other <strong><strong>in</strong>stall</strong>ations <strong>in</strong> the area and<br />

the possibil<strong>it</strong>y for immediate help <strong>in</strong> case of emergency must be performed. The use of risk<br />

matrixes and superior cr<strong>it</strong>eria, e.g. maximum blowout frequency, provide a basis <strong>in</strong> a<br />

quantification of the environmental risk.<br />

F<strong>in</strong>ancial risk<br />

In a risk assessment the economic aspect will ma<strong>in</strong>ly be expressed by cost-efficient<br />

evaluations. The evaluations <strong>in</strong>clude a series of important parameters like material loss, loss of<br />

production and costs related <strong>to</strong> environmental damages. Compilation of acceptance cr<strong>it</strong>eria<br />

concern<strong>in</strong>g f<strong>in</strong>ancial risk is problematic. The risk analysis should ensure that the <strong><strong>in</strong>stall</strong>ation<br />

does not <strong>in</strong>volve an unacceptable high f<strong>in</strong>ancial risk as a result of an accident.<br />

3.1 The ALARP pr<strong>in</strong>ciple<br />

The ALARP-pr<strong>in</strong>ciple imply<strong>in</strong>g that the risk should be reduced <strong>to</strong> a level “as low as reasonably<br />

practicable” is widely used. ALARP is normally demonstrated us<strong>in</strong>g cost/benef<strong>it</strong> evaluations<br />

w<strong>it</strong>h risk reduc<strong>in</strong>g measures be<strong>in</strong>g implemented when e.g. the cost of avert<strong>in</strong>g a fatal<strong>it</strong>y are not<br />

prohib<strong>it</strong>ively high.<br />

Comb<strong>in</strong><strong>in</strong>g the acceptance cr<strong>it</strong>eria w<strong>it</strong>h the ALARP-pr<strong>in</strong>ciple solves acceptable risk problems<br />

[32]. It is compulsory for operat<strong>in</strong>g companies <strong>to</strong> def<strong>in</strong>e probabil<strong>it</strong>y values for certa<strong>in</strong><br />

Diploma thesis, <strong>NTNU</strong> 2002<br />

8