Onsite Use of Recycled Asphalt Pavement Materials and Geocells to ...

Onsite Use of Recycled Asphalt Pavement Materials and Geocells to ...

Onsite Use of Recycled Asphalt Pavement Materials and Geocells to ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

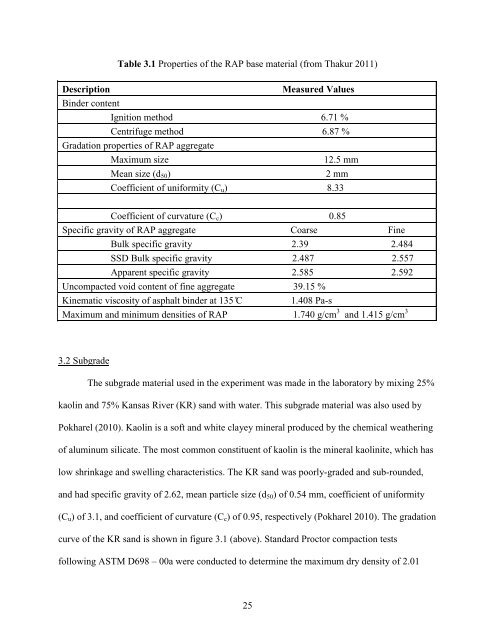

Table 3.1 Properties <strong>of</strong> the RAP base material (from Thakur 2011)<br />

Description Measured Values<br />

Binder content<br />

Ignition method 6.71 %<br />

Centrifuge method 6.87 %<br />

Gradation properties <strong>of</strong> RAP aggregate<br />

Maximum size 12.5 mm<br />

Mean size (d50) 2 mm<br />

Coefficient <strong>of</strong> uniformity (Cu) 8.33<br />

Coefficient <strong>of</strong> curvature (Cc) 0.85<br />

Specific gravity <strong>of</strong> RAP aggregate Coarse Fine<br />

Bulk specific gravity 2.39 2.484<br />

SSD Bulk specific gravity 2.487 2.557<br />

Apparent specific gravity 2.585 2.592<br />

Uncompacted void content <strong>of</strong> fine aggregate 39.15 %<br />

inematic viscosity <strong>of</strong> asphalt binder at 135 C 1.408 Pa-s<br />

Maximum <strong>and</strong> minimum densities <strong>of</strong> RAP 1.740 g/cm 3 <strong>and</strong> 1.415 g/cm 3<br />

3.2 Subgrade<br />

The subgrade material used in the experiment was made in the labora<strong>to</strong>ry by mixing 25%<br />

kaolin <strong>and</strong> 75% Kansas River (KR) s<strong>and</strong> with water. This subgrade material was also used by<br />

Pokharel (2010). Kaolin is a s<strong>of</strong>t <strong>and</strong> white clayey mineral produced by the chemical weathering<br />

<strong>of</strong> aluminum silicate. The most common constituent <strong>of</strong> kaolin is the mineral kaolinite, which has<br />

low shrinkage <strong>and</strong> swelling characteristics. The KR s<strong>and</strong> was poorly-graded <strong>and</strong> sub-rounded,<br />

<strong>and</strong> had specific gravity <strong>of</strong> 2.62, mean particle size (d50) <strong>of</strong> 0.54 mm, coefficient <strong>of</strong> uniformity<br />

(Cu) <strong>of</strong> 3.1, <strong>and</strong> coefficient <strong>of</strong> curvature (Cc) <strong>of</strong> 0.95, respectively (Pokharel 2010). The gradation<br />

curve <strong>of</strong> the KR s<strong>and</strong> is shown in figure 3.1 (above). St<strong>and</strong>ard Proc<strong>to</strong>r compaction tests<br />

following ASTM D698 – 00a were conducted <strong>to</strong> determine the maximum dry density <strong>of</strong> 2.01<br />

25