Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

F. Zhao et al. / Progress in Energy and Combustion Science 25 (1999) 437–562 539<br />

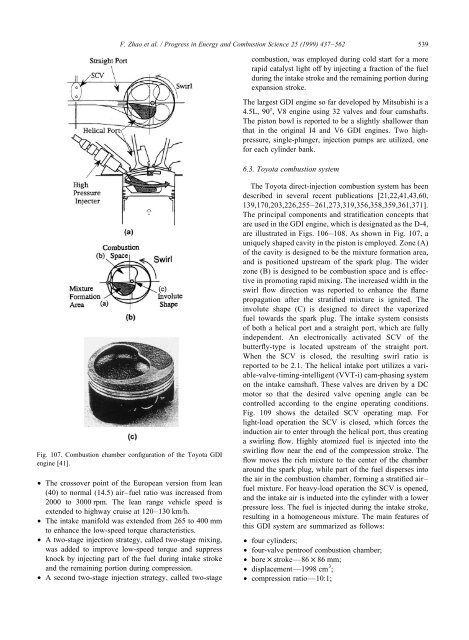

Fig. 107. Combustion chamber configuration of the Toyota GDI<br />

engine [41].<br />

• The crossover point of the European version from lean<br />

(40) to normal (14.5) air–fuel ratio was increased from<br />

2000 to 3000 rpm. The lean range vehicle speed is<br />

extended to highway cruise at 120–130 km/h.<br />

• The intake manifold was extended from 265 to 400 mm<br />

to enhance the low-speed torque characteristics.<br />

• A two-stage <strong>injection</strong> strategy, called two-stage mixing,<br />

was added to improve low-speed torque and suppress<br />

knock by injecting part of the fuel during intake stroke<br />

and the remaining portion during compression.<br />

• A second two-stage <strong>injection</strong> strategy, called two-stage<br />

combustion, was employed during cold start for a more<br />

rapid catalyst light off by injecting a fraction of the fuel<br />

during the intake stroke and the remaining portion during<br />

expansion stroke.<br />

The largest GDI engine so far developed by Mitsubishi is a<br />

4.5L, 90, V8 engine using 32 valves and four camshafts.<br />

The piston bowl is reported to be a slightly shallower than<br />

that in the original I4 and V6 GDI <strong>engines</strong>. Two highpressure,<br />

single-plunger, <strong>injection</strong> pumps are utilized, one<br />

for each cylinder bank.<br />

6.3. Toyota combustion system<br />

The Toyota <strong>direct</strong>-<strong>injection</strong> combustion system has been<br />

described in several recent publications [21,22,41,43,60,<br />

139,170,203,226,255–261,273,319,356,358,359,361,371].<br />

The principal components and stratification concepts that<br />

are used in the GDI engine, which is designated as the D-4,<br />

are illustrated in Figs. 106–108. As shown in Fig. 107, a<br />

uniquely shaped cavity in the piston is employed. Zone (A)<br />

of the cavity is designed to be the mixture formation area,<br />

and is positioned upstream of the <strong>spark</strong> plug. The wider<br />

zone (B) is designed to be combustion space and is effective<br />

in promoting rapid mixing. The increased width in the<br />

swirl flow <strong>direct</strong>ion was reported to enhance the flame<br />

propagation after the stratified mixture is <strong>ignited</strong>. The<br />

involute shape (C) is designed to <strong>direct</strong> the vaporized<br />

fuel towards the <strong>spark</strong> plug. The intake system consists<br />

of both a helical port and a straight port, which are fully<br />

independent. An electronically activated SCV of the<br />

butterfly-type is located upstream of the straight port.<br />

When the SCV is closed, the resulting swirl ratio is<br />

reported to be 2.1. The helical intake port utilizes a variable-valve-timing-intelligent<br />

(VVT-i) cam-phasing system<br />

on the intake camshaft. These valves are driven by a DC<br />

motor so that the desired valve opening angle can be<br />

controlled according to the engine operating conditions.<br />

Fig. 109 shows the detailed SCV operating map. For<br />

light-load operation the SCV is closed, which forces the<br />

induction air to enter through the helical port, thus creating<br />

a swirling flow. Highly atomized fuel is injected into the<br />

swirling flow near the end of the compression stroke. The<br />

flow moves the rich mixture to the center of the chamber<br />

around the <strong>spark</strong> plug, while part of the fuel disperses into<br />

the air in the combustion chamber, forming a stratified air–<br />

fuel mixture. For heavy-load operation the SCV is opened,<br />

and the intake air is inducted into the cylinder with a lower<br />

pressure loss. The fuel is injected during the intake stroke,<br />

resulting in a homogeneous mixture. The main features of<br />

this GDI system are summarized as follows:<br />

• four cylinders;<br />

• four-valve pentroof combustion chamber;<br />

• bore × stroke—86 × 86 mm;<br />

• displacement—1998 cm 3 ;<br />

• compression ratio—10:1;