Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

F. Zhao et al. / Progress in Energy and Combustion Science 25 (1999) 437–562 497<br />

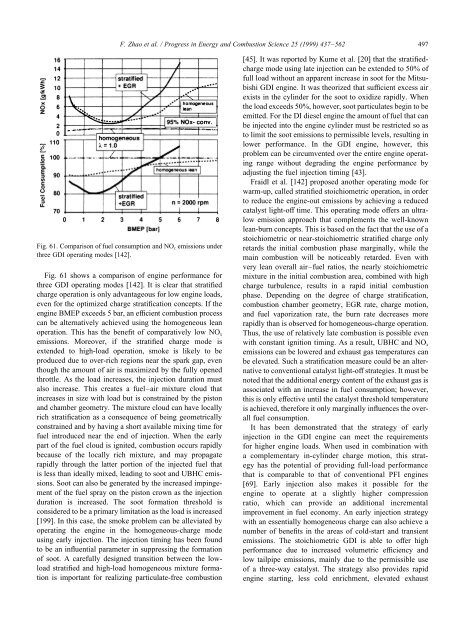

Fig. 61. Comparison of fuel consumption and NO x emissions under<br />

three GDI operating modes [142].<br />

Fig. 61 shows a comparison of engine performance for<br />

three GDI operating modes [142]. It is clear that stratified<br />

charge operation is only advantageous for low engine loads,<br />

even for the optimized charge stratification concepts. If the<br />

engine BMEP exceeds 5 bar, an efficient combustion process<br />

can be alternatively achieved using the homogeneous lean<br />

operation. This has the benefit of comparatively low NOx<br />

emissions. Moreover, if the stratified charge mode is<br />

extended to high-load operation, smoke is likely to be<br />

produced due to over-rich regions near the <strong>spark</strong> gap, even<br />

though the amount of air is maximized by the fully opened<br />

throttle. As the load increases, the <strong>injection</strong> duration must<br />

also increase. This creates a fuel–air mixture cloud that<br />

increases in size with load but is constrained by the piston<br />

and chamber geometry. The mixture cloud can have locally<br />

rich stratification as a consequence of being geometrically<br />

constrained and by having a short available mixing time for<br />

fuel introduced near the end of <strong>injection</strong>. When the early<br />

part of the fuel cloud is <strong>ignited</strong>, combustion occurs rapidly<br />

because of the locally rich mixture, and may propagate<br />

rapidly through the latter portion of the injected fuel that<br />

is less than ideally mixed, leading to soot and UBHC emissions.<br />

Soot can also be generated by the increased impingement<br />

of the fuel spray on the piston crown as the <strong>injection</strong><br />

duration is increased. The soot formation threshold is<br />

considered to be a primary limitation as the load is increased<br />

[199]. In this case, the smoke problem can be alleviated by<br />

operating the engine in the homogeneous-charge mode<br />

using early <strong>injection</strong>. The <strong>injection</strong> timing has been found<br />

to be an influential parameter in suppressing the formation<br />

of soot. A carefully designed transition between the lowload<br />

stratified and high-load homogeneous mixture formation<br />

is important for realizing particulate-free combustion<br />

[45]. It was reported by Kume et al. [20] that the stratifiedcharge<br />

mode using late <strong>injection</strong> can be extended to 50% of<br />

full load without an apparent increase in soot for the Mitsubishi<br />

GDI engine. It was theorized that sufficient excess air<br />

exists in the cylinder for the soot to oxidize rapidly. When<br />

the load exceeds 50%, however, soot particulates begin to be<br />

emitted. For the DI diesel engine the amount of fuel that can<br />

be injected into the engine cylinder must be restricted so as<br />

to limit the soot emissions to permissible levels, resulting in<br />

lower performance. In the GDI engine, however, this<br />

problem can be circumvented over the entire engine operating<br />

range without degrading the engine performance by<br />

adjusting the fuel <strong>injection</strong> timing [43].<br />

Fraidl et al. [142] proposed another operating mode for<br />

warm-up, called stratified stoichiometric operation, in order<br />

to reduce the engine-out emissions by achieving a reduced<br />

catalyst light-off time. This operating mode offers an ultralow<br />

emission approach that complements the well-known<br />

lean-burn concepts. This is based on the fact that the use of a<br />

stoichiometric or near-stoichiometric stratified charge only<br />

retards the initial combustion phase marginally, while the<br />

main combustion will be noticeably retarded. Even with<br />

very lean overall air–fuel ratios, the nearly stoichiometric<br />

mixture in the initial combustion area, combined with high<br />

charge turbulence, results in a rapid initial combustion<br />

phase. Depending on the degree of charge stratification,<br />

combustion chamber geometry, EGR rate, charge motion,<br />

and fuel vaporization rate, the burn rate decreases more<br />

rapidly than is observed for homogeneous-charge operation.<br />

Thus, the use of relatively late combustion is possible even<br />

with constant ignition timing. As a result, UBHC and NOx<br />

emissions can be lowered and exhaust gas temperatures can<br />

be elevated. Such a stratification measure could be an alternative<br />

to conventional catalyst light-off strategies. It must be<br />

noted that the additional energy content of the exhaust gas is<br />

associated with an increase in fuel consumption; however,<br />

this is only effective until the catalyst threshold temperature<br />

is achieved, therefore it only marginally influences the overall<br />

fuel consumption.<br />

It has been demonstrated that the strategy of early<br />

<strong>injection</strong> in the GDI engine can meet the requirements<br />

for higher engine loads. When used in combination with<br />

a complementary in-cylinder charge motion, this strategy<br />

has the potential of providing full-load performance<br />

that is comparable to that of conventional PFI <strong>engines</strong><br />

[69]. Early <strong>injection</strong> also makes it possible for the<br />

engine to operate at a slightly higher compression<br />

ratio, which can provide an additional incremental<br />

improvement in fuel economy. An early <strong>injection</strong> strategy<br />

with an essentially homogeneous charge can also achieve a<br />

number of benefits in the areas of cold-start and transient<br />

emissions. The stoichiometric GDI is able to offer high<br />

performance due to increased volumetric efficiency and<br />

low tailpipe emissions, mainly due to the permissible use<br />

of a three-way catalyst. The strategy also provides rapid<br />

engine starting, less cold enrichment, elevated exhaust