Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

496<br />

F. Zhao et al. / Progress in Energy and Combustion Science 25 (1999) 437–562<br />

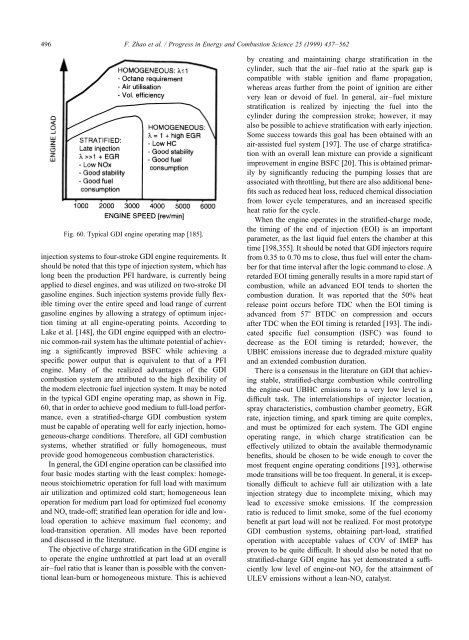

Fig. 60. Typical GDI engine operating map [185].<br />

<strong>injection</strong> systems to four-stroke GDI engine requirements. It<br />

should be noted that this type of <strong>injection</strong> system, which has<br />

long been the production PFI hardware, is currently being<br />

applied to diesel <strong>engines</strong>, and was utilized on two-stroke DI<br />

<strong>gasoline</strong> <strong>engines</strong>. Such <strong>injection</strong> systems provide fully flexible<br />

timing over the entire speed and load range of current<br />

<strong>gasoline</strong> <strong>engines</strong> by allowing a strategy of optimum <strong>injection</strong><br />

timing at all engine-operating points. According to<br />

Lake et al. [148], the GDI engine equipped with an electronic<br />

common-rail system has the ultimate potential of achieving<br />

a significantly improved BSFC while achieving a<br />

specific power output that is equivalent to that of a PFI<br />

engine. Many of the realized advantages of the GDI<br />

combustion system are attributed to the high flexibility of<br />

the modern electronic fuel <strong>injection</strong> system. It may be noted<br />

in the typical GDI engine operating map, as shown in Fig.<br />

60, that in order to achieve good medium to full-load performance,<br />

even a stratified-charge GDI combustion system<br />

must be capable of operating well for early <strong>injection</strong>, homogeneous-charge<br />

conditions. Therefore, all GDI combustion<br />

systems, whether stratified or fully homogeneous, must<br />

provide good homogeneous combustion characteristics.<br />

In general, the GDI engine operation can be classified into<br />

four basic modes starting with the least complex: homogeneous<br />

stoichiometric operation for full load with maximum<br />

air utilization and optimized cold start; homogeneous lean<br />

operation for medium part load for optimized fuel economy<br />

and NO x trade-off; stratified lean operation for idle and lowload<br />

operation to achieve maximum fuel economy; and<br />

load-transition operation. All modes have been reported<br />

and discussed in the literature.<br />

The objective of charge stratification in the GDI engine is<br />

to operate the engine unthrottled at part load at an overall<br />

air–fuel ratio that is leaner than is possible with the conventional<br />

lean-burn or homogeneous mixture. This is achieved<br />

by creating and maintaining charge stratification in the<br />

cylinder, such that the air–fuel ratio at the <strong>spark</strong> gap is<br />

compatible with stable ignition and flame propagation,<br />

whereas areas further from the point of ignition are either<br />

very lean or devoid of fuel. In general, air–fuel mixture<br />

stratification is realized by injecting the fuel into the<br />

cylinder during the compression stroke; however, it may<br />

also be possible to achieve stratification with early <strong>injection</strong>.<br />

Some success towards this goal has been obtained with an<br />

air-assisted fuel system [197]. The use of charge stratification<br />

with an overall lean mixture can provide a significant<br />

improvement in engine BSFC [20]. This is obtained primarily<br />

by significantly reducing the pumping losses that are<br />

associated with throttling, but there are also additional benefits<br />

such as reduced heat loss, reduced chemical dissociation<br />

from lower cycle temperatures, and an increased specific<br />

heat ratio for the cycle.<br />

When the engine operates in the stratified-charge mode,<br />

the timing of the end of <strong>injection</strong> (EOI) is an important<br />

parameter, as the last liquid fuel enters the chamber at this<br />

time [198,355]. It should be noted that GDI injectors require<br />

from 0.35 to 0.70 ms to close, thus fuel will enter the chamber<br />

for that time interval after the logic command to close. A<br />

retarded EOI timing generally results in a more rapid start of<br />

combustion, while an advanced EOI tends to shorten the<br />

combustion duration. It was reported that the 50% heat<br />

release point occurs before TDC when the EOI timing is<br />

advanced from 57 BTDC on compression and occurs<br />

after TDC when the EOI timing is retarded [193]. The indicated<br />

specific fuel consumption (ISFC) was found to<br />

decrease as the EOI timing is retarded; however, the<br />

UBHC emissions increase due to degraded mixture quality<br />

and an extended combustion duration.<br />

There is a consensus in the literature on GDI that achieving<br />

stable, stratified-charge combustion while controlling<br />

the engine-out UBHC emissions to a very low level is a<br />

difficult task. The interrelationships of injector location,<br />

spray characteristics, combustion chamber geometry, EGR<br />

rate, <strong>injection</strong> timing, and <strong>spark</strong> timing are quite complex,<br />

and must be optimized for each system. The GDI engine<br />

operating range, in which charge stratification can be<br />

effectively utilized to obtain the available thermodynamic<br />

benefits, should be chosen to be wide enough to cover the<br />

most frequent engine operating conditions [193], otherwise<br />

mode transitions will be too frequent. In general, it is exceptionally<br />

difficult to achieve full air utilization with a late<br />

<strong>injection</strong> strategy due to incomplete mixing, which may<br />

lead to excessive smoke emissions. If the compression<br />

ratio is reduced to limit smoke, some of the fuel economy<br />

benefit at part load will not be realized. For most prototype<br />

GDI combustion systems, obtaining part-load, stratified<br />

operation with acceptable values of COV of IMEP has<br />

proven to be quite difficult. It should also be noted that no<br />

stratified-charge GDI engine has yet demonstrated a sufficiently<br />

low level of engine-out NOx for the attainment of<br />

ULEV emissions without a lean-NO x catalyst.