Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

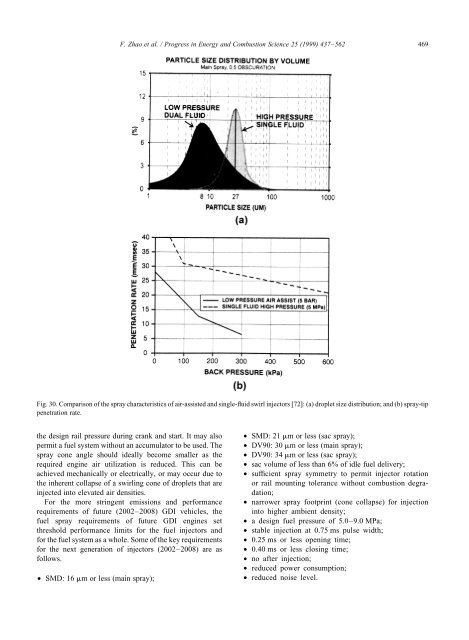

the design rail pressure during crank and start. It may also<br />

permit a fuel system without an accumulator to be used. The<br />

spray cone angle should ideally become smaller as the<br />

required engine air utilization is reduced. This can be<br />

achieved mechanically or electrically, or may occur due to<br />

the inherent collapse of a swirling cone of droplets that are<br />

injected into elevated air densities.<br />

For the more stringent emissions and performance<br />

requirements of future (2002–2008) GDI vehicles, the<br />

fuel spray requirements of future GDI <strong>engines</strong> set<br />

threshold performance limits for the fuel injectors and<br />

for the fuel system as a whole. Some of the key requirements<br />

for the next generation of injectors (2002–2008) are as<br />

follows.<br />

• SMD: 16 mm or less (main spray);<br />

F. Zhao et al. / Progress in Energy and Combustion Science 25 (1999) 437–562 469<br />

Fig. 30. Comparison of the spray characteristics of air-assisted and single-fluid swirl injectors [72]: (a) droplet size distribution; and (b) spray-tip<br />

penetration rate.<br />

• SMD: 21 mm or less (sac spray);<br />

• DV90: 30 mm or less (main spray);<br />

• DV90: 34 mm or less (sac spray);<br />

• sac volume of less than 6% of idle fuel delivery;<br />

• sufficient spray symmetry to permit injector rotation<br />

or rail mounting tolerance without combustion degradation;<br />

• narrower spray footprint (cone collapse) for <strong>injection</strong><br />

into higher ambient density;<br />

• a design fuel pressure of 5.0–9.0 MPa;<br />

• stable <strong>injection</strong> at 0.75 ms pulse width;<br />

• 0.25 ms or less opening time;<br />

• 0.40 ms or less closing time;<br />

• no after <strong>injection</strong>;<br />

• reduced power consumption;<br />

• reduced noise level.